Acrylonitrile polymer aqueous phase suspension production system and method for PNA carbon fiber precursor

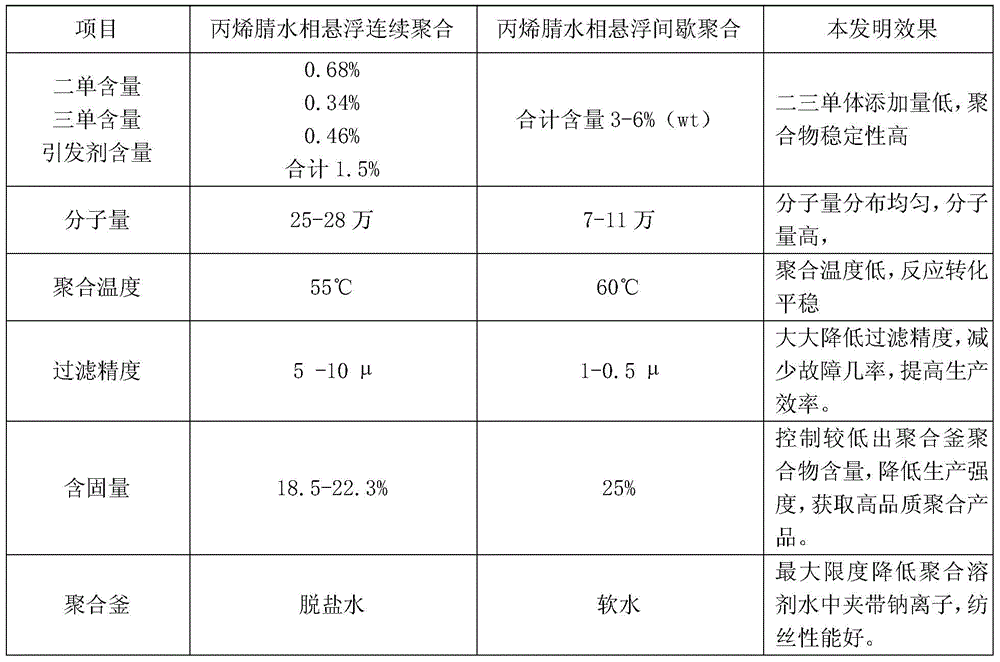

A carbon fiber precursor and water suspension technology, which is applied to the production system and the field of acrylonitrile polymer aqueous suspension for PNA carbon fiber precursor, can solve the problem of unstable polyacrylonitrile precursor polymerization process, low polymer molecular weight, low molecular weight, Problems such as the large dispersibility of raw silk between batches, to achieve the effect of good molecular weight uniformity, reduction of terminal defects, and small fluctuation of molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

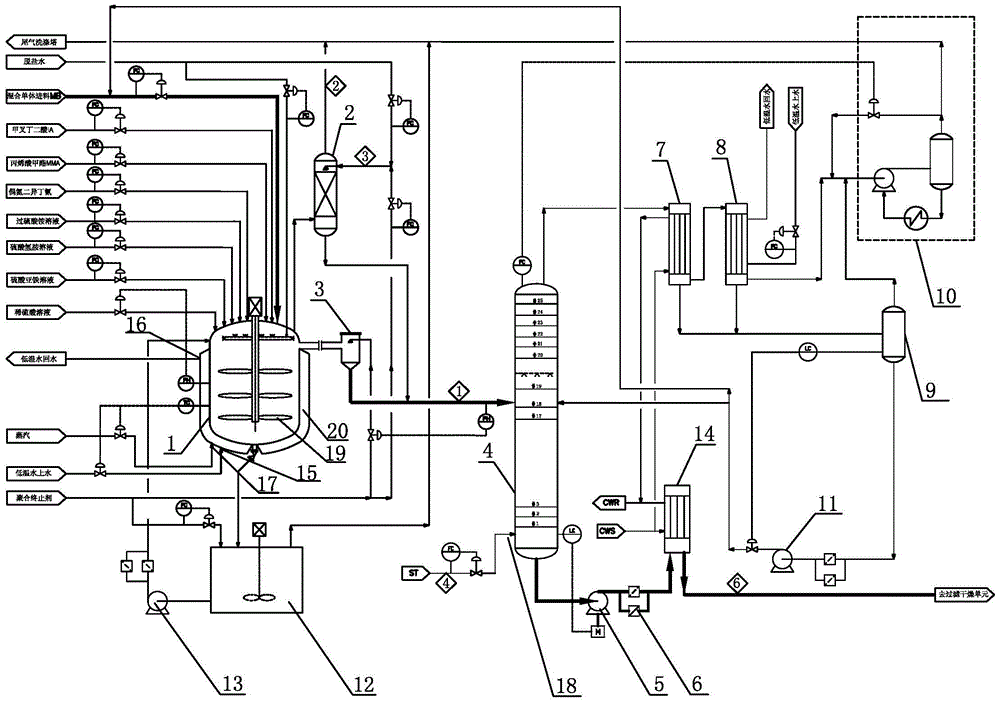

[0042] A kind of PNA carbon fiber precursor uses acrylonitrile polymer aqueous suspension production system, such as figure 1 As shown, it includes polymerization kettle 1, polymerization vent scrubber 2, overflow tank 3, single removal tower 4, single removal tower bottom pump 5, candle filter 6, single removal tower primary condenser 7, single removal tower Secondary condenser 8, single tower reflux tank 9, single tower vacuum system 10 and single tower reflux pump 11, the upper end of the polymerization kettle 1 is provided with several material inlets, the top gas outlet of the polymerization kettle 1 is connected with the polymerization vent washing The gas inlet at the lower end of the device 2 is connected, the upper material outlet of the polymerizer 1 is connected with the upper material inlet of the overflow tank 3, and the bottom material outlet of the polymerization vent scrubber 2 and the bottom material outlet of the overflow tank 3 are respectively connected with...

specific Embodiment 2

[0044] A kind of PNA carbon fiber precursor is suspended production method with acrylonitrile polymer aqueous phase, as figure 1 shown, including the following steps:

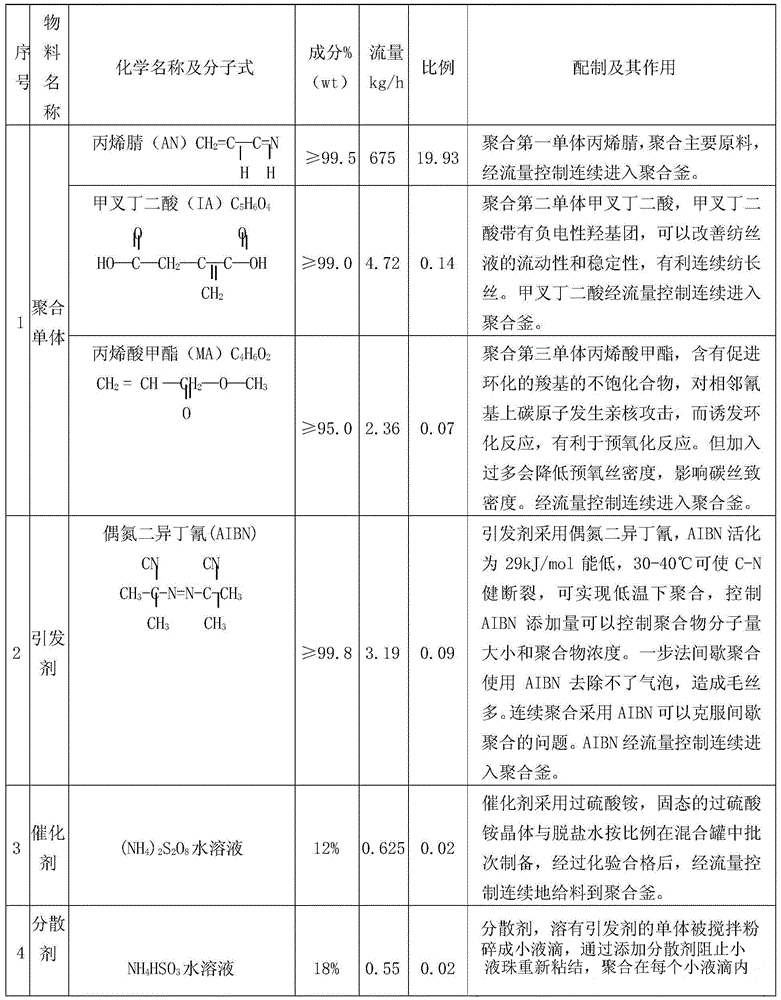

[0045] (1) The monomers, initiators, catalysts, dispersants, pH regulators and desalted water are continuously sent into the polymerization kettle 1 according to a certain flow rate respectively, wherein the raw material components and flow rates of the monomers are as follows: the first monomer acrylonitrile 675kg / h, the second monomer methylene succinic acid 4.72kg / h and the third monomer methyl acrylate 2.36kg / h; the initiator raw material composition and flow rate are azobisisobutylcyanide 3.19kg / h; the catalyst raw material composition And flow rate is 12wt% ammonium persulfate solution 0.625kg / h; Dispersant raw material composition and flow rate are as follows: 18wt% ammonium bisulfite solution 0.55kg / h and 7wt% ferrous sulfate solution 0.16kg / h; pH regulator is 20wt % dilute sulfuric acid solution 0.42...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com