Microbe-assisted synthesis and degradable oil-water separation omentum and preparation method thereof

A technology of oil-water separation omentum and microorganisms, which is applied in the field of oil-water separation omentum and its preparation, can solve the problems of restricting large-scale practical application, poor water resistance of omentum, and affecting service life, so as to improve the oil-water separation effect and separation performance Stable, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

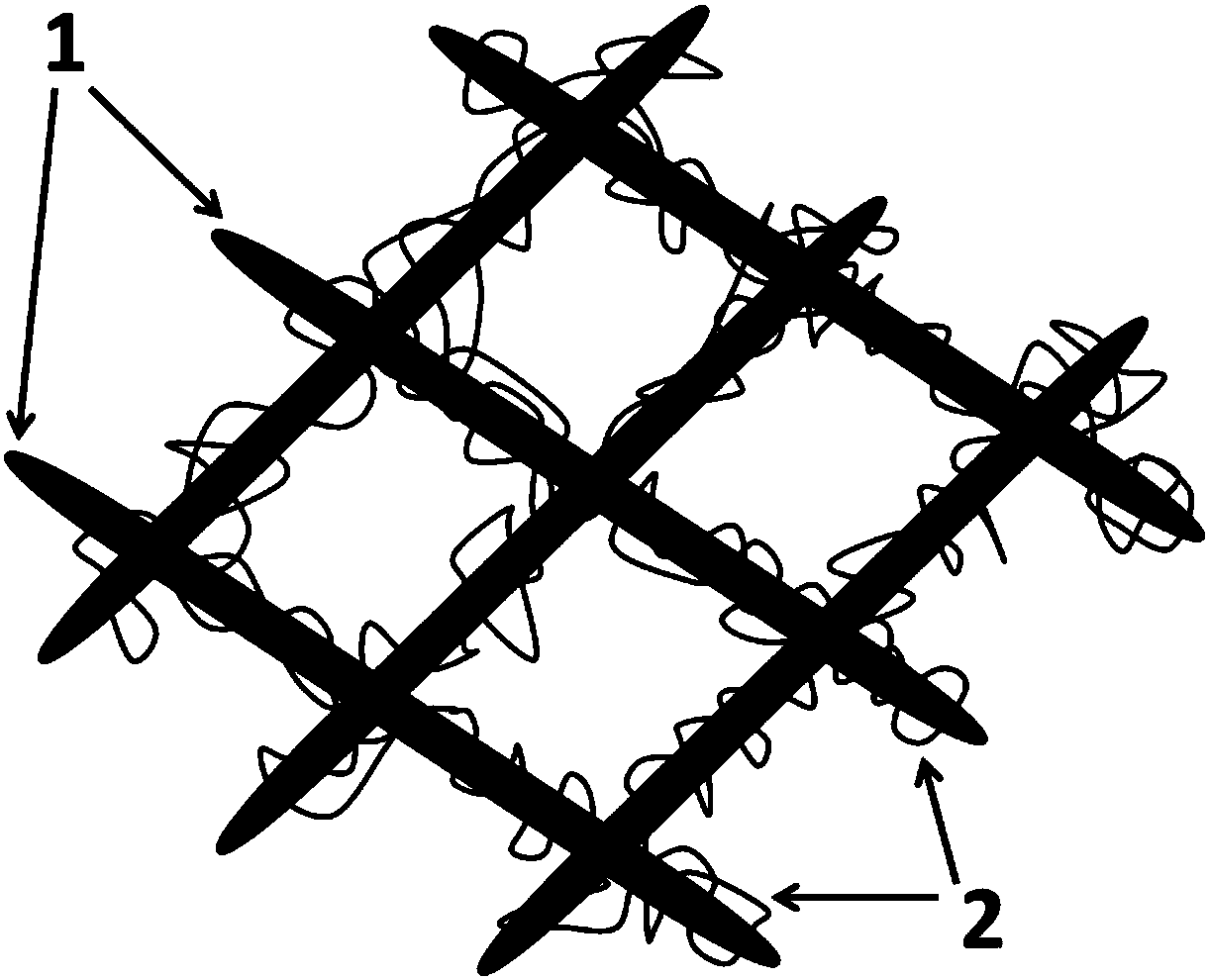

Image

Examples

preparation example Construction

[0020] The preparation method of the degradable oil-water separation omentum that is assisted by microorganisms to be synthesized by the present invention comprises the following steps:

[0021] (1) Microbial liquid seed medium and microbial solid-state fermentation medium are prepared respectively:

[0022] Preparation of microbial liquid seed medium:

[0023] Add 2% glucose, 0.5% peptone, 0.5% yeast powder, 0.27% disodium hydrogen phosphate pentahydrate and 0.115% citric acid-hydrate with a mass concentration of less than 3 g / L in deionized water according to the following mass percentages. Sulfuric acid with a percentage concentration of 0.2% adjusts the pH value to 4-6, sterilizes at 115 degrees Celsius for 30 minutes, and shakes fully to obtain a microbial liquid seed medium;

[0024] Preparation of microbial solid-state fermentation medium:

[0025] Add 2% glucose, 0.5% peptone, 0.5% yeast powder, 0.27% disodium hydrogen phosphate pentahydrate, 0.2% agar and 0.115 citr...

Embodiment 1

[0033] (1) Preparation of microbial fermentation medium:

[0034] Preparation of microbial liquid seed medium:

[0035] Add 2% glucose, 0.5% peptone, 0.5% yeast powder, 0.27% disodium hydrogen phosphate pentahydrate and 0.115% citric acid-hydrate with a mass concentration of less than 3 g / L to 250 mL of deionized water in the following mass percentages to Sulfuric acid with a mass concentration of 0.2% adjusts the pH value to 5, sterilizes at 115 degrees centigrade for 30 minutes, and vibrates fully to obtain a microbial liquid seed medium for use.

[0036] Preparation of microbial solid-state fermentation medium:

[0037]Add 2% glucose, 0.5% peptone, 0.5% yeast powder, 0.27% disodium hydrogen phosphate pentahydrate, 0.2% agar and citric acid-water with a mass concentration of less than 3 g / L to 60 mL of deionized water according to the following mass percentages: 0.115% of the compound was adjusted to pH 5 with sulfuric acid with a mass concentration of 0.2%, sterilized at ...

Embodiment 2

[0044] (1) Prepare liquid seed medium and solid-state fermentation medium of microbial strains according to the method in Example 1.

[0045] (2) Inoculate the commercial Acetobacter xylinum strain into the seed culture medium with an incorporation amount of 2%, and vibrate at 30 degrees Celsius for 24 hours to obtain a seed culture solution.

[0046] (3) Cut the sterilized cotton gauze into a 4cm × 6cm size sample, spread it on the surface of the microbial solid-state fermentation medium prepared in the above step (1), wherein the yarn count in the cotton gauze is 30 The yarn count density is 50×60.

[0047] (4) the seed culture liquid of the Acetobacter xylinum bacterial classification that step (2) gained is added dropwise on the cotton gauze in step (3), until gauze is soaked completely, at 30 degrees Celsius, static culture 24 hours.

[0048] (5) Place the composite membrane obtained in step (4) in 6% sodium hydroxide aqueous solution at 80 degrees Celsius for 40 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com