Molecular sieve crystallization mother liquor treatment method

A treatment method and technology for crystallization mother liquor, applied in molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, distillation in boiler/distillate, etc. The effect of reducing labor intensity, avoiding leakage of harmful substances, and solving processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

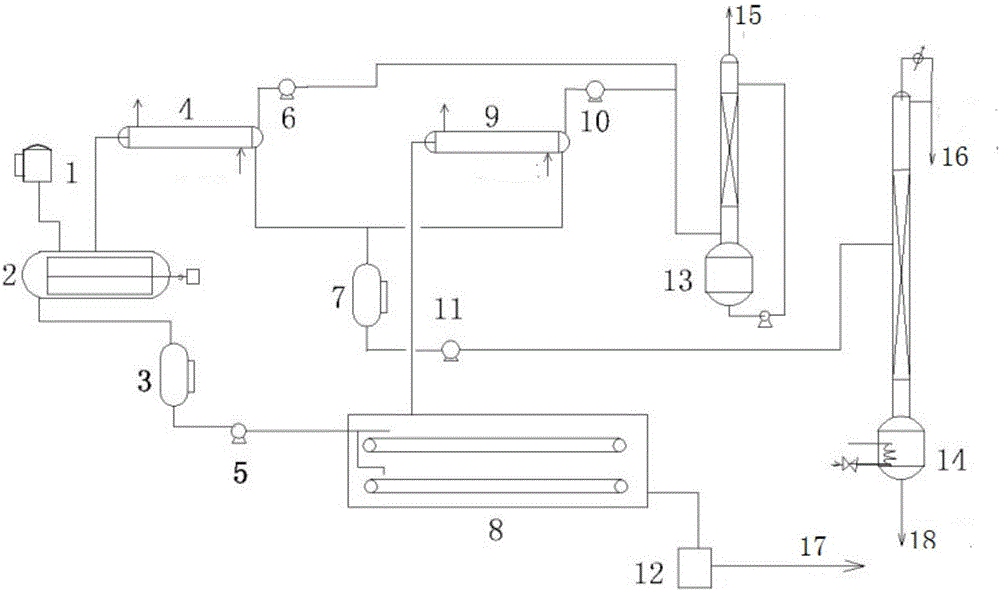

[0035] use figure 1 process shown. The crystallization mother liquor used is the filtrate obtained by filtration and separation after the synthesis of SAPO-34 molecular sieve. The triethylamine content of the template agent is 7.6%, and the total solid content of the mother liquor is about 9%. Set of steam heating, the working temperature is 39 ℃.

[0036] When starting to run, the vacuum pump will evacuate the decompression dehydration device system. After the vacuum reaches -0.091MPa, the liquid inlet valve will automatically open the liquid inlet, and the liquid inlet volume will be 250L / time; after the liquid inlet is completed, it will be heated with steam, and the steam pressure will be 0.17MPa, and start at the same time In-tank mixer.

[0037] The steam evaporated from the mother liquor is simply filtered by the aerosol dust collector and then enters the shell and tube condenser to condense to form a liquid. The condensate automatically enters the waste water storage...

Embodiment 2

[0043] According to the conditions and steps described in Example 1, the vacuum dehydration device obtains residues with a water content of 50-51%, and enters the vacuum belt dryer system for drying. Only the temperature of the heating zone is changed: the first zone is 130 ° C, the second Zone 100°C, third zone 40°C, other conditions are the same as in Example 1. The moisture content of the obtained discharged solid powder was 1.57%.

Embodiment 3

[0045] According to the conditions and steps described in Example 1, the vacuum dehydration device obtains a residue with a water content of 50-51%, and enters the vacuum belt dryer system for drying, only changing the heating temperature: the first zone 160 ° C, the second zone 160°C, 40°C in the third zone, other conditions are the same as in Example 1. The moisture content of the obtained discharged solid powder was 0.38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com