Open-and-close type three-dimensional trench electrode silicon detector

A grooved electrode, open-close technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of single-sided incident of particles, large dead zone, affecting the detection performance of the detector, etc., to achieve sensitive response, high detection efficiency, The effect of reducing the ratio of the dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

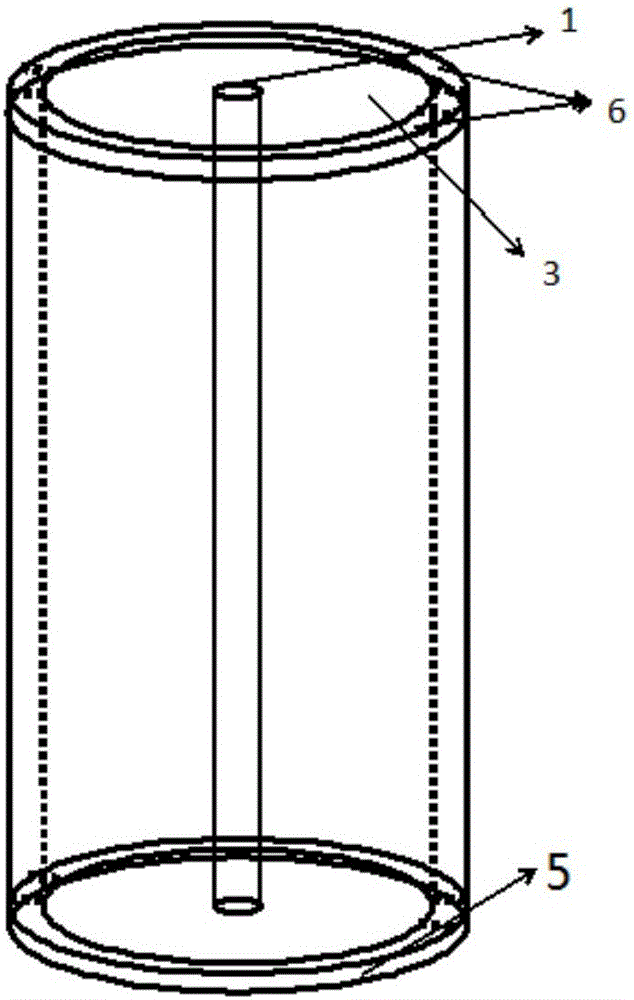

[0022] The structure of the present invention, such as figure 2 , Figure 4 As shown, the open-close trench electrode 6 and the central electrode 1 are formed through diffusion doping on the silicon body 3, and the open-close trench electrode 6 surrounds the central electrode 1, and the open-close trench electrode 6 exists Open, discontinuous cylindrical structure, the inner arc length S of the opening of the split trench electrode 6 is 10 μm, and a 1 μm silicon dioxide protective layer 5 is provided at the bottom of the entire structure.

[0023] The central electrode 1 is a hollow cylinder. The central electrode 1 is connected to the negative electrode. Its radius is 5 μm. The uppermost layer is 1 μm aluminum, and the lower layer of the aluminum layer is 200 μm heavily doped borosilicate. The heavily doped borosilicate is a donor and provides electrons. The split trench electrode 6 is a hollow cylindrical ring, the split trench electrode 6 is connected to the positive elec...

Embodiment 2

[0025] Embodiment 2, the structure of the present invention, except that the arc length S inside the opening of the open-close trench electrode 6 is 3 μm, and the thicknesses of heavily doped borosilicate, heavily doped phosphorus silicon, and lightly doped borosilicate are all 500 μm, the rest Part is the same as Example 1.

Embodiment 3

[0026] Embodiment 3, the structure of the present invention, except that the arc length S inside the opening of the open-close trench electrode 6 is 8 μm, and the thicknesses of heavily doped borosilicon, heavily doped phosphorus silicon, and lightly doped borosilicate are all 300 μm, the rest Part is the same as Example 1.

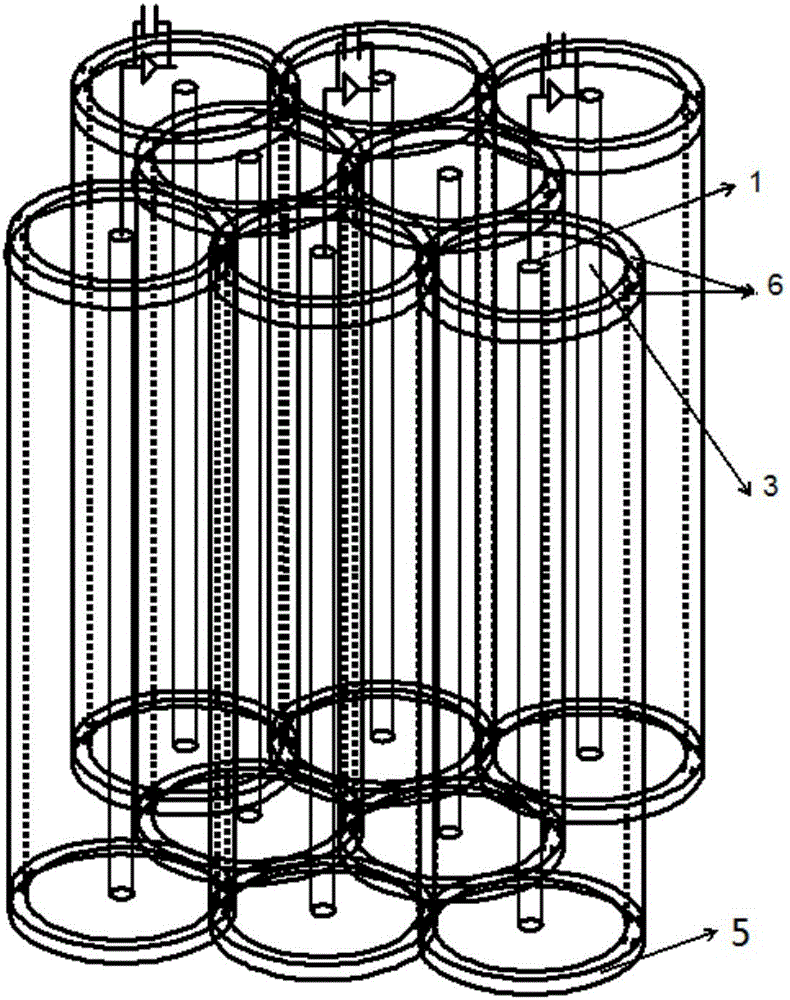

[0027] The structure of the array of the present invention, such as image 3 shown by figure 2 A single detector unit structure is combined.

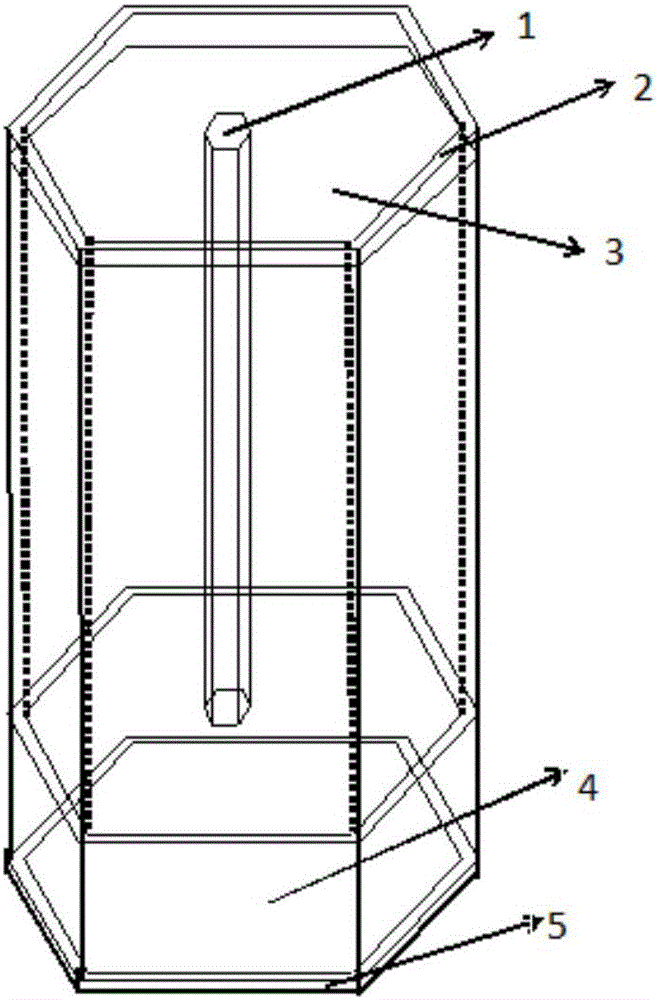

[0028] In terms of technology, the trench electrode is etched by a photolithography machine and ion implanted. The traditional "three-dimensional trench electrode silicon detector" can only be etched on one side, and the particles are injected on one side, but the split trench electrode 6 of the split three-dimensional trench electrode silicon detector of the present invention is formed when the groove is etched. The hexagonal or circular structure formed by incomplete etching can be etched on the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com