Silver powder with flower-shaped microstructure and preparation method thereof and electric conducting ink

A technology of microstructure and conductive ink, which is applied in the direction of ink, household utensils, nanotechnology, etc., can solve the problems of non-conductive printing, printing accuracy, insufficient curing of conductive ink, and prolonged curing time, etc., and achieve fine feature size , uniform size, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] This specific embodiment provides a kind of preparation method of silver powder, comprises the following steps:

[0021] S1, respectively prepare a precursor solution, a first reducing agent solution, a surfactant solution, a silver salt solution and a second reducing agent solution.

[0022] Wherein, the molar concentration ratio of the precursor salt solution, the first reducing agent solution, the surface active solution, the silver salt solution and the second reducing agent solution is 1:0.1-10:0.05-50:0.1-5:0.1-10. Anions in the precursor solution can form complex precursors with silver ions. The first reducing agent solution is a weak reducing agent solution, such as a mixture of one or more of formaldehyde, acetaldehyde, citric acid, and ascorbic acid. The second reducing agent solution is selected from a reducing agent solution with stronger reducibility than the first reducing agent solution, such as formaldehyde, acetaldehyde, ascorbic acid, sodium borohydri...

Embodiment 1

[0038] The preparation method of silver powder in the present embodiment comprises the following steps: (1) getting 1L concentration respectively is the sodium citrate solution of 0.24mol / L, 1L concentration is the formaldehyde solution (the first reductant solution) of 37wt% and 2L concentration is 1wt% % Tween-80 solution (sorbitan ester surfactant), and add in the reaction vessel and stir; In the above-mentioned reaction vessel, stir with stirring speed 200 revs per minute, make silver salt precursor solution after reacting for 30 minutes; (3) in the silver salt precursor solution of step (2) gained, drop speed 0.5L / Add 1 L of sodium borohydride solution (the second reducing agent solution) with a concentration of 0.24 mol / L in min, stir at a stirring speed of 500 rpm, adjust the pH to 10.0, continue the reaction at 25° C. for 30 minutes, and then stop the reaction; ( 4) The precipitate is filtered, washed and dried in vacuum to obtain silver powder.

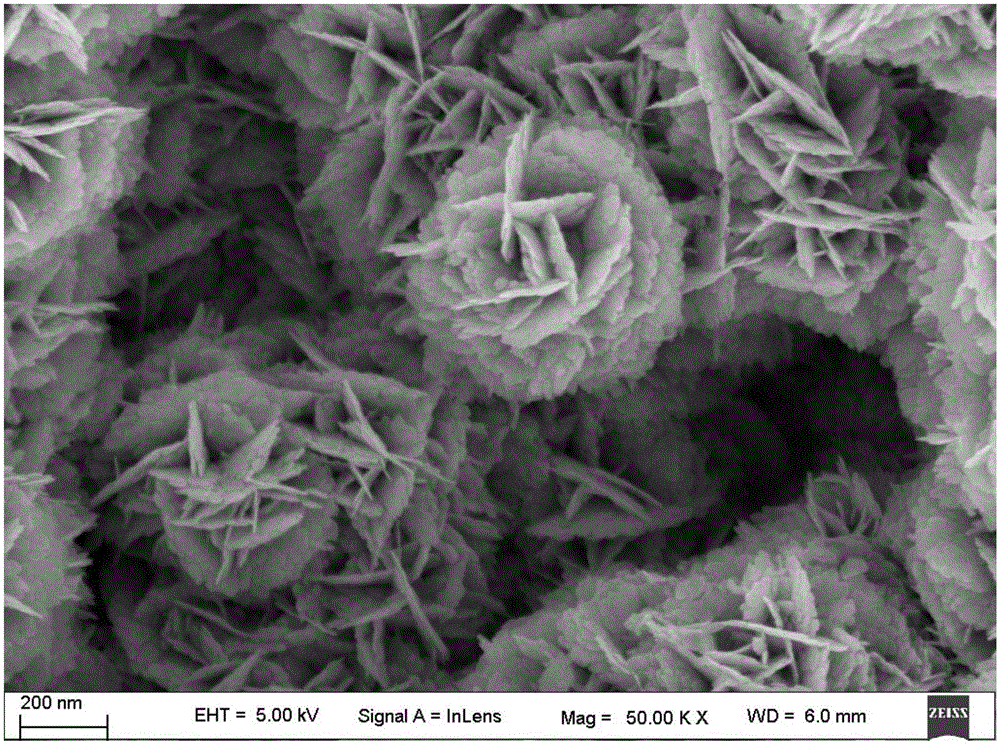

[0039] Such as fig...

Embodiment 2

[0042] The preparation method of silver powder in the present embodiment comprises the following steps: (1) get 1L concentration respectively and be the sodium citrate solution of 0.48mol / L, 1L concentration be the ascorbic acid solution (the first reducing agent solution) of 0.48mol / L and 1L 1wt % Tridaton X-100 solution (polyoxyethylene ether surfactant solution), and add in the reaction vessel and stir evenly; Drop rate is added in the above-mentioned reaction vessel, stirs with stirring speed 200 revs per minute, makes silver salt precursor solution after reacting for 30 minutes; Add 1 L of 0.48 mol / L hydrazine hydrate solution (the second reducing agent solution) at 0.3 L / min, stir at a stirring speed of 350 rpm, adjust the pH to 10.0, and continue the reaction at 0°C for 30 minutes before stopping the reaction; (4) The precipitate is filtered, washed and dried in vacuum to obtain silver powder.

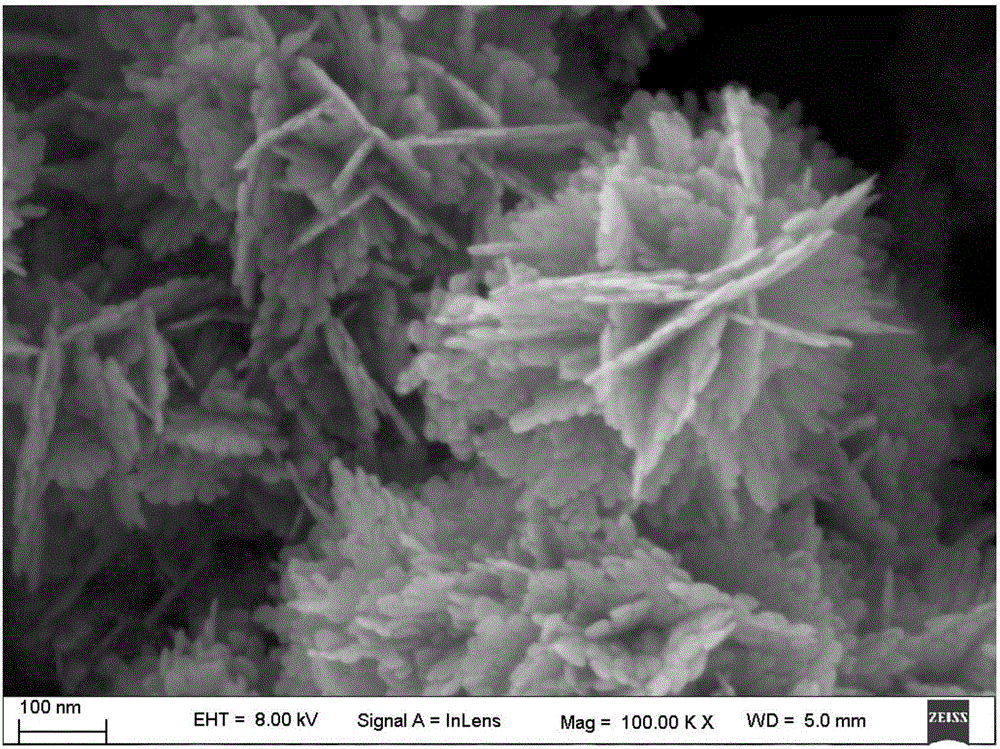

[0043] Such as figure 2 Shown is the SEM picture of the prepared silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com