Preparation method of graphene lubricant

A kind of ene lubricant and graphene technology, applied in the field of preparation of graphene lubricant, can solve the problems of high energy consumption and complicated process, and achieve the effect of simple operation, low wear rate, simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

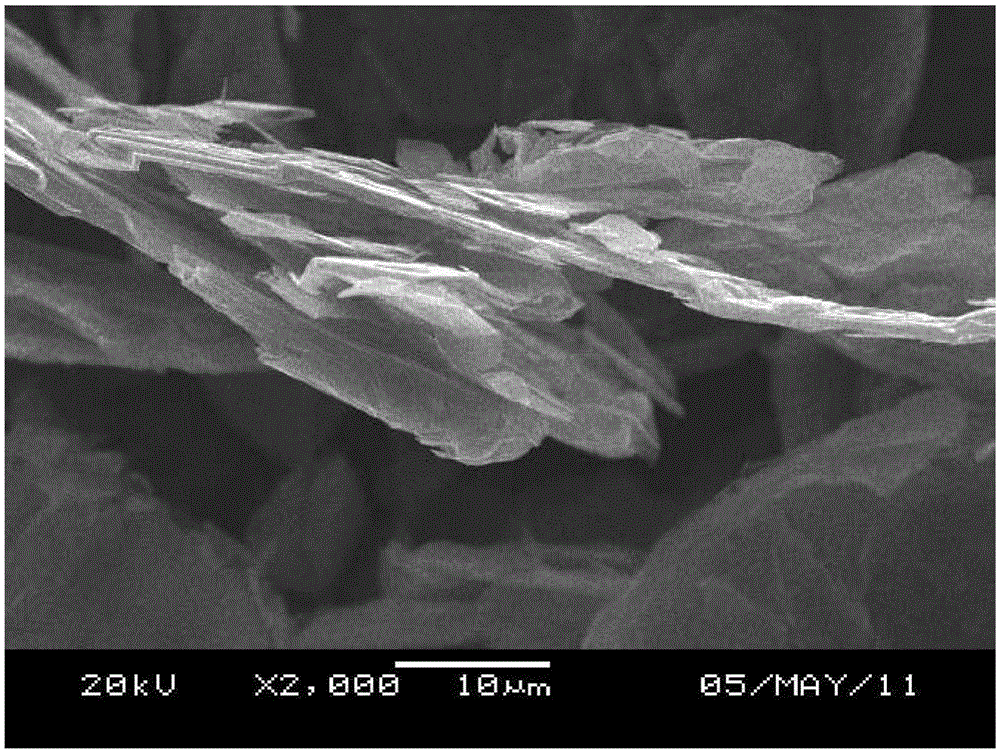

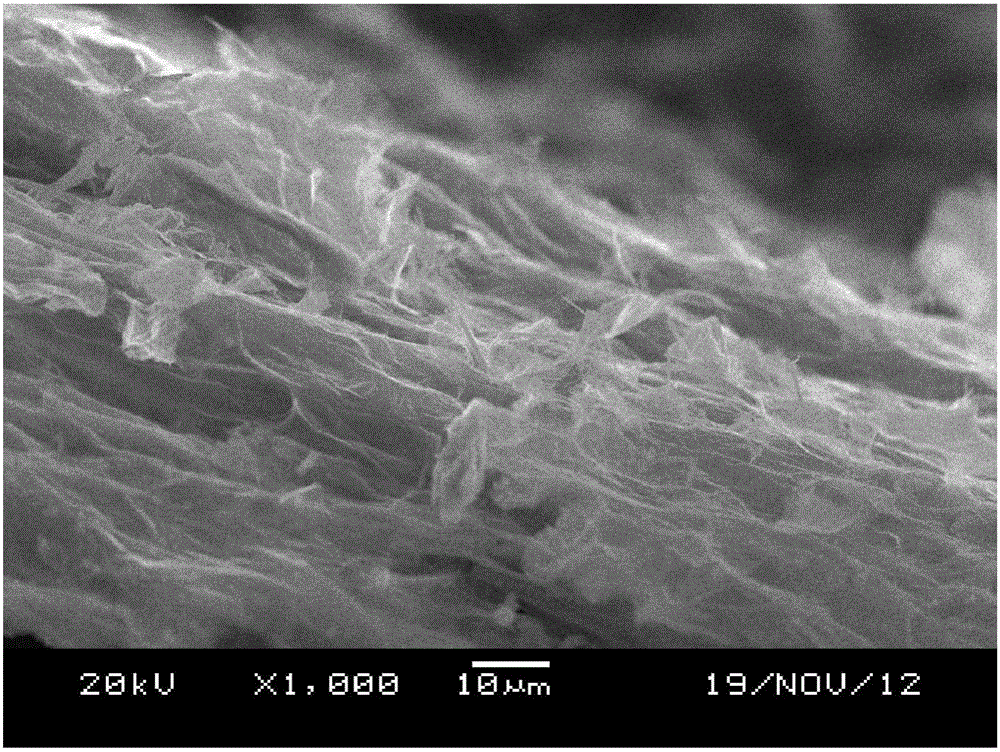

Image

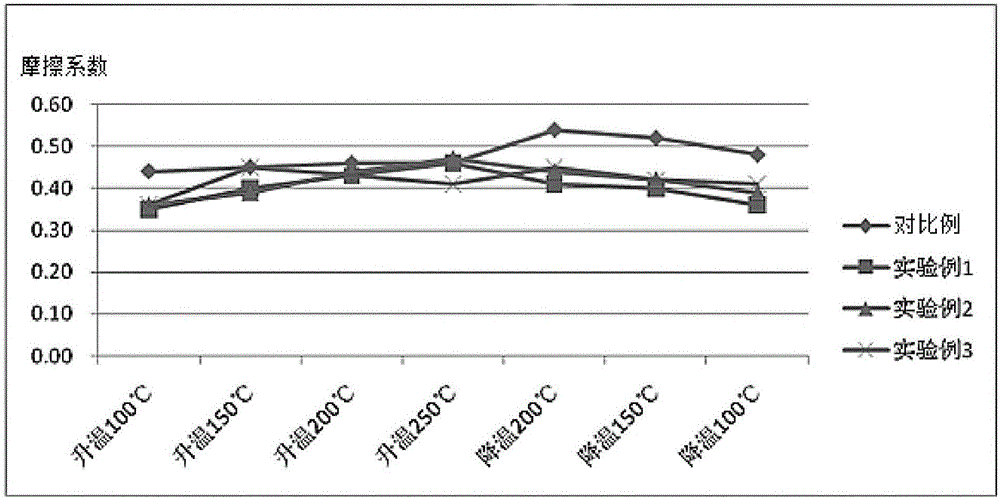

Examples

Embodiment 1

[0036] A kind of preparation of graphene lubricant, preparation step is:

[0037] (1) Preparation of graphene oxide ethanol colloidal suspension: first, using natural flake graphite powder as raw material, graphene oxide was prepared by Hummers oxidation method, first centrifugally cleaned with twice distilled water to neutrality, and then graphene oxide was dispersed in In water ethanol, 50 Hz ultrasonic dispersion was carried out for 20 min; wherein, the amount of absolute ethanol used for 100 mg of graphene oxide was 100 mL.

[0038] (2) Separation of graphene oxide and multilayer graphene oxide: the graphene oxide ethanol solution prepared in step (1) is placed in a high-speed centrifuge for centrifugation, centrifuged at a speed of 3000r / min for 5min, after centrifugation , separating the upper layer solution and the bottom layer precipitate, the upper layer solution is graphene oxide, and the bottom layer precipitate is multilayer graphene oxide.

[0039] (3) Dry multil...

Embodiment 2

[0044] A kind of preparation of graphene lubricant, preparation step is as embodiment 1, but different from embodiment 1 is:

[0045] In step (1), the ultrasonic dispersion power is 80 Hz, and the ultrasonic time is 10 min;

[0046] In step (2), the centrifugal time is 3min, and the centrifugal speed is 5000r / min;

[0047] In step (3), the drying temperature is 60° C., and the drying time is 48 hours;

[0048] In step (4), the mass ratio of multilayer graphene oxide to natural flake graphite is 1%.

Embodiment 3

[0050] A kind of preparation of graphene lubricant, preparation step is as embodiment 1, but different from embodiment 1 is:

[0051] Step (1) The ultrasonic dispersion power is 100Hz, and the ultrasonic time is 30min;

[0052] In step (2), the centrifugation time is 10min, and the centrifugation speed is 10000r / min;

[0053] In step (3), the drying temperature is 80° C., and the drying time is 24 hours;

[0054] Step (4) The mass ratio of multilayer graphene oxide to natural flake graphite is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com