Super plasticizer for three-dimensional printing house slurry

A 3D printing and superplasticizer technology, applied in the direction of additive processing, etc., to achieve the effect of improving the workability of slurry, improving pumpability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

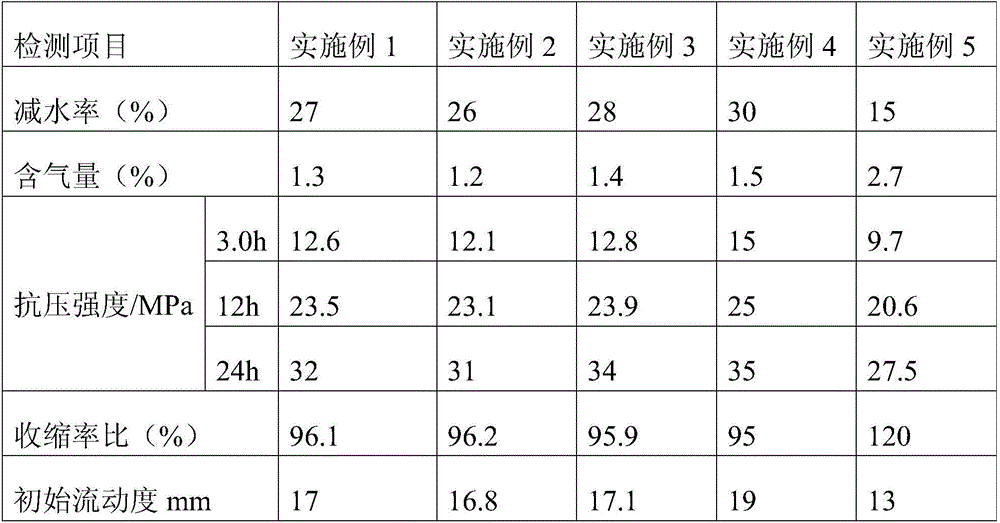

Examples

Embodiment 1

[0018] A kind of superplasticizer for 3D printing house slurry, take kg as the unit, weigh the required raw materials of each component: sodium lignosulfonate 10kg, lubricant bentonite 10kg, sodium sulfate 1kg, 3-[(2,4 -dichloro)phenyl]-2-acrylic acid 0.1kg, ammonium chloride 0.01kg, ammonium dihydrogen phosphate 0.01kg, additive 0.5kg and pentadecylphenol 0.001kg; Wherein, additive is by syrup 10kg, tannic acid 5kg , 5kg of turpentine, 1kg of disodium edetate and 8kg of ethanol. Mix the raw materials of the above-mentioned components obtained by weighing, and stir evenly to obtain the product.

Embodiment 2

[0020] A kind of superplasticizer for 3D printing house slurry, take kg as the unit, weigh the required raw materials of each component: sodium lignosulfonate 30kg, lubricant silica gel 15kg, sodium sulfate 2kg, 3-[(2,4 -dichloro)phenyl]-2-acrylic acid 0.3kg, ammonium chloride 0.03kg, ammonium dihydrogen phosphate 0.03kg, additive 2.5kg and pentadecylphenol 0.002kg; Wherein, additive is by syrup 20kg, tannin 7kg , 7kg of turpentine, 3kg of disodium edetate and 12kg of ethanol. Mix the raw materials of the above-mentioned components obtained by weighing, and stir evenly to obtain the product.

Embodiment 3

[0022] A kind of superplasticizer for 3D printing house slurry, take kg as the unit, take by weighing required raw materials of each component: sodium lignosulfonate 20kg, lubricant castor oil 12.5kg, sodium sulfate 1.5kg, 3-[( 0.2kg of 2,4-dichloro)phenyl]-2-acrylic acid, 0.02kg of ammonium chloride, 0.02kg of ammonium dihydrogen phosphate, 1.5kg of additives and 0.001kg of pentadecylphenol; wherein, the additives consist of 15kg of starch syrup, dandelion 6kg of nic acid, 6kg of turpentine, 2kg of disodium edetate and 10kg of ethanol. Mix the raw materials of the above-mentioned components obtained by weighing, and stir evenly to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com