Fermented milk composition for ice cream, fermented milk for ice cream and their preparation methods

A technology for fermented milk and ice cream, applied in the field of fermented milk, can solve the problems of limited protein and acidity, which cannot be called fermented milk ice cream, etc., and achieve the effect of reasonable slurry viscosity and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In another specific embodiment, a method for preparing fermented milk for ice cream is provided, comprising the following steps: mixing the above-mentioned fermented milk composition for ice cream, concentrating to 100 parts, homogenizing, and sterilizing to obtain concentrated milk; Add starter to the cooled concentrated milk to make the live bacteria content in the concentrated milk 1×10 6 ~1×10 9 cfu / mL to obtain fermented milk. The live bacteria mentioned above only refer to the live bacteria brought into the concentrated milk by adding a starter.

[0044] Since the fermented milk composition for ice cream has the above beneficial effects, the method for preparing fermented milk for ice cream using the fermented milk composition for ice cream as a raw material also has corresponding beneficial effects, which will not be repeated here.

[0045] In addition, through the optimization of process parameters, the appearance, color, texture, taste, flavor, and sour-sweet...

Embodiment 1

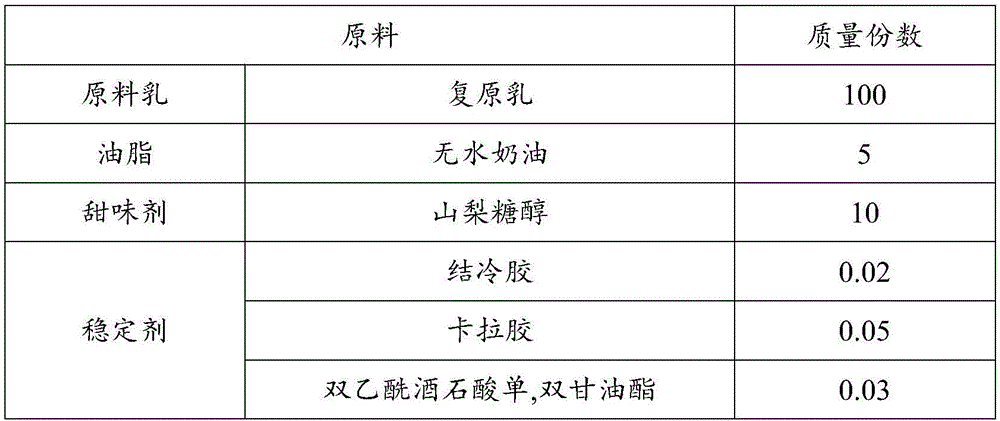

[0059] 1. Proportion

[0060] Table 1

[0061]

[0062]

[0063] 2. Method

[0064] (1) Mix the raw milk, oil, sweetener and stabilizer according to the ratio in Table 1 at 60°C for 10 minutes, concentrate to 100 parts, 15Mpa 54°C first-grade homogeneous, 90°C for 5 minutes to obtain concentrated milk ;

[0065] (2) Cool the concentrated milk to 37°C, add the starter according to the ratio in Table 1, and ferment at 37°C. After 10 hours, the acidity reaches 70°T, and the fermentation is stopped to obtain fermented milk;

[0066] (3) The fermented milk is turned over and thinned through the back pressure valve, cooled to 15°C, filled, and stored and transported at 9°C after filling.

[0067] After testing, after 21 days of preservation at 9°C, the number of lactic acid bacteria was 4.8×10 7 , mold, yeast, Escherichia coli, and pathogenic bacteria were not detected; it can pass through the ice cream machine smoothly, and the ice cream made is used for taste evaluation....

Embodiment 2

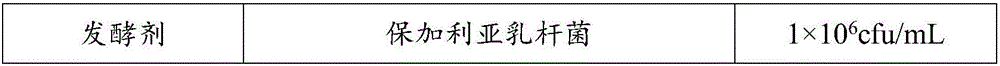

[0069] 1. Proportion

[0070] Table 2

[0071]

[0072]

[0073] 2. Method

[0074] (1) Circulate raw milk, oil, sweetener, stabilizer and fermented milk additives according to the ratio in Table 2 through the batching system at 62°C for 16 minutes, concentrate to 100 parts, 16Mpa 55°C first-grade homogeneous, 91°C Sterilize for 5 minutes to obtain concentrated milk;

[0075] (2) Cool the concentrated milk to 38°C, add starter and probiotics according to the ratio in Table 2, and ferment at 38°C, after 9 hours the acidity reaches 71°T, stop the fermentation to obtain fermented milk;

[0076] (3) The fermented milk is turned over and thinned by a smoother, cooled to 16°C, filled, and stored and transported at 7°C after filling.

[0077] After testing, 21 days after placement, the number of lactic acid bacteria was 5.9×10 7 , mold, yeast, Escherichia coli, and pathogenic bacteria were not detected; it can pass through the ice cream machine smoothly, and the ice cream m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com