Method for preparing efficiently hydrophobic and oil-absorbing sponge with fluorine-containing silane coupling agent as cross-linking agent

A technology of silane coupling agent and oil-absorbing sponge, which is applied in the field of preparation of high-efficiency hydrophobic oil-absorbing sponge, simple and efficient hydrophobic oil-absorbing sponge, can solve the problems of complex preparation process, high cost, low oil absorption rate, etc. The effect of mild conditions and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

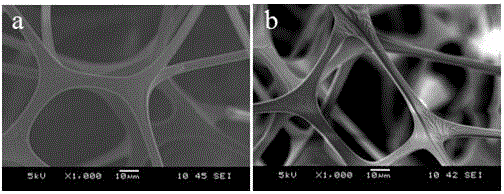

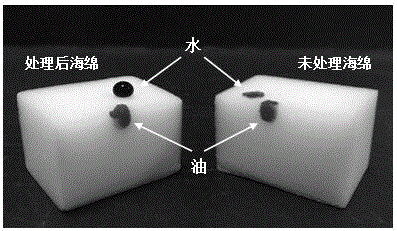

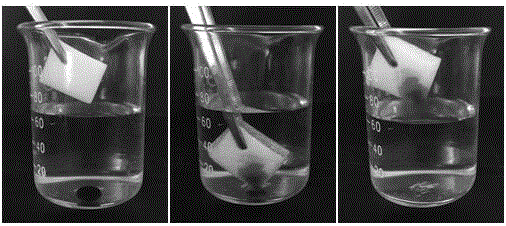

[0017] Add 3 mL of silane coupling agent perfluoropolyether siloxane in isopropanol (10% by mass) dropwise to 50 g of hydroxyl-terminated polydimethylsiloxane emulsion (30% solid), After stirring and mixing evenly, the silicone emulsion immersion solution was prepared; soak the washed and dried porous sponge in the immersion solution, and disperse it ultrasonically for 5 minutes. Cured in a drying oven for 8 h to constant weight, the highly efficient hydrophobic and oil-absorbing sponge was prepared.

Embodiment 2

[0019] Add 3 mL of silane coupling agent perfluoropolyether siloxane in isopropanol (10% by mass) dropwise to 50 g of hydroxyl-terminated polydimethylsiloxane emulsion (30% solid), After stirring and mixing evenly, the silicone emulsion immersion solution was prepared; soak the washed and dried porous sponge in the immersion solution, and disperse it by ultrasonic for 5 min. Cured in a drying oven for 10 hours to constant weight, the highly efficient hydrophobic and oil-absorbing sponge was obtained.

Embodiment 3

[0021] Add 3 mL of silane coupling agent perfluoropolyether siloxane in isopropanol (10% by mass) dropwise to 75 g of hydroxyl-terminated polydimethylsiloxane emulsion (20% solid), After stirring and mixing evenly, the silicone emulsion immersion solution was prepared; soak the washed and dried porous sponge in the immersion solution, and disperse it by ultrasonic for 5 min. Cured in a drying oven for 10 hours to constant weight, the highly efficient hydrophobic and oil-absorbing sponge was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com