Full-color sandstone dye for 3DP (three dimensional printing) and forming method of full-color sandstone dye product

A dye and sandstone technology, which is applied in the molding field of full-color sandstone dyes for 3DP printing and its products, can solve the problems of not meeting the requirements of low cost, and achieve the effects of high production efficiency, short molding cycle and strong designability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

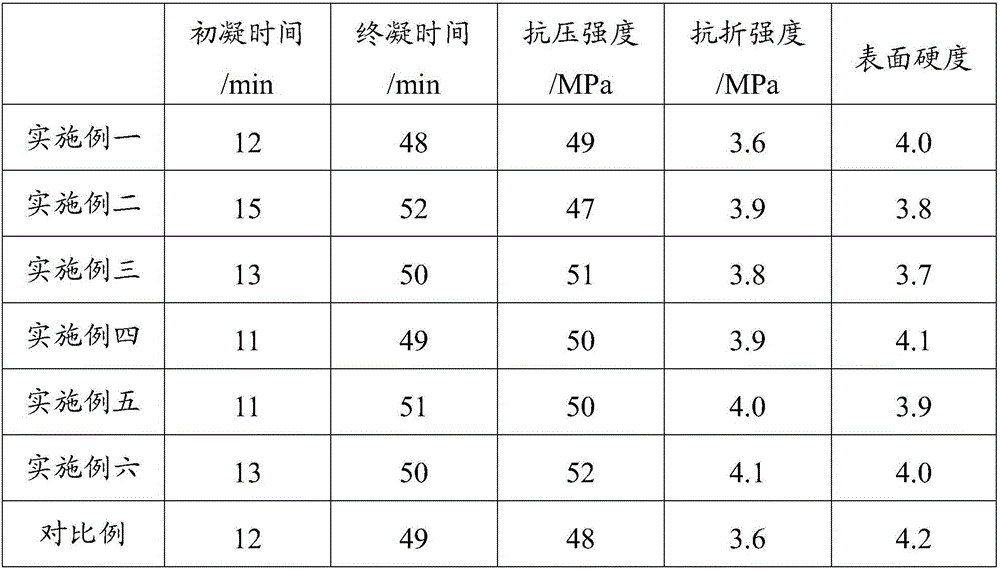

Examples

preparation example Construction

[0027] The preparation technology of full-color sandstone dyestuff comprises the following steps:

[0028] 1. Prepare a solution of 8.0% to 20.0% binder by commercially available binder and pure water, and heat at 80~150°C for 0.1~10h under the stirring condition of 50~300r / min to prepare the binder; add 4N Sodium hydroxide aqueous solution, adjust the pH to 9.5-10.0, according to the mass ratio of the dye powder and the deionized water as 1:1, under the condition of 200-1000r / min, mechanically stir for 0.5-5.0h, Get Dye Supplies for Full Color Sandstone Dye.

[0029] 2. According to the mass percentage of each component of the raw material of the full-color sandstone product, weigh 60.0% to 85.0% of the main powder and 2.0% to 15.0% of the coagulant and add them to the mechanical mixing equipment in sequence in proportion, and mix them evenly by ball milling. Makes a powder of full-color sandstone dye. Wherein, the main powder and the coagulant are both commercially available...

Embodiment 1

[0036] 1. Weigh 0.24Kg of cornstarch, add 2.76Kg of deionized water to the beaker according to the ratio of cornstarch mass content of 8.0%, place the heating temperature at 115°C and the stirring speed at 175r / min, heat treatment for 5.0h, A starch solution is obtained. After slowly cooling down to room temperature, prepare it.

[0037] 2. Add the dye slurry consisting of 1.5Kg of C.I reactive red 218 and 1.5Kg of deionized water to the solution in step 1, and then continue to add 4N aqueous sodium hydroxide solution to adjust the pH of the solution to 9.5-10.0. Stir for 5.0 hours at a speed of 200 r / min to obtain a uniformly mixed full-color sandstone dye consumable.

[0038] Three, the preparation of full-color sandstone dye powder, according to the ratio that mass content accounts for sandstone powder consumable 60.0% and 15.0%, the purity after drying is 4.8Kg of 200 mesh calcium carbonate of 95.0%, 1.2Kg of aluminum sulfate of 98.0%, successively Put it into the QM-2SP...

Embodiment 2

[0043] One, take by weighing 0.42Kg potato starch, according to the ratio that potato starch mass content is 14.0%, add 2.58Kg deionized water in the beaker, place heating temperature 80 ℃, under the condition of stirring speed 300r / min, heat treatment 0.1h, A potato starch solution is obtained. After slowly cooling down to room temperature, prepare it.

[0044] 2. Add the dye slurry consisting of 1.5Kg of C.I reactive red 218 and 1.5Kg of deionized water to the solution in step 1, and then continue to add 4N aqueous sodium hydroxide solution to adjust the pH of the solution to 9.5-10.0. Stir for 2.7 hours at a speed of 600r / min to obtain a uniformly mixed full-color sandstone dye consumable.

[0045] Three, the preparation of full-color sandstone dye powder, according to the ratio of mass content accounting for sandstone powder consumables 85.0% and 2.0%, the purity after drying is 6.8Kg of 800 mesh gypsum powder of 99.0%, 0.16Kg of potassium sulfate of 99.5%, successively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com