Cooperative medicament level sodium alginate and alginate-originated oligosaccharide technological method

A technology of algin oligosaccharides and algin, which is applied in the direction of fermentation, etc., can solve the problems of not meeting the use standards of pharmaceutical grade algin and high content of heavy metals, and achieve the effect of low endotoxin, low content of heavy metals, and increased ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

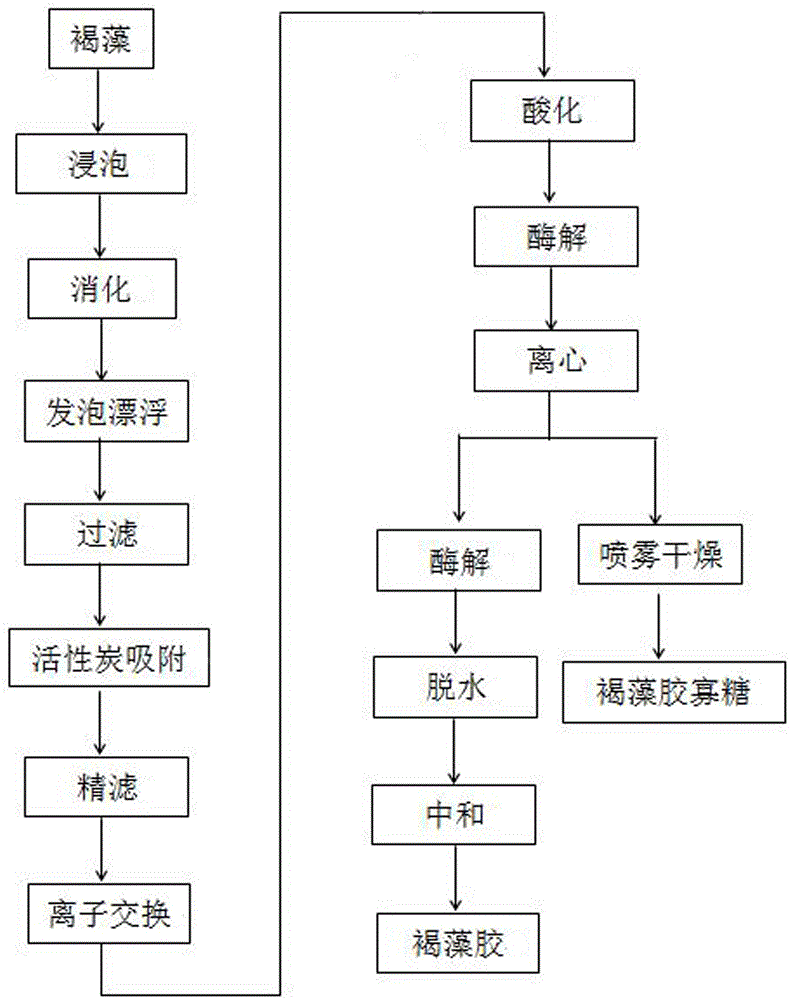

Method used

Image

Examples

Embodiment 1

[0034] Pharmaceutical grade alginate and alginate oligosaccharides were prepared as follows:

[0035] (1) 100 kg of dried kelp, soaked in 1.5m³ of water for 3 hours to make the kelp fully soaked and swelled, cut into 5cm strips with a vegetable cutter after controlling the water, and washed three times.

[0036] (2) Put the washed kelp into a digester, add 300 kg of tap water, add 12 kg of sodium fluoride under stirring, keep it warm at 60°C for 3 hours, break the kelp into a viscous state by mechanical means, and obtain Kelp digestive glue.

[0037] (3) Add 10 cubic meters of water to the kelp digestive juice obtained in step 2 to dilute, use compressed air to foam the glue, float and let stand for 2 hours after foaming.

[0038] (4) After coarsely filtering the glue solution obtained in step 3 through a centrifuge, add 20 kg of diatomaceous earth, filter it with a plate and frame filter press to obtain a clear solution, and use NaOH to adjust the pH of the glue solution to ...

Embodiment 2

[0047] (1) 100 kg of dried kelp, soaked in 1.5m³ of water for 3 hours to make the kelp fully soaked and swelled, cut into 5cm strips with a vegetable cutter after controlling the water, and washed three times.

[0048] (2) Put the washed kelp into a digester, add 300 kg of tap water, add 15 kg of sodium carbonate under stirring, and react at a constant temperature of 60°C for 4 hours, break the kelp into a viscous state with a machine, and obtain kelp digestion Glue.

[0049] (3) Add 10 m³ of water to the kelp digestive juice obtained in step 2 to dilute, use compressed air to foam the glue, float and stand for 2 hours after foaming.

[0050] (4) After coarsely filtering the glue solution obtained in step 3 through a centrifuge, add 20 kg of diatomaceous earth, and press filter with a plate and frame filter press to obtain a clear solution.

[0051] (5) Add 50 kg of activated carbon to the clear liquid obtained in step 4, and keep stirring for 60 minutes at 50°C.

[0052] (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com