Triazinyl rare earth complex nanomaterial and preparation method and application thereof

A technology of rare earth complexes and nanomaterials, which is applied in the direction of nanotechnology, nanotechnology, and material electrochemical variables. It can solve the problems of limited types and quantities of chiral stationary phases, compounds that cannot be directly separated and analyzed, and high instrument costs. The method is simple, the sensitivity is high, and the effect of the preparation method is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

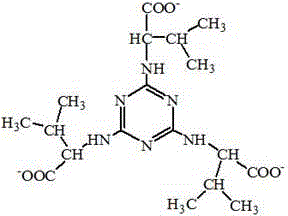

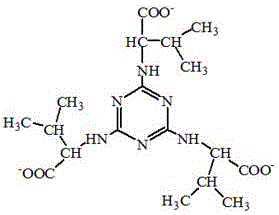

[0028] Example 1 Preparation of triazinyl tricarboxylic acid H 3 L

[0029] To 0.045mol of L-valine, add 20mL of water to mix, continue to add 6.0g of sodium hydroxide, ultrasound to form a clear sodium L-valine solution; another 0.015mol of cyanuric chloride, add 20ml Water, start stirring and ice-bath cooling to form a white turbid liquid; add L-valine sodium solution dropwise to the turbid liquid, continue the ice-bath reaction for 1 hour after the addition, then react at room temperature for 2 hours, warm to 110°C and reflux overnight ; Cool to room temperature, add hydrochloric acid to neutralize to pH 2, suction filter, and wash with ethanol and a small amount of water, the white solid obtained is dried at 80 ℃, that is, the triazinyl tricarboxylic acid ligand H 3 L, the yield is 76-80%.

Embodiment 2

[0030] Example 2 Preparation of triazinyl rare earth complex nanomaterial

[0031] To 0.2 mmol triazinyl tricarboxylic acid ligand H 3 Add 0.6 mL of KOH aqueous solution with a mass fraction of 6.25% to L, and dissolve it by ultrasound; take another 0.2 mmol of cerium nitrate hexahydrate and dissolve it in 0.4 mL of water; blend the two solutions and ultrasound for 10 seconds to obtain a white inverted For a non-flowing gel, activate the gel at 80°C for 3 days; wash it three times with 2 mL of ethanol and centrifuge to obtain a solid powder, which is dried at 40-60°C to prepare a triazinyl rare earth complex nanomaterial. The yield was 65%.

Embodiment 3

[0032] Example 3 Preparation of nanomaterials of triazinyl rare earth complexes

[0033] To 0.2mmol triazinyl tricarboxylic acid ligand H 3 In L, add 1.8 mL of KOH aqueous solution with a mass fraction of 6.25% and dissolve it by ultrasonic; take another 0.26 mmol of cerium nitrate hexahydrate and dissolve in 1.2 mL of water; blend the two solutions and ultrasonic for 30 seconds to obtain a white inverted For a non-flowing gel, activate the gel at 80°C for 3 days; wash it with 2-6mL of ethanol three times and centrifuge to obtain a solid powder, which is dried at 40-60°C to prepare a triazinyl rare earth complex nano Material, the yield is 73%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com