Full-automatic purification device for laboratory acid mist exhaust gas

A purification device, fully automatic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

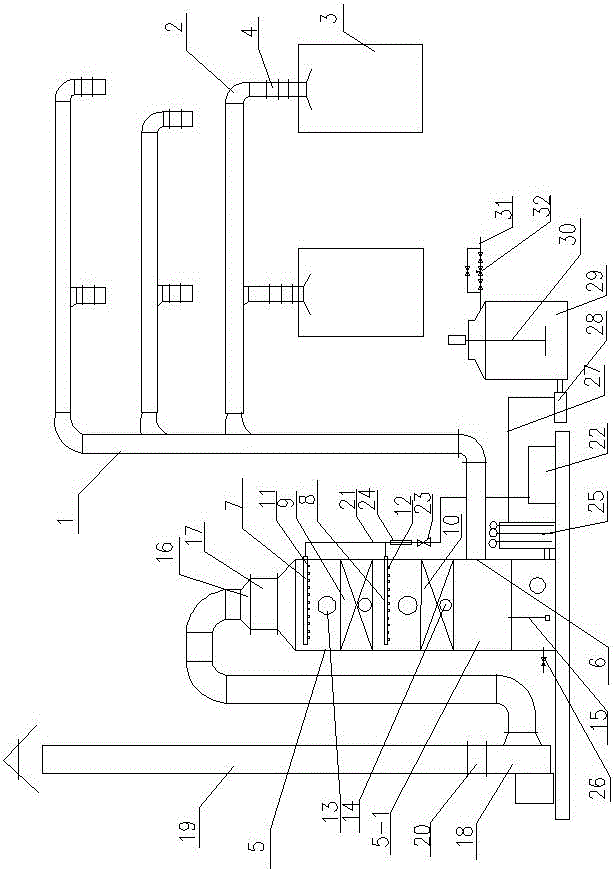

[0020] like figure 1 As shown, the present invention includes a main waste gas collection pipe 1, three waste gas collection branch pipes 2, and the output end of each waste gas collection branch pipe 2 is respectively connected to the waste gas collection main pipe 1; There are two fume hoods 3, and electric regulating air valves 4 are respectively arranged between each fume hood 3 and the exhaust gas collection branch pipe 2; the output end of the exhaust gas collection main pipe 1 is connected to the air inlet 6 at the lower part of the purification tower 5.

[0021] The purification tower 5 includes a shell 5-1, an upper spray pipe 7, a lower spray pipe 8, a first Pall ring packing layer 9, and a second Pall ring packing layer 10; the upper spray pipe 7, the first The Pall ring packing layer 9, the lower spray pipe 8 and the second Pall ring packing layer 10 are sequentially arranged from top to bottom along the height direction of the casing 5-1; A lower spiral nozzle 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com