Application of lactobacillus pentosus SS6 to producing gamma-aminobutyric acid

A technology of Lactobacillus pentosus and aminobutyric acid, applied in the field of microorganisms, can solve the problems of slow growth of fungi, high cost, serious environmental pollution, etc., and achieve the effects of promoting growth hormone secretion, lowering cholesterol, and having wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

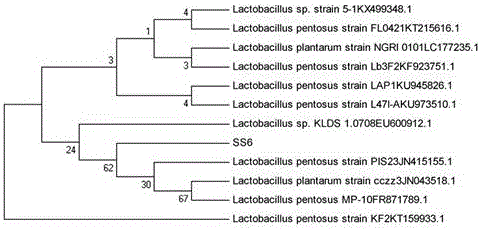

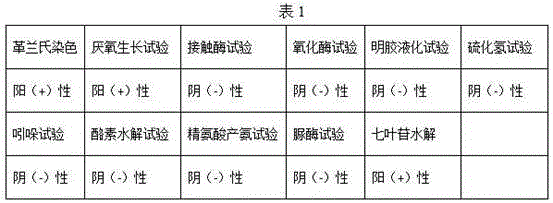

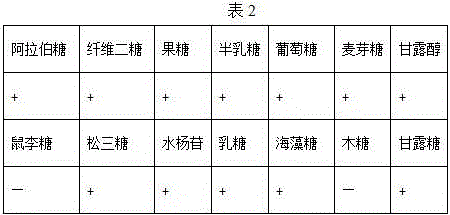

[0024] Example 1 Isolation, screening and identification of bacterial strains

[0025] Isolation of strains: Select mature mulberry fruits from healthy growing mulberry trees, rinse them with sterile water for 3 times in a sterile ultra-clean bench, then dry them with sterile filter paper, cut them into small pieces of 1 cm, put them in a mortar and grind them to get the juice, and absorb 100 μL The fruit juice was cultured in the MRS liquid medium for 2 days in a constant temperature incubator at 30°C. When the liquid medium became turbid, the bacterial liquid was diluted by the gradient dilution method, and the dilution was 10. -5 and 10 -6 Put 100 μL of the bacterial cell dilution solution in the lactic acid bacteria isolation medium, and incubate in a 30°C constant temperature incubator for 2 to 3 days. After colonies grow in the lactic acid bacteria isolation medium (round milky white or yellow colonies appear), the surrounding medium turns yellow. It was determined to b...

Embodiment 2

[0035] The cultivation of embodiment 2 bacterial strains

[0036] 1. Activation of Lactobacillus pentosus SS6: Aseptically operate in an ultra-clean workbench, pick Lactobacillus pentosus SS6 with an inoculation loop, streak on a plate medium (MRS medium) with an inoculation loop, and culture at 30°C Cultured in the box for 2 days.

[0037] 2. Preparation of fermentation samples of Lactobacillus pentosus SS6: Inoculate the isolated Lactobacillus pentosus SS6 into 50 mL of fermentation medium TYG, culture it in a 30°C incubator for 2 days, place the fermentation mixture in a boiling water bath for 10 minutes, and heat at 10000 r / h Centrifuge for 10 min, and take the upper liquid to obtain the fermentation broth.

[0038] 3. Drawing of γ-aminobutyric acid standard curve: Take 1.0mL distilled water and standard sample solutions of γ-aminobutyric acid with concentrations of 1mg / mL, 2mg / mL, 3mg / mL, 4mg / mL and 5mg / mL respectively, Add 120μL 1mol / L LaCl 3 Solution, mix and shake f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com