Economical and environment-friendly external wall thermal insulating coating material and preparing method thereof

A technology of thermal insulation coating and coating material, applied in the direction of coating, anti-corrosion coating, reflection/signal coating, etc., can solve the problems of poor coating performance, poor dispersion of nanoparticles, and high price of nano-calcium carbonate, and achieve construction Convenience, improve thermal insulation performance, highlight the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

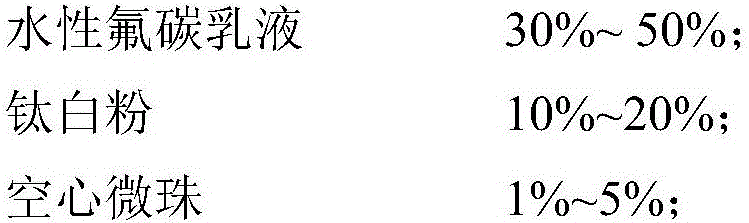

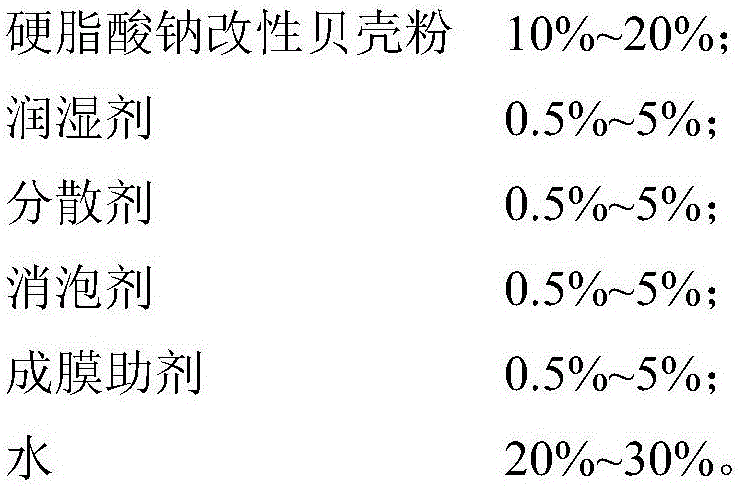

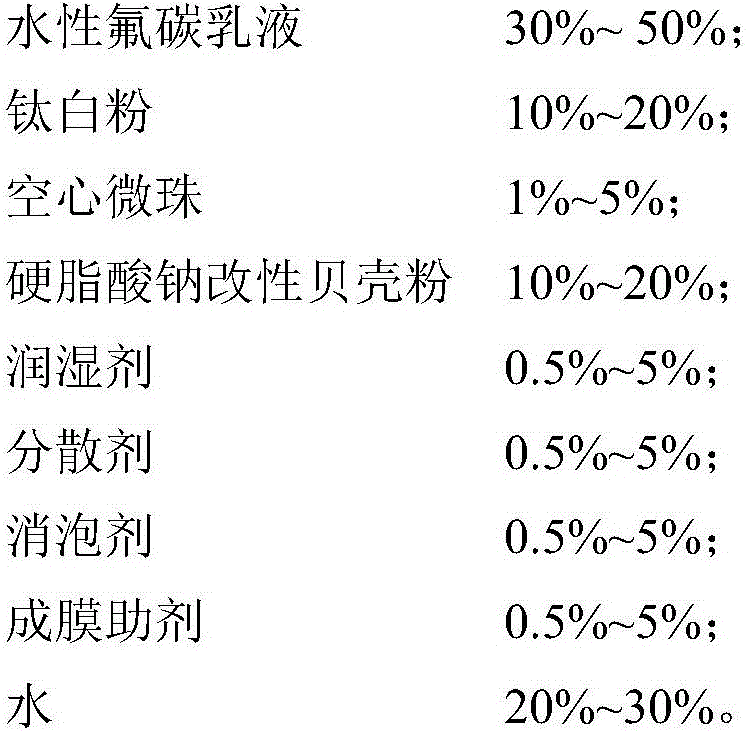

[0035] 1. Weigh the raw materials according to the following ratio:

[0036] Water-based fluorocarbon emulsion 50g;

[0037] Titanium dioxide 17g;

[0038] Hollow microspheres 1g;

[0039] Sodium stearate modified shell powder 10g;

[0040] Wetting agent 0.5g;

[0041] Dispersant 0.5g

[0042] Defoamer 0.5g;

[0043] Coalescing aid 0.5g;

[0044] 20g of water.

[0045] 2. Preparation of sodium stearate modified shell powder: weigh shell powder and sodium stearate with a mass of 0.1% to 3.0% of shell powder, dissolve it in alcohol 10 times the mass of shell powder, ultrasonically disperse for 30 minutes, and then Heating to 70°C, and stirring at a speed of 1000r / min for one hour during the heating process, filtering and drying after the stirring is completed, to obtain sodium stearate modified shell powder.

[0046] 3. Add titanium dioxide, sodium stearate modified shell powder, wetting agent, dispersant, defoamer and water to the water-based fluorocarbon emulsion, and ...

Embodiment 2

[0066] 1. Weigh the raw materials according to the following ratio:

[0067] Water-based fluorocarbon emulsion 30g;

[0068] Titanium dioxide 10g;

[0069] Hollow microspheres 5g;

[0070] Sodium stearate modified shell powder 20g;

[0071] Wetting agent 3g;

[0072] Dispersant 3g;

[0073] Defoamer 3g;

[0074] Film-forming aid 3g;

[0075] 23g of water.

[0076] The preparation of the coating in this example was carried out according to the preparation steps of Example 1, and an economical and environment-friendly exterior wall heat-insulating coating material with a dosage of sodium stearate modified shell powder of 20 g was obtained.

[0077] The solar reflectance of this economical and environmentally friendly exterior wall thermal insulation coating in the visible light band (420nm-720nm) and near-infrared band (720nm-2500nm) has reached 84%; the adhesion is grade 1, and there is no abnormality in the water resistance for 96 hours. No blistering, no peeling, no c...

Embodiment 3

[0079] 1. Weigh the raw materials according to the following ratio:

[0080] Water-based fluorocarbon emulsion 35g;

[0081] Titanium dioxide 20g;

[0082] Hollow microspheres 3g;

[0083] Sodium stearate modified shell powder 14g;

[0084] Wetting agent 1g;

[0085] Dispersant 0.5g;

[0086] Defoamer 1g;

[0087] Coalescing aid 0.5g;

[0088] 25g of water.

[0089] The preparation of the coating in this example was carried out according to the preparation steps of Example 1, and an economical and environment-friendly exterior wall heat-insulating coating with a dosage of sodium stearate modified shell powder of 14 g was obtained.

[0090] The solar reflectance of this economical and environmentally friendly exterior wall thermal insulation coating in the visible light band (420nm-720nm) and near-infrared band (720nm-2500nm) has reached 85%; the adhesion is level 1, and there is no abnormality in the water resistance for 96 hours. The weather resistance test No blister...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com