Preparation method for antibacterial hemostatic microspheres based on cellulose

A carboxymethyl cellulose and cellulose technology, applied in the field of functional polymer materials, can solve the problems of poor biocompatibility, hemostatic microspheres do not have antibacterial properties, etc., achieve good hemostasis performance, improve cross-linking effect and stability , the effect of promoting hydrophobic association

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

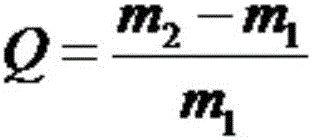

Method used

Image

Examples

Embodiment 1

[0022] Example 1: 0.5 g of carboxymethyl cellulose grafted polylactic acid was dissolved in 99.5 g of ethanol to obtain solution A. Dissolve 0.5g of sodium alginate in 49.5g of water to obtain solution B, mix the above solutions A and B, add 0.075g of emulsifier Tween-80, and 1.5g of tea tree oil, heat and stir at 50°C for 3h . After the microspheres were centrifuged, washed with DMSO, filtered and dried, the microsphere product was obtained.

Embodiment 2

[0023] Example 2: 0.4 g of carboxymethyl cellulose grafted polylactic acid was dissolved in 79.6 g of ethanol to obtain solution A. Dissolve 0.7g of potassium alginate in 69.3g of water to obtain solution B, mix the above solutions A and B, add 0.075g of emulsifier Tween-80, and 1.5g of tea tree oil, heat and stir at 50°C for 3h . After the microspheres were centrifuged, washed with DMSO, filtered and dried, the microsphere product was obtained.

Embodiment 3

[0024] Example 3: 2 g of carboxymethyl cellulose grafted poly(tert-butyl acrylate) was dissolved in 98 g of acetone to obtain solution A. Dissolve 2g of sodium alginate in 18g of water to obtain solution B, mix the above solutions A and B, add 0.12g of emulsifier AEO-9, and 1.8g of tea tree oil, heat and stir at 70°C for 1h. After the microspheres were centrifuged, washed with DMAc, filtered and dried, the microsphere product was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com