Method for purifying high-quality acarbose

A technology of acarbose and a purification method, which is applied in the field of pharmaceutical purification, can solve the problems of large amount of elution solvent, low yield of acarbose, and poor desalination effect, so as to save organic solvents and energy consumption, save The effect of eliminating the column packing step and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 10 tons of the pretreated acarbose fermentation liquid, the concentration is 0.6% (W / W), and the pH value is adjusted to 4.8 with filter aid aluminum sulfate.

[0047] The elution temperature of the anion and cation exchange resin column chromatography in this embodiment is 20°C.

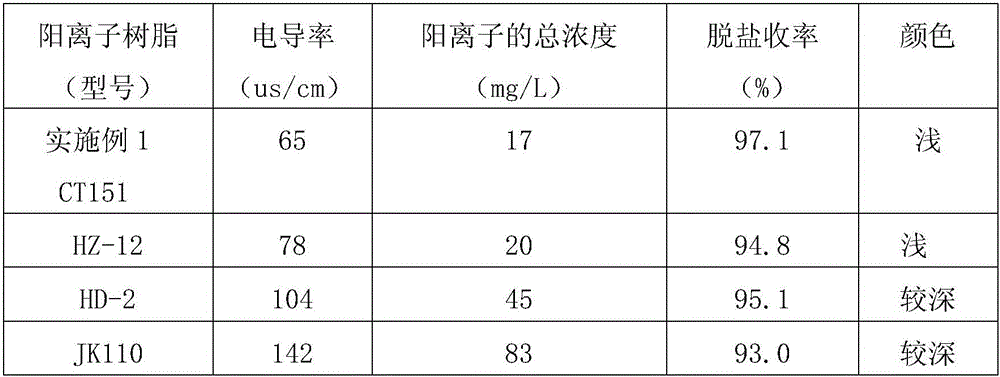

[0048] Add strong acidic cation exchange resin chromatography column (filler: CT151, chromatography column inner diameter: 1000mm; filling height: 2500mm), pass through the cation exchange resin chromatography column at a volume of 1 times per hour, and collect 12000 liters of feed liquid .

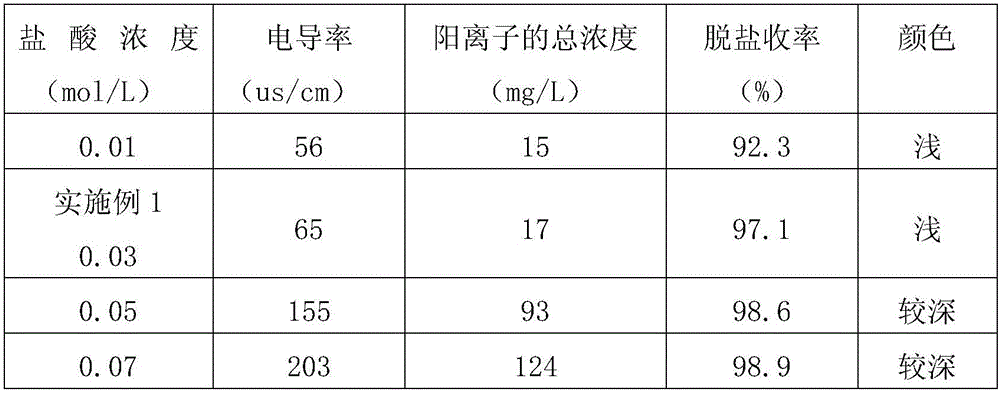

[0049] Lower the liquid level to about 10cm above the resin surface, then pass through 1.5 times the volume of 0.03mol / L hydrochloric acid to top wash the resin at a rate of 1 times the volume per hour, and collect 3000 liters of eluent.

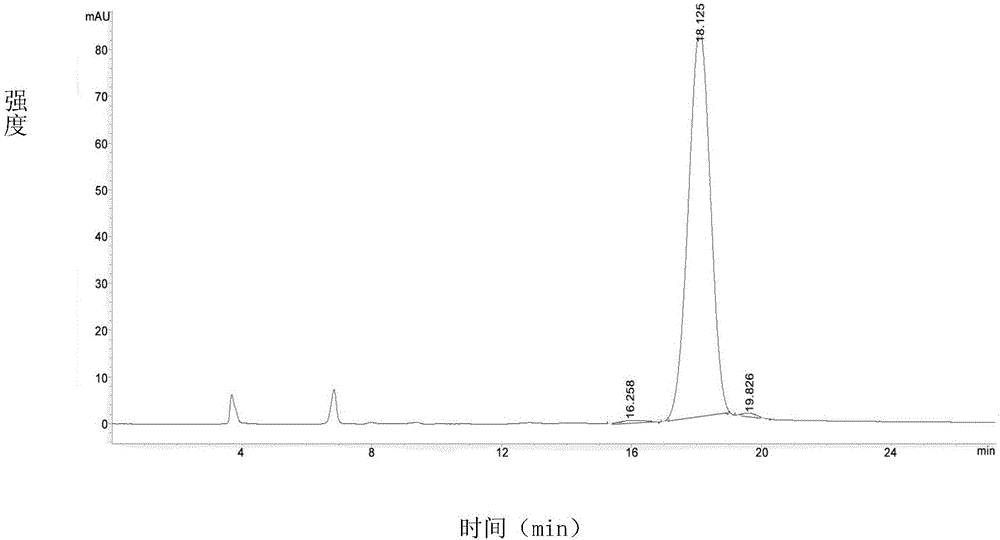

[0050] The mixture of the above feed liquid and eluent is determined by ion chromatography for Ca 2+ 、Na + The total concentration of cations was 17mg / L.

[0051] ...

Embodiment 2

[0061] 10 tons of the pretreated acarbose fermentation liquid, the concentration is 0.5% (W / W), and the pH value is adjusted to 4.5 with filter aid aluminum sulfate.

[0062] The elution temperature of the anion and cation exchange resin column chromatography in this embodiment is 25°C.

[0063] Add strong acidic cation exchange resin chromatography column (filler: HZ-12, chromatography column inner diameter: 1000mm; filling height: 2000mm), pass through the cation exchange resin chromatography column at a volume of 0.5 times per hour, and collect the feed liquid 9500 liters.

[0064] Lower the liquid level to about 10cm above the resin surface, then feed 1 volume of 0.04mol / L hydrochloric acid to top wash the resin at a rate of 1.5 volumes per hour, and collect 2000 liters of eluent.

[0065] The mixture of the above feed liquid and eluent is determined by ion chromatography for Ca 2+ 、Na + The total concentration of cations is 25mg / L.

[0066] Pass 9500 liters of feed li...

Embodiment 3

[0070] 10 tons of the pretreated acarbose fermentation liquid, the concentration is 0.7% (W / W), and the pH value is adjusted to 4.9 with filter aid aluminum sulfate.

[0071] The elution temperature of the anion and cation exchange resin column chromatography in this embodiment is 15°C.

[0072] Add strong acidic cation exchange resin chromatography column (filler: JK006, column inner diameter: 1000mm; filling height: 3000mm), pass through the cation exchange resin chromatography column at 1.5 times the volume per hour, and collect 9400 liters of feed liquid .

[0073] Lower the liquid level to about 10cm above the resin surface, then pass through 2 times the volume of 0.02mol / L hydrochloric acid to top wash the resin at a rate of 0.5 times the volume per hour, and collect 4000 liters of eluent.

[0074] The mixture of the above feed liquid and eluent is determined by ion chromatography for Ca 2+ 、Na + The total concentration of cations was 27mg / L.

[0075] Pass 9400 liter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com