Method for intensively inducing aerobic sludge granulation by means of humic acid

An aerobic sludge and humic acid technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of lack of humic acid, etc., and achieve the promotion of microbial growth and sedimentation performance Good, the effect of increasing the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

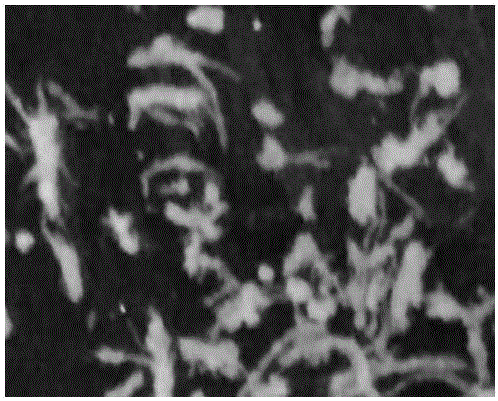

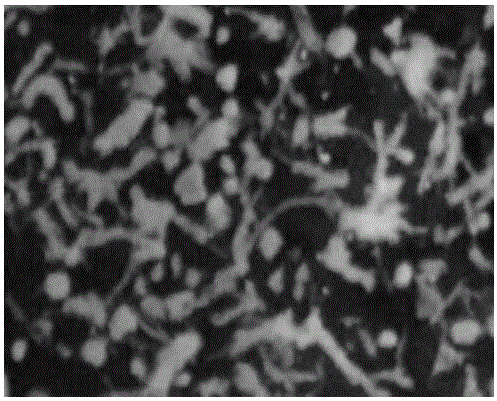

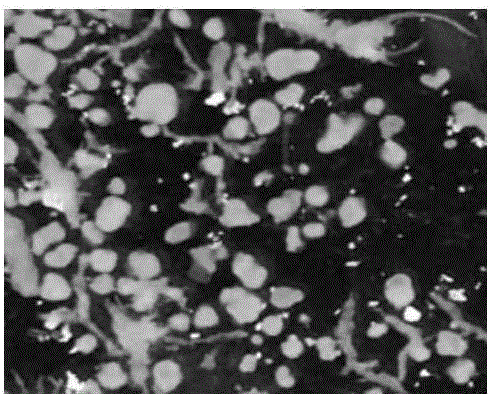

Image

Examples

Embodiment 1

[0037] A kind of humic acid strengthens the method for inducing aerobic sludge granulation, and concrete steps are as follows,

[0038] 1. Take the flocculent activated sludge from the secondary sedimentation tank of the sewage treatment plant as the inoculation sludge, and after continuous aeration for 25 hours, put it into the sequencing batch (SBR) reactor, and the amount of activated sludge added is 10% of the volume of the SBR reactor , The inoculum concentration of activated sludge in the reactor is 1000mg / L.

[0039] 2. In order to ensure the formation of aerobic granular sludge, the influent is artificially synthesized to simulate domestic sewage, mainly using sodium acetate as the carbon source, ammonium chloride as the nitrogen source, potassium dihydrogen phosphate as the phosphorus source, and sodium bicarbonate to adjust pH, keep the pH value of the system at 7-8, and carry out granulation culture on the inoculated sludge in the SBR reactor; at the same time, in o...

Embodiment 2

[0043] A kind of humic acid strengthens the method for inducing aerobic sludge granulation, and concrete steps are as follows,

[0044] 1. Use the flocculent activated sludge from the secondary sedimentation tank of the sewage treatment plant as the inoculation sludge, after continuous aeration for 28 hours, put it into the sequencing batch (SBR) reactor, and the amount of activated sludge added is 20% of the volume of the SBR reactor , The inoculum concentration of activated sludge in the reactor is 1900mg / L.

[0045] 2. In order to ensure the formation of aerobic granular sludge, the influent is artificially synthesized to simulate domestic sewage, mainly using sodium acetate as the carbon source, ammonium chloride as the nitrogen source, potassium dihydrogen phosphate as the phosphorus source, and sodium bicarbonate to adjust pH, keep the pH value of the system at 7-8, and carry out granulation culture on the inoculated sludge in the SBR reactor; at the same time, in order ...

Embodiment 3

[0049] A kind of humic acid strengthens the method for inducing aerobic sludge granulation, and concrete steps are as follows,

[0050] 1. Take the flocculent activated sludge from the secondary sedimentation tank of the sewage treatment plant as the inoculation sludge, after continuous aeration for 30 hours, put it into the sequencing batch (SBR) reactor, and the amount of activated sludge added is 25% of the volume of the SBR reactor , The inoculum concentration of activated sludge in the reactor is 2400mg / L.

[0051] 2. In order to ensure the formation of aerobic granular sludge, the influent is artificially synthesized to simulate domestic sewage, mainly using sodium acetate as the carbon source, ammonium chloride as the nitrogen source, potassium dihydrogen phosphate as the phosphorus source, and sodium bicarbonate to adjust pH, keep the pH value of the system at 7-8, and carry out granulation culture on the inoculated sludge in the SBR reactor; at the same time, in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com