Preparation method of tackifier used for organosilicone LED packaging colloidal system

A LED encapsulation and tackifier technology, applied in adhesives, polymer adhesive additives, adhesive additives, etc., can solve problems such as Pt catalyst poisoning, achieve improved adhesion, strong operability, and good mutual solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

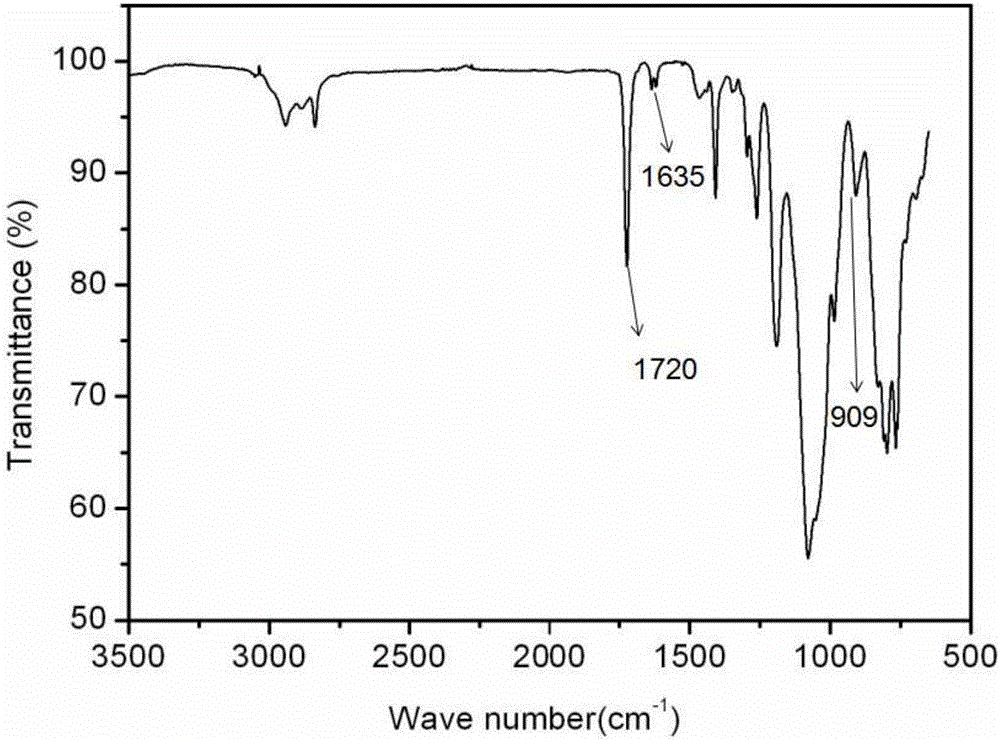

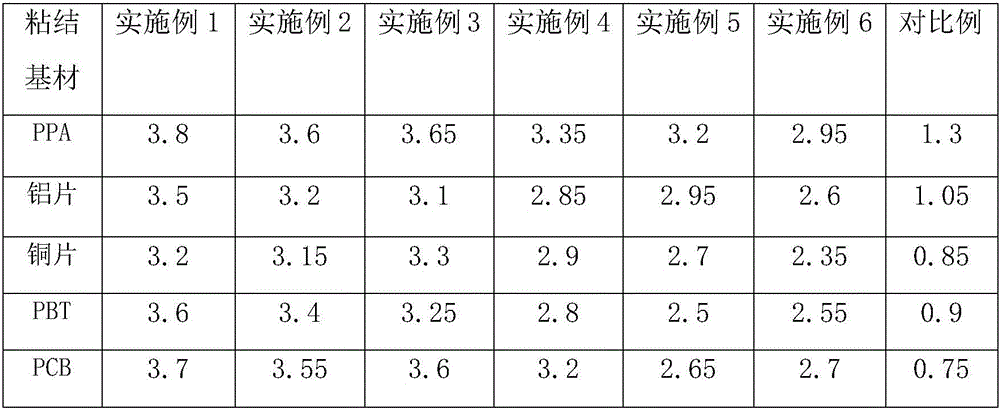

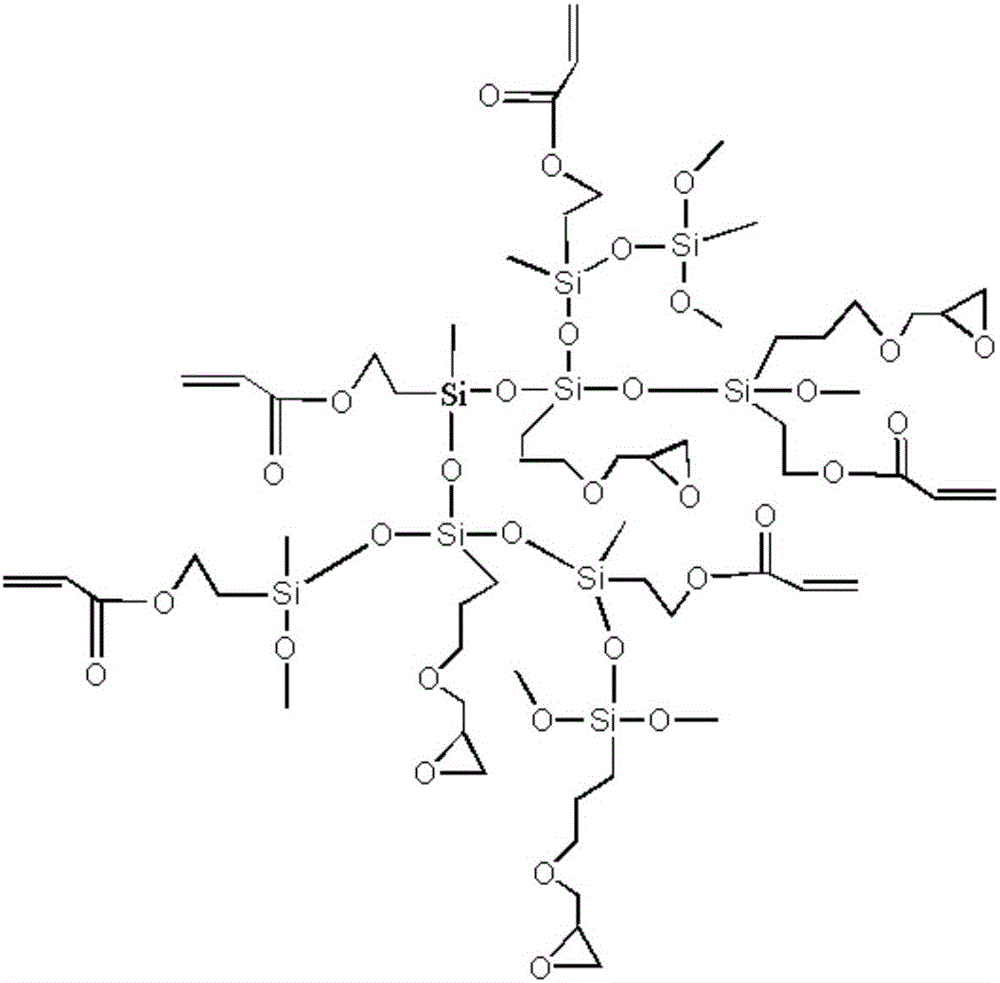

[0020] Add 26.16g 2-acrylic acid 3-(diethoxymethylsilyl) propyl ester (0.12mol), 23.6g gamma-glycidyl etheroxypropyl trimethoxysilane (0.1mol) to 250mL there-necked flask, Stir and mix with a magnet, then raise the temperature to 60°C, add 3.24g deionized water, stir for 30 minutes, then slowly add 0.25g LiOH·H 2 0, after the dropwise addition, react for 5h, then react under vacuum for 1h until the feed liquid does not foam, stop the vacuum, add 1.7g stearic acid, stir and react for 0.5h after adding, stop heating, cool down, and discharge, After the reaction is complete, add 26.15g of n-heptane, wash with water, separate layers, add anhydrous sodium sulfate to dry, filter, put the filtrate in a rotary evaporator, and vacuum remove small molecules at 95°C for 2 hours to obtain a colorless and transparent tackifier.

Embodiment 2

[0022] Add 26.16g 2-acrylic acid 3-(diethoxymethylsilyl) propyl ester (0.12mol), 27.8g gamma-glycidyl etheroxypropyl triethoxysilane (0.1mol) to the 250mL three-necked flask , magnetically stirred and mixed, then heated up to 60°C, added 3.24g deionized water, stirred for 30 minutes, and then slowly added 0.27g LiOH·H to the three-necked flask 2 0, after the dropwise addition, react for 5h, then react for 1h under vacuum conditions, until the feed liquid does not foam, stop the vacuum, add 1.83g stearic acid, stir and react for 0.5h after adding, stop heating, cool down, and discharge, After the reaction is complete, add 26.15g of n-heptane, wash with water, separate layers, add anhydrous sodium sulfate to dry, filter, put the filtrate in a rotary evaporator, and vacuum remove small molecules at 95°C for 2 hours to obtain a colorless and transparent tackifier.

Embodiment 3

[0024] Add 28.16g of 3-trimethoxysilane propyl acrylate (0.12mol) and 22.1g of γ-glycidylpropylmethyldimethoxysilane (0.1mol) to a 250mL three-necked flask, stir and mix with a magnet, and then heat up to 60 ℃, add 3.24g deionized water, stir for 30 minutes, then slowly add 0.25g LiOH·H 2 0, after the dropwise addition, react for 5h, then react under vacuum for 1h until the feed liquid does not foam, stop the vacuum, add 1.7g stearic acid, stir and react for 0.5h after adding, stop heating, cool down, and discharge, After the reaction is complete, add 28.15g of n-heptane, wash with water, separate layers, add anhydrous sodium sulfate to dry, filter, put the filtrate in a rotary evaporator, and vacuum remove small molecules at 95°C for 2 hours to obtain a colorless and transparent tackifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com