A kind of atmospheric pressure drying prepares the method for bulky flexible airgel

A dry and flexible technology at atmospheric pressure, applied in the field of aerogel materials, the preparation of bulk flexible aerogels by atmospheric pressure drying, can solve the problems of pore size, broken pore structure, etc., achieve high porosity, low density, support Stress uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

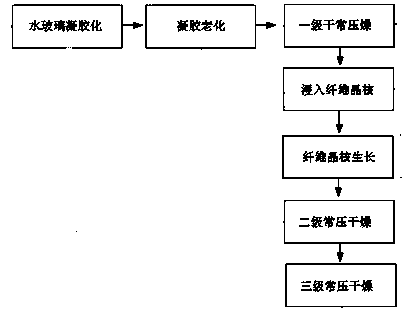

Method used

Image

Examples

Embodiment 1

[0029] (1) Mix deionized water and industrial water glass evenly, stir well, add acetic acid solution, adjust the pH to 5-8, and leave it for 1 hour to form a hydrogel;

[0030] (2) Pour the hydrogel obtained in step (1) into a leachable block mold, and continuously age it through 25% ammonia-containing ammonia solution, then rinse with water to obtain the aged wet gel, and place it naturally through the leachable The mold drains naturally;

[0031] (3) The aging wet gel obtained in step (2) is dried at a temperature of 60-80℃, and the drying time is controlled at 35 minutes. After the first drying, enough liquid phase is filled in the gel pores, The decrease in glue volume is equal to the volume of liquid evaporation. At this time, the gel network will not collapse and has toughness, and then continuously pass the calcium chloride solution saturated with the fiber crystal nucleus solution to make the fiber crystal nucleus enter the gel network;

[0032] (4) The gel obtained in step...

Embodiment 2

[0036] (1) Mix deionized water and industrial water glass uniformly, stir evenly, add sulfuric acid solution, adjust the pH to 5-8, and leave it for 1 hour to form a hydrogel;

[0037] (2) Pour the hydrogel obtained in step (1) into a leachable block mold, continuously age through ammonia solution, and then rinse with water to obtain an aged wet gel;

[0038] (3) The aging wet gel obtained in step (2) is dried at a temperature of 60-80℃, and the drying time is controlled at 25 minutes. After the first drying, enough liquid phase is filled in the gel pores, and the gel The decrease in glue volume is equal to the volume of liquid evaporation. At this time, the gel network will not collapse and is tough, and then continuously pass through the calcium acetate fiber crystal nucleus liquid to make the fiber crystal nucleus enter the gel network;

[0039] (4) The gel obtained in step (3) is continuously passed through sodium silicate aqueous solution and sodium hydroxide aqueous solution, a...

Embodiment 3

[0043] (1) Mix deionized water and industrial water glass evenly, stir evenly, add citric acid solution, adjust the pH to 5-8, and leave it for 1 hour to form a hydrogel;

[0044] (2) Pour the hydrogel obtained in step (1) into a leachable block mold, continuously age through ammonia solution, and then rinse with water to obtain an aged wet gel;

[0045] (3) The aging wet gel obtained in step (2) is dried at a temperature of 60-80℃, and the drying time is controlled at 30 minutes. After the first drying, enough liquid phase is filled in the gel pores, and The decrease in glue volume is equal to the volume of liquid evaporation. At this time, the gel network will not collapse and is tough, and then continuously pass through the calcium nitrate fiber crystal nucleus liquid to make the fiber crystal nucleus enter the gel network;

[0046] (4) The gel obtained in step (3) is continuously passed through sodium silicate aqueous solution and sodium hydroxide aqueous solution, and is initiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com