One-dimensional antimony sulfide-carbon composite material and preparation method and application thereof

A carbon composite material and a composite material technology, applied to one-dimensional antimony sulfide-carbon composite materials, in the field of its preparation, can solve the problems of carbon nanotube composite difficulty, poor cycle stability, low specific capacity, etc., and achieve uniform morphology and performance. Good, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

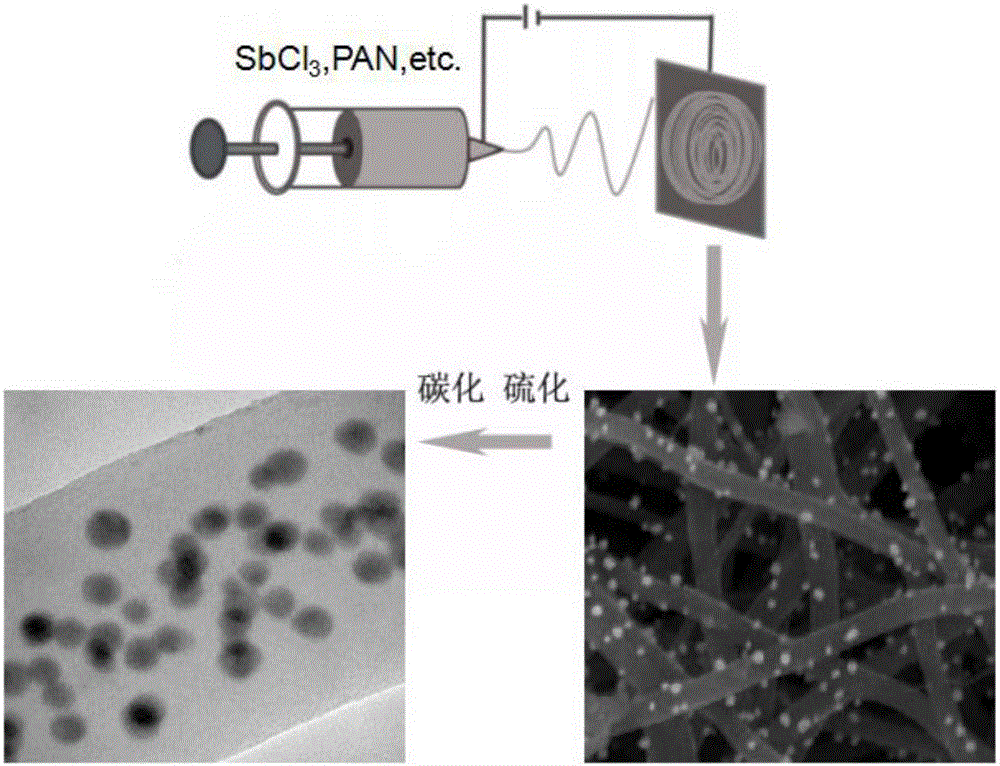

[0031] The preparation method of the one-dimensional antimony sulfide-carbon nanowire composite material proposed by the present invention comprises the following steps:

[0032] (1) Antimony chloride, polyacrylonitrile, and N,N-dimethylformamide are uniformly mixed in a mass ratio of 0.07-0.11:0.07-0.11:1 to prepare an antimony salt precursor spinning solution;

[0033] (2) Spinning the precursor spinning solution obtained in step (1) under high pressure to obtain a precursor one-dimensional nanowire; wherein the spinning voltage is 18-22KV, preferably 20KV, and the spinning bolus rate is 0.2- 1.0mm / min, preferably 0.6mm / min;

[0034] (3) Calcining the one-dimensional nanowire obtained in step (2) at a high temperature in a hydrogen / argon atmosphere, the volume ratio of the hydrogen / argon gas mixture is 10:90, and obtaining a one-dimensional antimony-doped carbon nanowire after cooling; The calcination temperature is 550-750°C, and the calcination time is 6-10h;

[0035] (4...

Embodiment 1

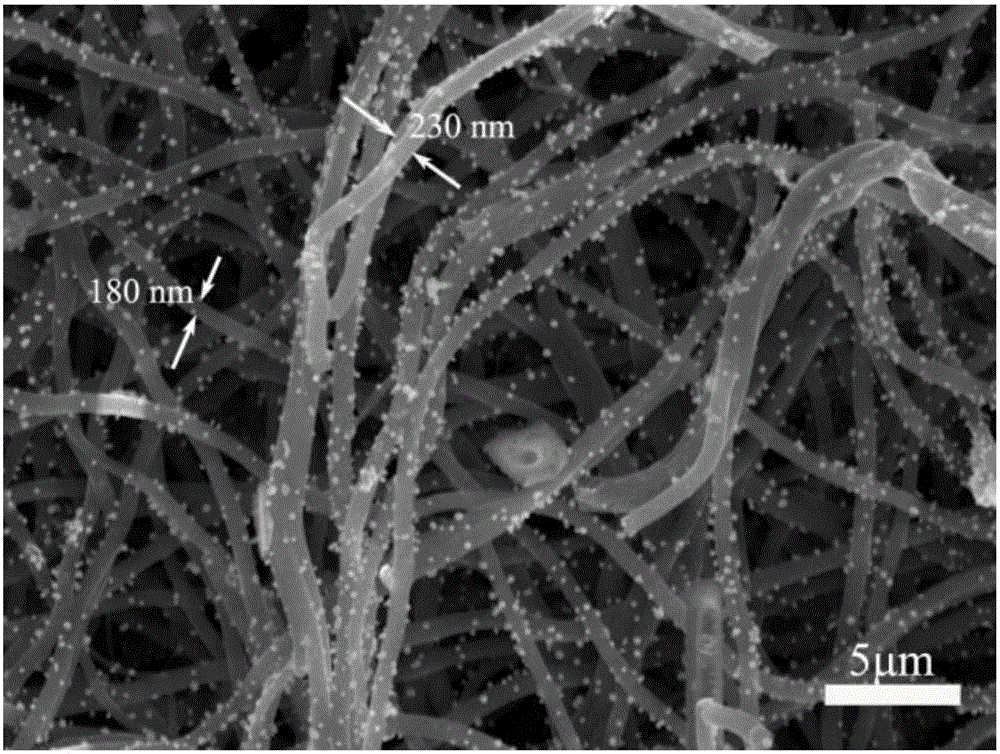

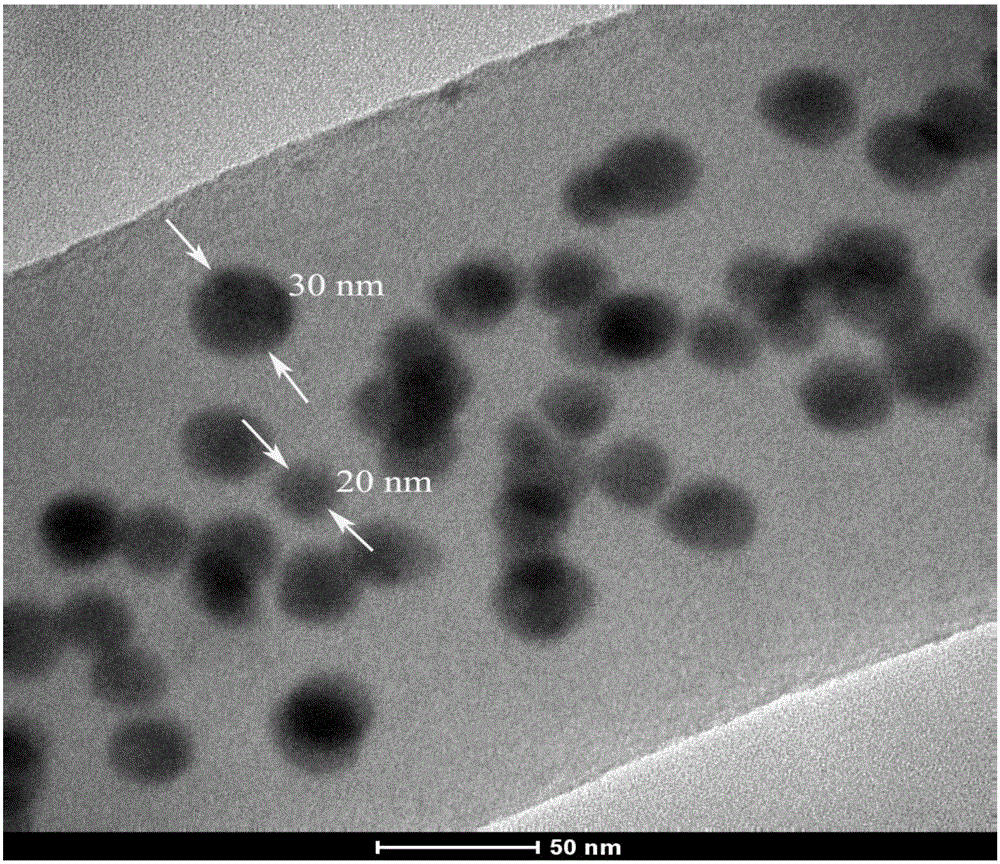

[0041] a kind of like figure 1 The preparation method of the shown one-dimensional antimony sulfide-carbon nanowire composite material comprises the following steps:

[0042] (1) Preparation of spinning precursor solution: Weigh antimony chloride, PAN and DMF at a mass ratio of 0.09:0.09:1, stir for 24 hours, and mix them uniformly to obtain a spinning precursor solution.

[0043] (2) Preparation of nanowire precursor: the spinning precursor solution prepared in the above step (1) was spun in an electrospinning device with a voltage of 20KV and a bolus rate of 0.6mm / min.

[0044] (3) Preparation of one-dimensional Sb / C nanowire composite material: the nanowire precursor obtained in the above (2) is placed in a tube furnace for calcination (10:90, Vol), and the calcination temperature is 650°C, the calcination time is 6h, and the heating rate is 5°C / min.

[0045] (4) Preparation of one-dimensional antimony sulfide-carbon nanowire composite material: Sulfurize the structurally...

Embodiment 2

[0048] a kind of like figure 1 The preparation method of the shown one-dimensional antimony sulfide-carbon nanowire composite material comprises the following steps:

[0049] (1) Preparation of spinning precursor solution: Weigh antimony chloride, PAN and DMF in a mass ratio of 0.07:0.11:1, stir for 24 hours, and mix them uniformly to obtain a spinning precursor solution.

[0050] (2) Preparation of nanowire precursor: the spinning precursor solution prepared in the above step (1) was spun in an electrospinning device with a voltage of 18KV and a bolus rate of 0.2mm / min.

[0051] (3) Preparation of one-dimensional Sb / C nanowire composite material: the nanowire precursor obtained in the above (2) is placed in a tube furnace for calcination (10:90, Vol), and the calcination temperature is 750°C, calcination time 10h, heating rate 10°C / min, to obtain a one-dimensional Sb / C nanowire composite material.

[0052] (4) Preparation of one-dimensional antimony sulfide-carbon nanowire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com