Method of promoting polyolefin grafting reaction

A technology of grafting reaction and polyolefin, which is applied in the field of polyolefin modification, can solve the problems of limited number of polar groups and low efficiency of grafting reaction, and achieve good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

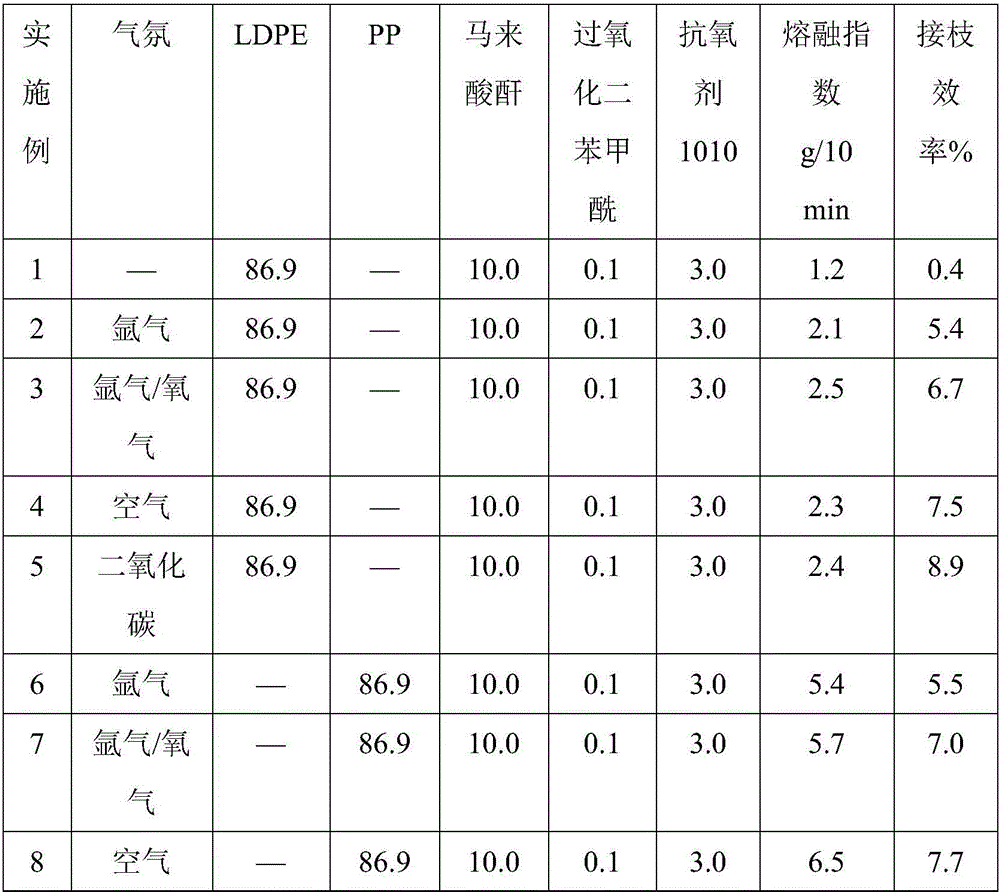

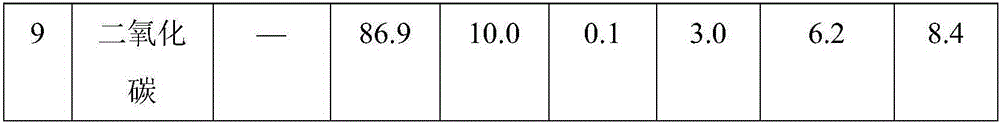

[0034] Embodiment 1: comparative example

[0035] Weigh 86.999 parts of LDPE (parts by weight, the same below, Yanshan Petrochemical LD160, melt index 5.0g / 10min), 10.0 parts of maleic anhydride, 0.001 parts of dibenzoyl peroxide, 3.0 parts of antioxidant 1010, and Dissolve dibenzoyl in 5.0 parts of acetone, mix low-density polyethylene, dibenzoyl peroxide solution, maleic anhydride, and antioxidant 1010 in a high-speed mixer for 60 minutes, and add the above mixture to the hopper of the extruder In the process, the temperature of each zone of the extruder is between 150°C and 180°C, the speed of the main screw is 60 rpm, and the speed of the feeding screw is 70 rpm. Bulk graft modified polyolefin particles.

Embodiment 2

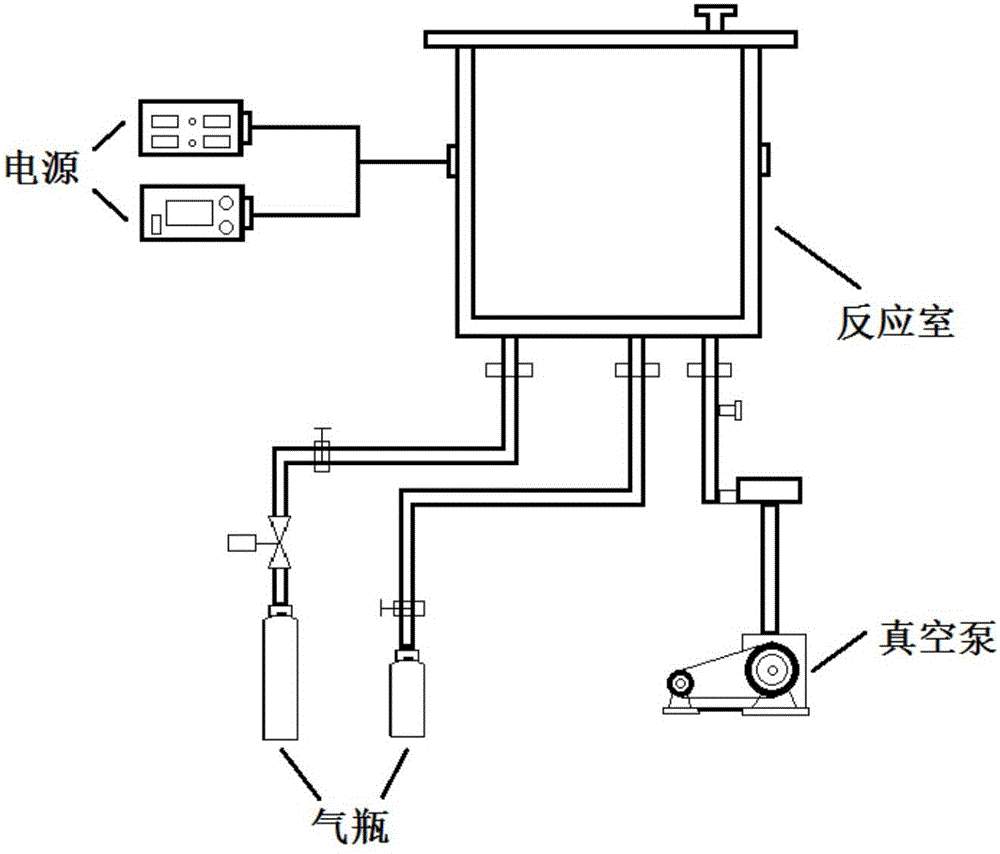

[0037] Weigh 86.999 parts of LDPE (parts by weight, the same below, Yanshan Petrochemical LD160, melt index 5.0g / 10min), 10.0 parts of maleic anhydride, 0.001 parts of dibenzoyl peroxide, 3.0 parts of antioxidant 1010, and Dibenzoyl was dissolved in 5.0 parts of acetone. Place LDPE in a low-temperature plasma reaction device, such as figure 1 As shown, first vacuumize, feed argon, gas pressure 50Pa, radio frequency discharge power 30W, discharge time 20min, then surface modified LDPE, maleic anhydride, dibenzoyl peroxide solution, antioxidant 1010 at high speed Mix in the mixer for 60 minutes, put the mixture into the hopper of the extruder, and react under the conditions of 80°C, the main screw speed is 50 rpm, and the feeding screw speed is 70 rpm, and the extruded product is drawn, cooling, drying and pelletizing to obtain polyolefin particles grafted with polar compounds. Among them, low-temperature plasma reaction device and extruder are commonly used equipment in this ...

Embodiment 3

[0039] Weigh 86.999 parts of LDPE (parts by weight, the same below, Yanshan Petrochemical LD160, melt index 5.0g / 10min), 10.0 parts of maleic anhydride, 0.001 parts of dibenzoyl peroxide, 3.0 parts of antioxidant 1010, and Dibenzoyl was dissolved in 5.0 parts of acetone. Put LDPE in a low-temperature plasma reaction device, pass through argon / oxygen (volume ratio 4 / 1) mixed gas, gas pressure 50Pa, radio frequency discharge power 30W, discharge time 20min, then surface modified LDPE, maleic anhydride , dibenzoyl peroxide solution, and antioxidant 1010 were mixed in a high-speed mixer for 60 minutes, and the mixture was put into the hopper of the extruder, at 80°C, the main screw speed was 50 rpm, and the feeding screw speed was 70 rpm The reaction is carried out under the condition of 1 / min, and the extruded product is drawn, cooled, dried and pelletized to obtain polyolefin particles grafted and modified by polar compounds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com