Luminescent inorganic dry powder coating

A technology of inorganic dry powder and luminescent material, applied in the field of building mortar, can solve the problems of poor compatibility and limit the color range of decorative mortar, and achieve the effect of improving decorative effect, good decorative performance and resisting degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

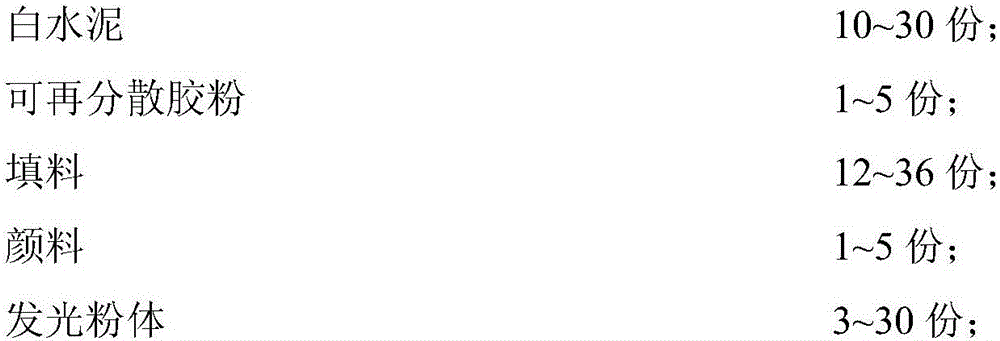

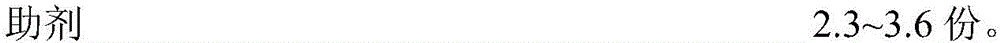

Method used

Image

Examples

Embodiment 1

[0029] Add 15 parts of white Portland cement, 3 parts of metakaolin, 3 parts of rutile titanium dioxide, 2 parts of iron oxide red, 10 parts of calcium carbonate, 1 part of diatomaceous earth, 5 parts of silica powder, and aluminosilicate into the dispersion equipment 3 parts of strontium luminescent powder, 0.2 part of water reducing agent; 0.2 part of defoamer; 0.4 part of cellulose ether; 0.2 part of starch ether; 1 part of antibacterial agent, 0.3 part of antifungal agent and 3 parts of redispersible rubber powder Uniformly and filtered through a sieve to obtain the luminescent inorganic dry powder coating product of the present invention.

Embodiment 2

[0031] Add 10 parts of white sulfoaluminate cement, 3 parts of metakaolin, 3 parts of iron oxide yellow, 5 parts of calcium carbonate, 12 parts of silicon micropowder, 10 parts of barium aluminate luminescent powder, and 0.1 part of water reducing agent into the dispersion equipment; 0.1 part of defoaming agent; 1 part of cellulose ether; 0.1 part of starch ether; 2 parts of antibacterial agent, 0.3 part of antifungal agent and 1 part of redispersible rubber powder, stir evenly and filter through a sieve to obtain the luminescent inorganic dry powder of the present invention Paint products.

Embodiment 3

[0033] Add 25 parts of white aluminate cement, 10 parts of metakaolin, 1 part of iron oxide black, 15 parts of calcium carbonate, 3 parts of diatomaceous earth, 8 parts of silicon micropowder, 20 parts of magnesium silicate luminescent powder, and 0.3 part of water agent; 0.6 part of defoamer; 0.1 part of cellulose ether; 0.2 part of starch ether; 2 parts of antibacterial agent, 0.3 part of antifungal agent and 5 parts of redispersible rubber powder, stir evenly and filter through a sieve to obtain The luminescent inorganic dry powder coating product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com