Viscosity reduction type polycarboxylate superplasticizer used for high-strength concrete

A technology of viscous polycarboxylic acid and high-strength concrete, which is applied in the field of building admixtures, and can solve the problems that do not involve viscosity-reducing polycarboxylate water-reducing agent and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

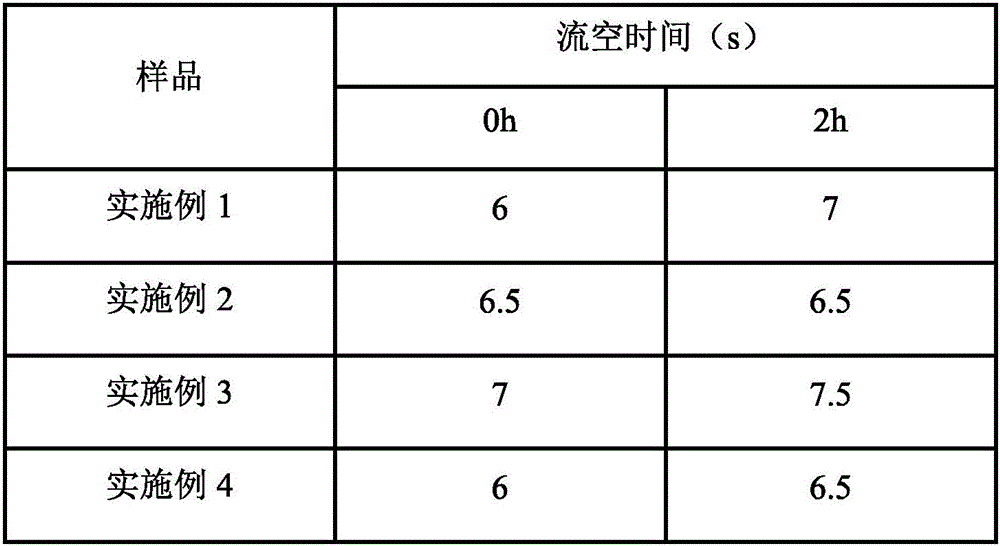

Examples

preparation example Construction

[0028] Concrete preparation method comprises as follows:

[0029] (1) Weigh each raw material component in proportion.

[0030](2) Dissolving the first unsaturated monomer in deionized water to form solution A, and dissolving ascorbic acid in deionized water to form solution B.

[0031] (3) Dissolve 2-methallyl polyoxyethylene ether and hydrogen peroxide in deionized water, adjust the reaction temperature, add solution A and solution B dropwise according to a certain rate of addition, and add sodium hydroxide after the reaction Adjust the pH value to neutral to obtain the water-reducing PCE mother liquor.

[0032] The mass concentration of the viscosity-reducing PCE mother liquor is 45-55%. It is obtained by free radical solution polymerization from allyl polyoxyethylene ether and the second unsaturated monomer using a redox initiation system; the number-average molecular weight of its active ingredients 10000~20000, the structural formula is where R 4 -H or -CH 3 , M is...

Embodiment 1

[0043] First add 798.38kg of water into the 1000L reactor, and then add EVONIK SitrenAirVoid 6010.25kg, TAKEMOTO Chupol AFK-2 0.15kg, aminotrimethylene phosphonic acid 3.94kg, benzotriazole 0.05kg and Cathone 0.10kg, and stir for 30 minutes , then add water-reducing PCE mother liquor PCE-1 98.57kg, viscosity-reducing PCE mother liquor PCE-524.64kg and slump-preserving PCE mother liquor PCE-9 73.92kg, and continue stirring until it dissolves into a uniform solution with a mass concentration of 10 %, that is, the viscosity-reducing polycarboxylate water-reducer for high-strength concrete.

Embodiment 2

[0045] Add 798.86kg of water to the 1000L reactor first, then add 0.10kg of BASF MasterAir 303A, 0.2kg of TAKEMOTO ChupolAFK-2, 3.45kg of monoethanol diisopropanolamine, 0.10kg of carboxybenzotriazole, and 0.05kg of paraben kg, after stirring for 30min, add water-reducing PCE mother liquor PCE-2 123.28kg, viscosity-reducing PCE mother liquor PCE-624.66kg and slump-preserving PCE mother liquor PCE-10 49.31, and continue stirring until it dissolves into a uniform solution. The mass concentration is 10%, that is, the viscosity-reducing polycarboxylate water reducer for high-strength concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com