Halogen-free flame-retardant and cold-resistant PC material suitable for charging pile charging gun and preparation method thereof

A charging gun and charging pile technology, which is applied in the field of polymer functional composite materials, can solve the problems of insufficient low temperature impact and large amount of addition, and achieve the effects of small impact, small amount of addition and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

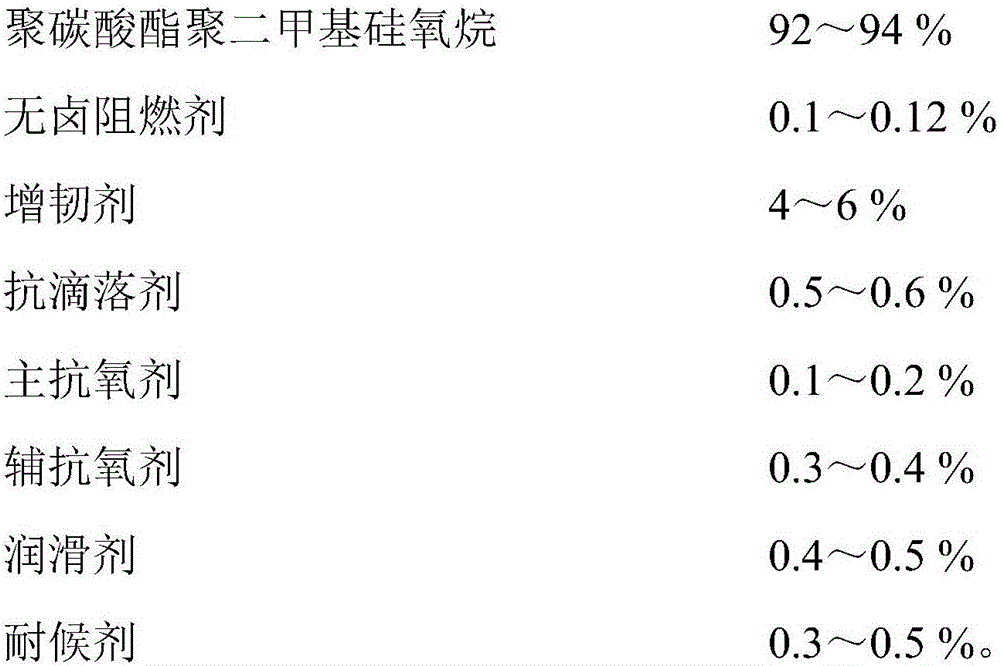

Method used

Image

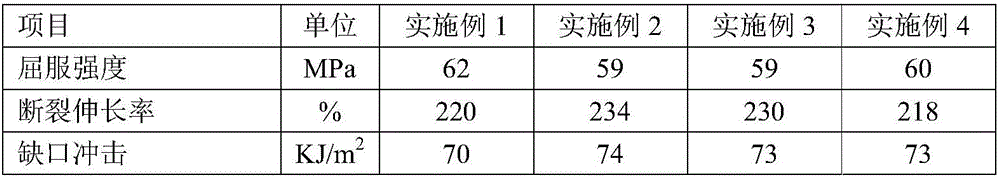

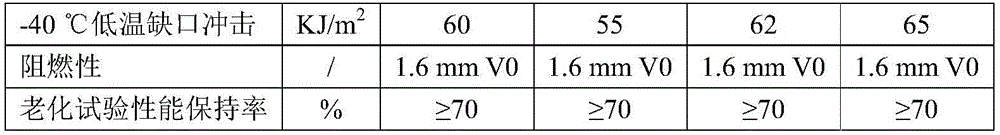

Examples

Embodiment 1

[0040] Weigh the raw materials according to Table 1 and put them into a high-speed mixer, and mix at high and low speeds for 4 minutes at room temperature. The mixed materials are put into the hopper of the twin-screw extruder, melt blended, and extruded and pelletized to obtain a composite material. The processing technology is as follows: Twin-screw extruder temperature in zone one is 220℃, zone two is 260℃, zone three is 260℃, zone four is 260℃, zone five is 250℃, zone six is 240℃, zone seven is 230℃ , The temperature of the eight zones is 230℃, and the temperature of the machine head is 260℃. Screw speed is 400r / min, vacuum degree: 600mmHg, cooling water temperature: 50℃, drying time 2h, drying temperature: 100℃.

Embodiment 2

[0042] Weigh the raw materials according to Table 1 and put them into a high-speed mixer, and mix at high and low speeds for 4 minutes at room temperature. The mixed materials are put into the hopper of the twin-screw extruder, melt blended, and extruded and pelletized to obtain a composite material. The processing technology is as follows: Twin-screw extruder temperature in zone one is 220℃, zone two is 260℃, zone three is 260℃, zone four is 260℃, zone five is 250℃, zone six is 240℃, zone seven is 230℃ , The temperature of the eight zones is 230℃, and the temperature of the machine head is 260℃. Screw speed is 400r / min, vacuum degree: 600mmHg, cooling water temperature: 50℃, drying time 2h, drying temperature: 100℃.

Embodiment 3

[0044] Weigh the raw materials according to Table 1 and put them into a high-speed mixer, and mix at high and low speeds for 4 minutes at room temperature. The mixed materials are put into the hopper of the twin-screw extruder, melt blended, and extruded and pelletized to obtain a composite material. The processing technology is as follows: Twin-screw extruder temperature in zone one is 220℃, zone two is 260℃, zone three is 260℃, zone four is 260℃, zone five is 250℃, zone six is 240℃, zone seven is 230℃ , The temperature of the eight zones is 230℃, and the temperature of the machine head is 260℃. Screw speed is 400r / min, vacuum degree: 600mmHg, cooling water temperature: 50℃, drying time 2h, drying temperature: 100℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com