Zero emission process for treating kitchen wastes

A technology of kitchen waste and zero discharge, applied in waste treatment, water/sewage treatment, anaerobic digestion treatment, etc., can solve the problems of no good cases and small application range, and achieve the effect of reducing scale and solving outlet problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

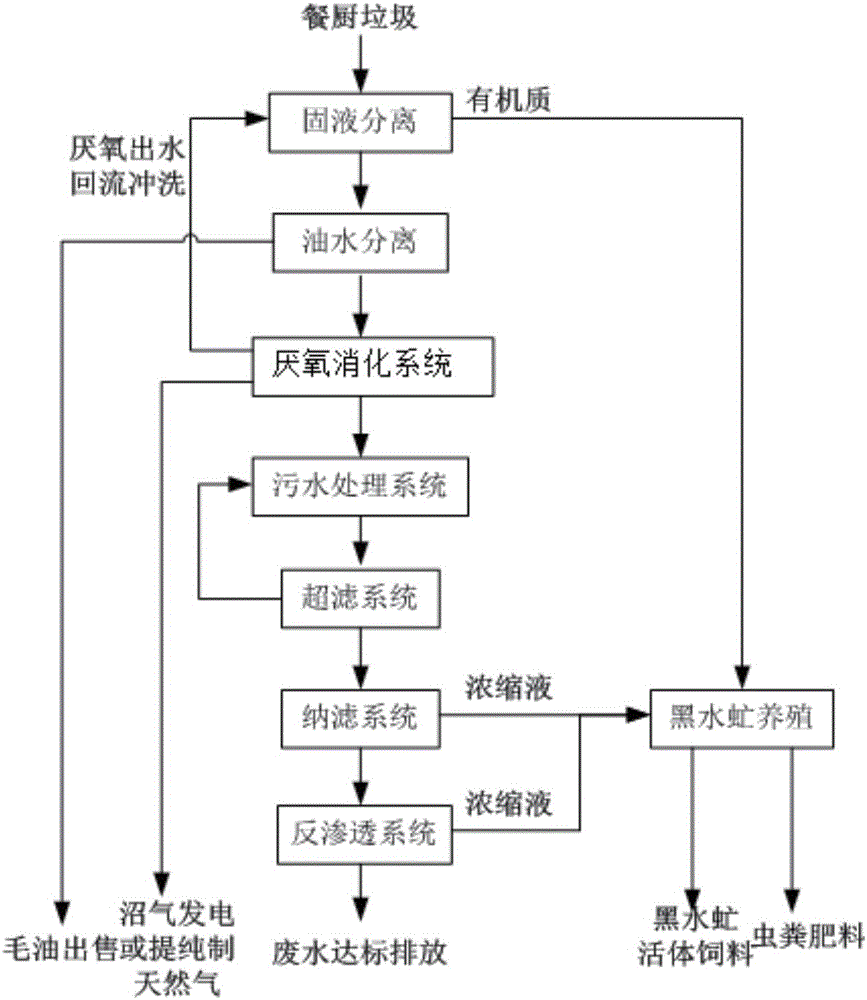

[0027] see figure 1 , the zero-discharge process of kitchen waste treatment of the present invention comprises the following steps:

[0028] (1) Solid-liquid separation is carried out on the kitchen waste through the rotating fine grid, and the organic matter separated from the solid-liquid enters the black soldier fly breeding system, and the black soldier fly is cultivated to obtain the black soldier fly live feed and insect excrement waste;

[0029] (2) The liquid phase obtained by solid-liquid separation en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com