Preparation method of office paper with effect of moisture prevention

A technology of paper and sulfate, applied in the field of papermaking, can solve the problems of paper moisture return, achieve the effects of reducing moisture absorption, high smoothness, and improving machine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

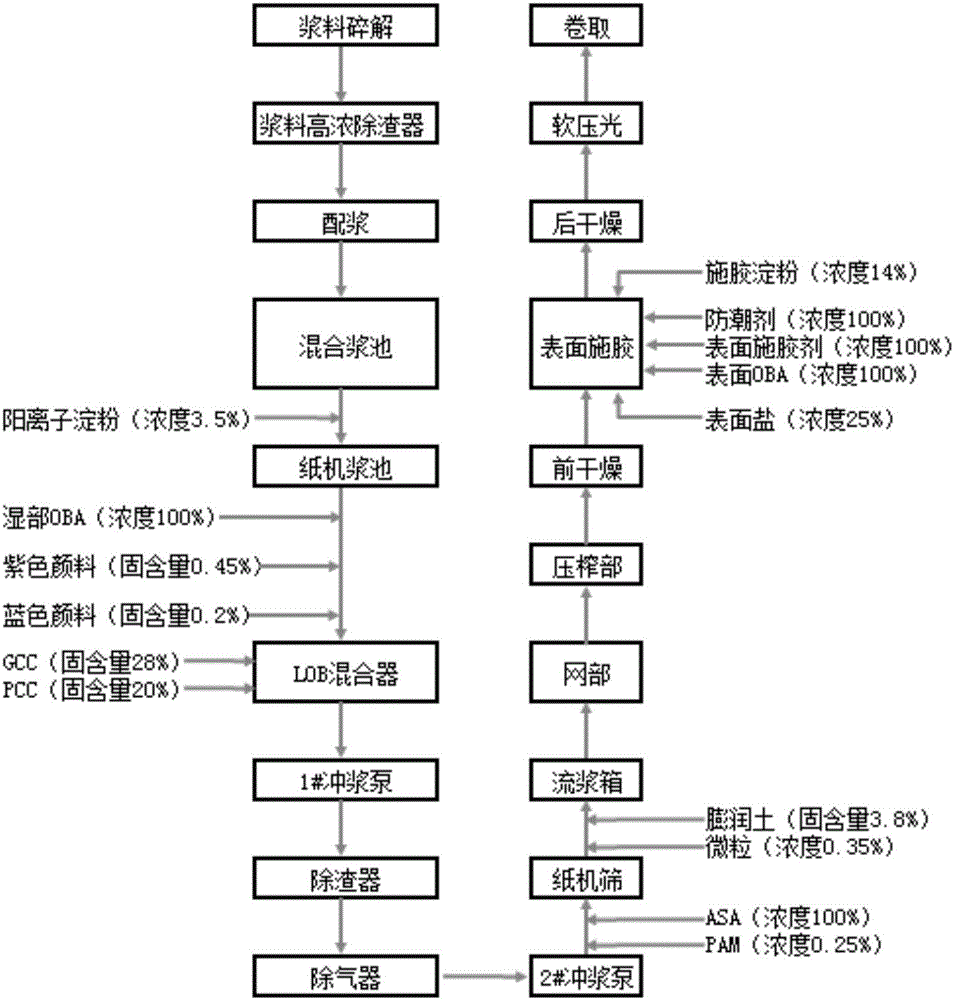

[0026] An embodiment of a preparation method of office paper with moisture-proof effect, as attached figure 1 Shown, described preparation method comprises the following steps:

[0027] (1) Slurry disintegration and slag removal: disintegrate the imported long and short fiber kraft wood pulp and chemical mechanical pulp at a concentration of 5% by mass respectively, When the mass percentage concentration of the slurry is 4%, it will be treated by a high-concentration slag remover to remove heavy impurities in the slurry;

[0028] (2) beating: the pulp after step (1) is crushed is beaten, the freeness of short fiber kraft wood pulp is controlled at 300CFS after beating, and the freeness of short fiber kraft wood pulp is controlled at about 280CFS;

[0029] (3) Pulp preparation and pulp purification: the long fiber kraft wood pulp and short fiber kraft wood pulp and chemical mechanical pulp after beating are divided into long fiber kraft wood pulp: short fiber kraft wood pulp: ...

Embodiment 2

[0039] An embodiment of a preparation method of office paper with moisture-proof effect, as attached figure 1 Shown, described preparation method comprises the following steps:

[0040] (1) Slurry disintegration and slag removal: disintegrate the imported high-strength, high-whiteness long and short fiber sulfate and chemical mechanical pulp at a concentration of 5% by mass, and then disintegrate the long and short fiber sulfate When the mass percentage concentration of wood pulp and chemical mechanical pulp is 4%, it will be treated by high-consistency slag remover to remove heavy impurities in the pulp;

[0041] (2) beating: the pulp after step (1) is crushed is beaten, the freeness of long fiber kraft wood pulp is controlled at 400CFS after beating, and the freeness of short fiber kraft wood pulp is controlled at about 380CFS;

[0042](3) Pulp preparation and pulp purification: the long fiber kraft wood pulp and short fiber kraft wood pulp and chemical mechanical pulp afte...

Embodiment 3

[0052] An embodiment of a preparation method of office paper with moisture-proof effect, as attached figure 1 Shown, described preparation method comprises the following steps:

[0053] (1) Slurry disintegration and slag removal: disintegrate the imported high-strength, high-whiteness long and short fiber sulfate and chemical mechanical pulp at a concentration of 5% by mass, and then disintegrate the long and short fiber sulfate When the mass percentage concentration is 4%, it will be treated by a high-concentration slag remover to remove heavy impurities in the slurry;

[0054] (2) beating: the pulp after step (1) is crushed is beaten, the freeness of long-fiber kraft wood pulp is controlled at 350CFS after beating, and the freeness of short-fiber kraft wood pulp is controlled at about 330CFS;

[0055] (3) Pulp preparation and pulp purification: the long fiber sulfate and chemical mechanical pulp after beating are divided into long fiber sulfate fiber wood pulp: short fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com