Method for preparing nano-hydroxyapatite gradient coating on titanium alloy matrix

A nano-hydroxyapatite, gradient coating technology, applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problem of unfavorable long-term implantation, low bonding strength, HA coating decomposition, etc. problems, to achieve the effect of retaining biological activity and stability, the process is simple and easy, and the production cycle is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

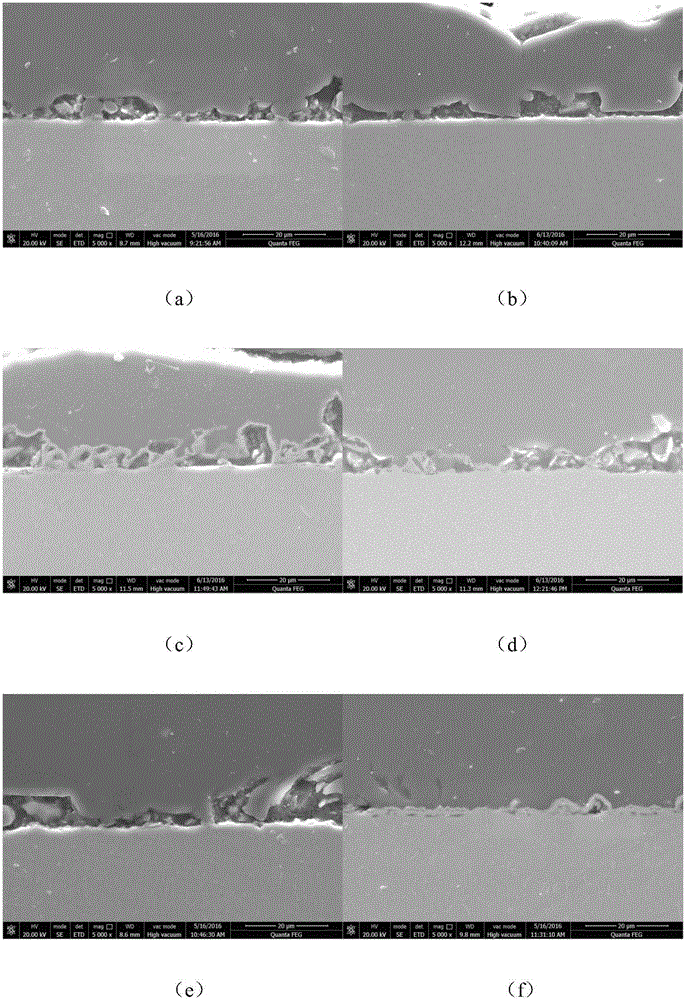

[0025] Example 1: Ti 13 Nb 13 After the inert ceramic transition layer was sintered on the Zr titanium alloy substrate at 810°C for 30 minutes, the HA coating was sintered on the transition layer at 810°C for 30 minutes, and the combined cross section of the coating was obtained as follows: figure 2 As shown in (a), it can be found that the coating bonding interface gap obtained under this process parameter is relatively large, and the coating bonding performance is not good. The measured coating adhesion is between 7MPa and 10MPa.

example 2

[0026] Example 2: Ti 13 Nb 13 After the inert porcelain transition layer was sintered on the Zr titanium alloy substrate at 830°C for 30 minutes, the HA coating was sintered on the transition layer at 830°C for 30 minutes, and the combined cross section of the coating was obtained as follows: figure 2 As shown in c and d, it can be found that the coating bonding interface gap obtained under this process parameter is smaller than the coating gap obtained in Example 1, and the coating bonding performance is also better. The measured coating adhesion is between 12MPa and 17MPa.

[0027] Example 3: Ti 13 Nb 13 After the inert ceramic transition layer was sintered on the Zr titanium alloy substrate at 850 °C for 30 minutes, the HA coating was sintered on the transition layer at 850 °C for 30 minutes, and the combined cross section of the coating was obtained as follows: figure 2 As shown in c and d, it can be found that the coating bonding interface gap obtained under this pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com