Chitosan-based plant leaf surface water evaporation retardant and preparation method thereof

An evaporation inhibitor, chitosan technology, applied in the fields of botany equipment and methods, plant preservation, application, etc., can solve problems such as inability to accurately judge the spraying process, excessive pesticide residues in plants and soil, and easy occurrence of diseases and insect pests. Good biological safety and chemical stability, prolonging the effect of pesticide action time, and enhancing the effect of pesticide action force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

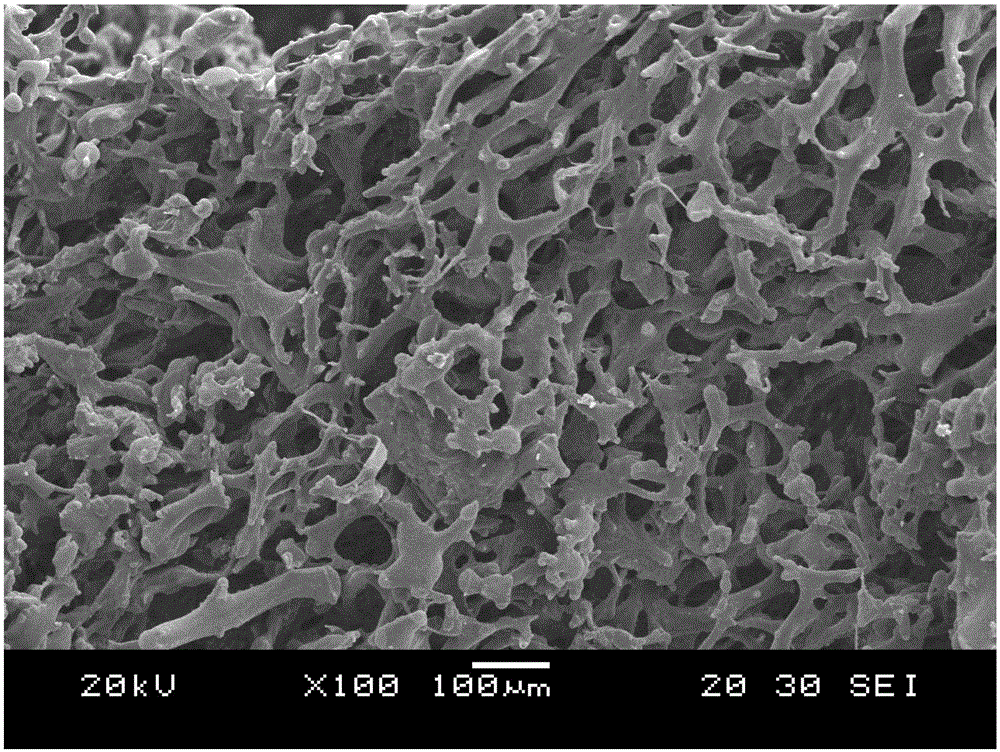

Image

Examples

Embodiment 1

[0039] (1) 5 g of chitosan was added to 50 g of 30% sodium hydroxide solution at room temperature, alkalized for 12 hours, and 30 mL of absolute ethanol was added to obtain a 7.7% (w / v) chitosan solution.

[0040] (2) Dissolve 5g of chloroacetic acid in 10mL of absolute ethanol, fully dissolve to obtain a 50% (w / v) ethanol solution of chloroacetic acid, add it dropwise to the chitosan solution under stirring, and react for 2 hours at room temperature , continue the reaction at 50°C for 1 hour.

[0041] (3) After cooling, adjust the pH of the solution with glacial acetic acid to be 6.5, and then filter under reduced pressure after cooling, and the product is washed with 75% aqueous ethanol until there is no Cl in the filtrate. - residual. The product was dried in an oven to obtain carboxymethyl chitosan.

[0042] (4) With stirring at room temperature, add 1 g of carboxymethyl chitosan to 50 mL of 0.1 mol·L -1 Slowly dissolve in the hydrochloric acid solution, continue to sti...

Embodiment 2

[0048] (1) 5 g of chitosan was added to 50 g of 40% sodium hydroxide solution at room temperature, alkalized for 14 hours, and 20 mL of absolute ethanol was added to obtain a 10% (w / v) chitosan solution.

[0049] (2) Dissolve 5g of chloroacetic acid in 10mL of absolute ethanol, fully dissolve to obtain a concentration of 50% (w / v) chloroacetic acid ethanol solution, add it dropwise to the chitosan solution under stirring, and react for 3 hours at room temperature , continue the reaction at 60°C for 2 hours.

[0050] (3) After cooling, adjust the pH of the solution with glacial acetic acid to be 7, and filter under reduced pressure after cooling, and the product is washed with 80% aqueous ethanol until there is no Cl in the filtrate. - residual. The product was dried in an oven to obtain carboxymethyl chitosan.

[0051] (4) With stirring at room temperature, add 1 g of carboxymethyl chitosan to 40 mL of 0.1 mol·L -1Slowly dissolve in the hydrochloric acid solution, continue ...

Embodiment 3

[0057] (1) 5 g of chitosan was added to 50 g of 40% sodium hydroxide solution at room temperature, alkalized for 16 hours, and 30 mL of absolute ethanol was added to obtain a 8.3% (w / v) chitosan solution.

[0058] (2) Dissolve 6.5g of chloroacetic acid in 10mL of absolute ethanol, fully dissolve to obtain a concentration of 65% (w / v) chloroacetic acid ethanol solution, add drop by drop in the chitosan solution under stirring, react at room temperature for 4 Hours, the reaction was continued at 65°C for 2 hours.

[0059] (3) After cooling, adjust the pH of the solution with glacial acetic acid to be 7, and then filter under reduced pressure after cooling, and the product is washed with 75% aqueous ethanol until there is no Cl in the filtrate. - residual. The product was dried in an oven to obtain carboxymethyl chitosan.

[0060] (4) With stirring at room temperature, add 1 g of carboxymethyl chitosan to 50 mL of 0.1 mol·L -1 Slowly dissolved in a hydrochloric acid solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com