Nitrogen-doped carbon nanotube/carbon composite oxygen reduction catalyst and preparation method thereof

A carbon nanotube, nitrogen-doped carbon technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of complex operation, harsh reaction conditions, unfavorable large-scale use, etc., achieving simple operation steps, flexible design, Structure and composition controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

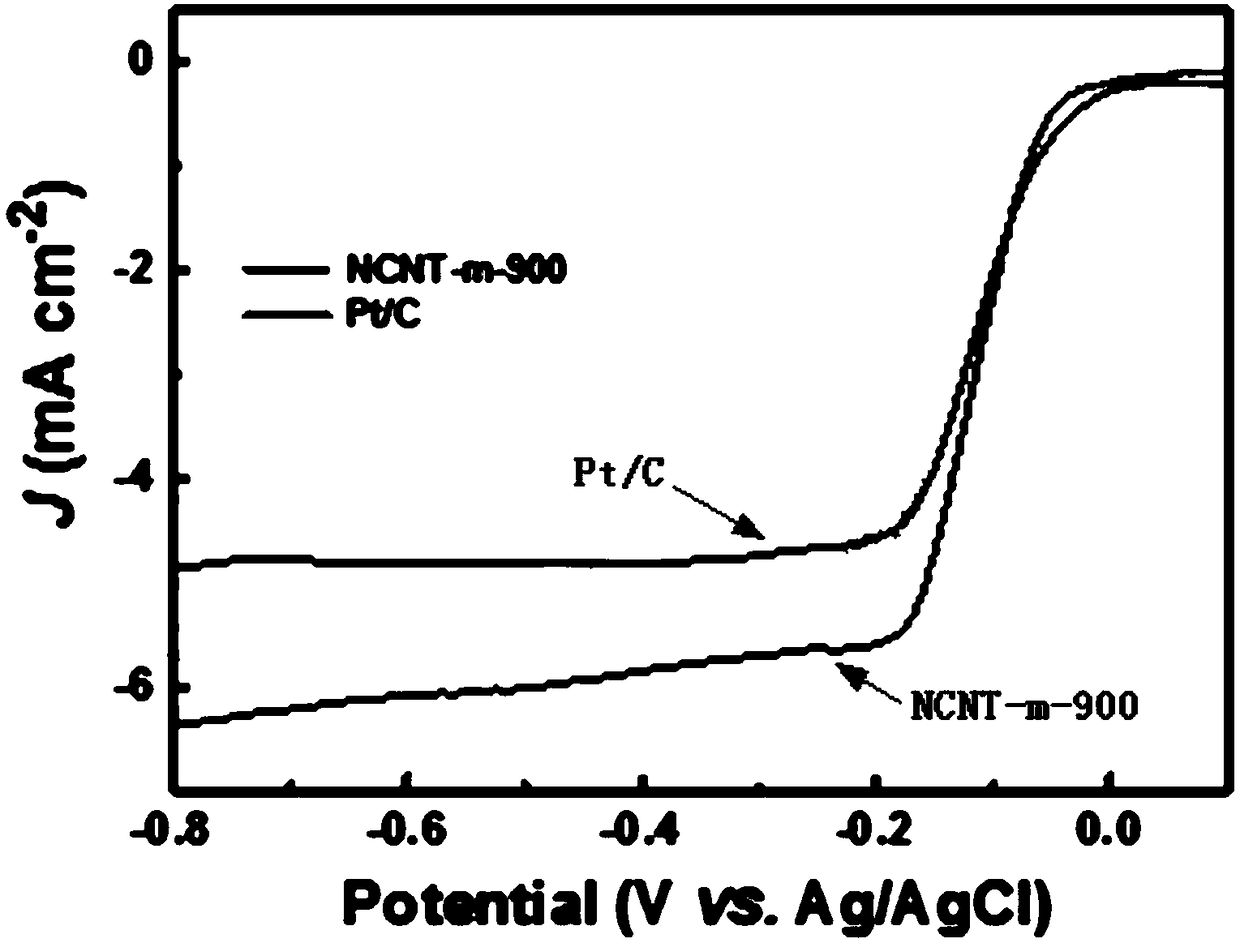

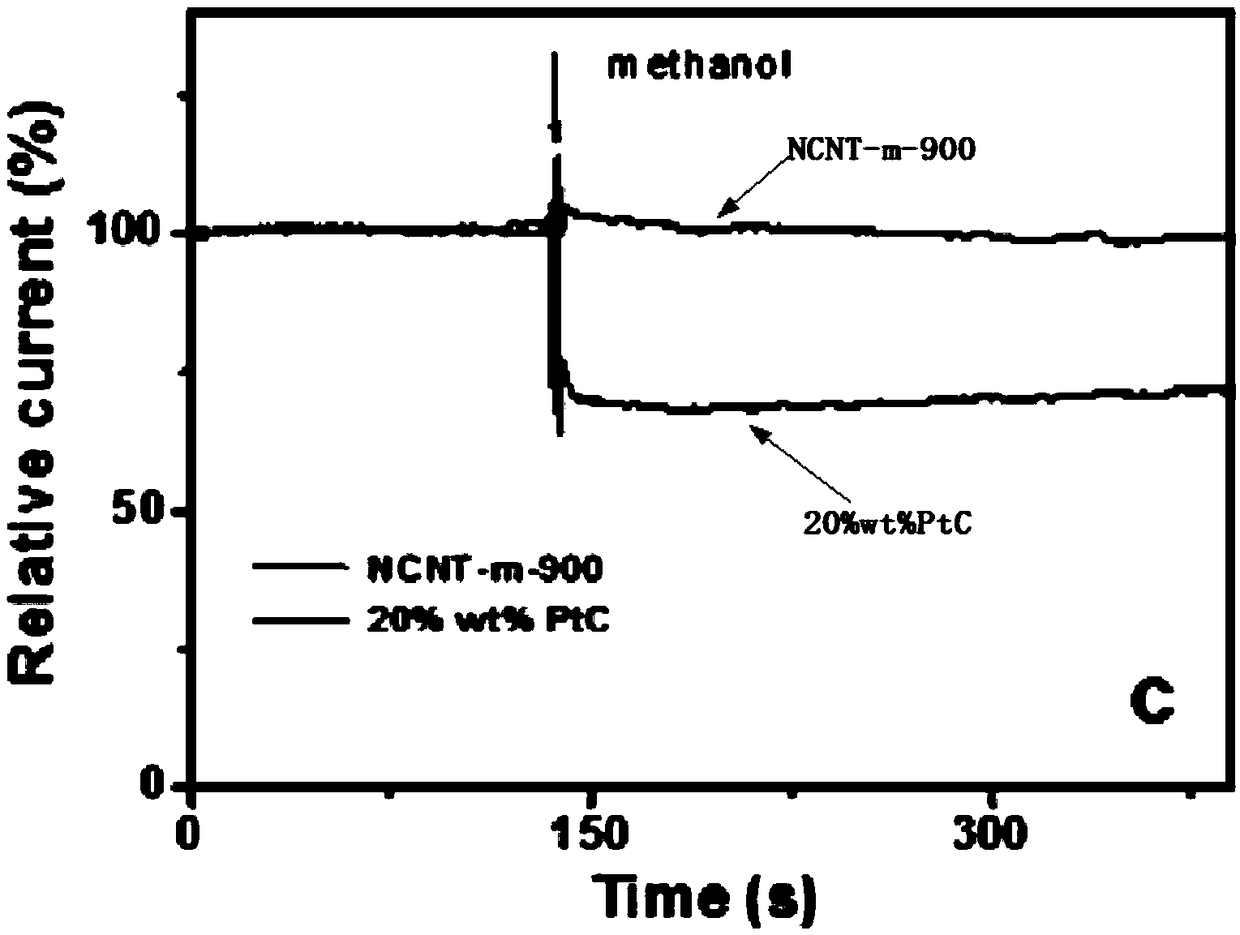

[0080] According to the second embodiment provided by the present invention, a method for preparing a nitrogen-doped carbon nanotube / carbon composite oxygen reduction catalyst is provided. The method includes the following steps:

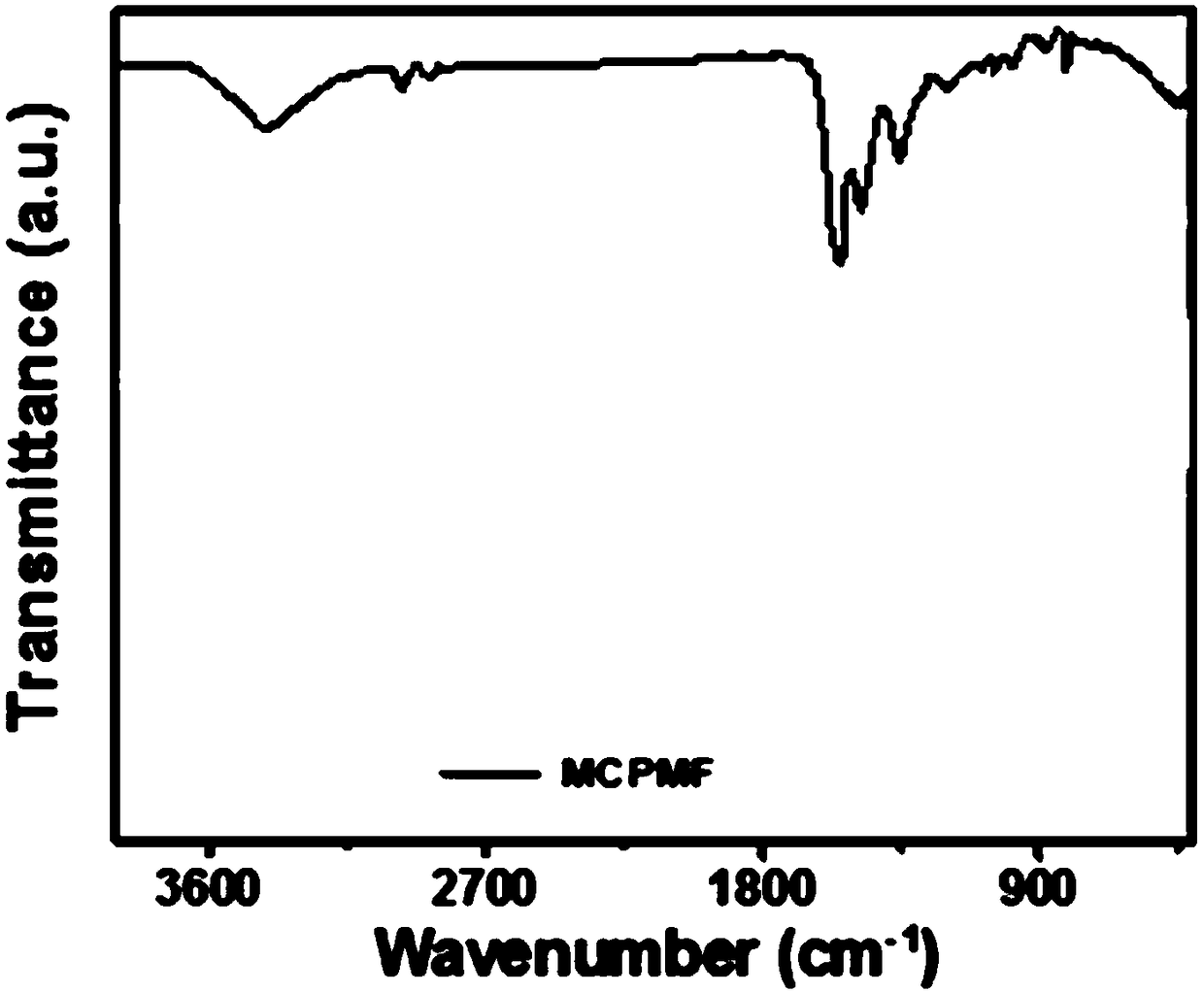

[0081] 1) Preparation of carbon nanotube / melamine composite (CNT-MAM): put CNTs in an absolute ethanol environment, mix and disperse, then add melamine (MAM) for reflux stirring, after cooling, perform suction filtration and washing, Obtain carbon nanotube / melamine composite (CNT-MAM) after drying;

[0082] 2) Preparation of carbon nanotube / poly(melamine-aldehyde) composite: the obtained carbon nanotube / melamine composite (CNT-MAM) was dispersed in anhydrous dimethyl sulfoxide (DMSO) or DMSO aqueous solution, Then add it to the reaction kettle lined with polytetrafluoroethylene, add melamine (MAM) and aldehyde-containing compound in sequence under stirring, stir and react after heating, reheat, and crush, wash, and dry the obtained solid after cooli...

Embodiment 1

[0091] A preparation of nitrogen-doped carbon nanotube / carbon composite oxygen reduction catalyst, comprising the steps of:

[0092] (1) Preparation of carbon nanotube / melamine composite (CNT-MAM): put 1000mg of CNTs and 200mL of absolute ethanol in a 500mL round-bottomed flask, and then ultrasonically disperse the CNTs for 30min, then add 2000mg of melamine (MAM), stirring at reflux for 24h. Cool to room temperature, filter with PTFE membrane, wash the product with 80°C hot water and ethanol three times, and finally dry in a vacuum oven for 8 hours.

[0093] (2) Preparation of carbon nanotube / poly(melamine-formaldehyde) composite: Disperse carbon nanotube / melamine (CNT-MAM) (2.5 g) prepared in step (1) in 33.6 mL of anhydrous DMSO, and then Add it into a reaction kettle lined with polytetrafluoroethylene, add MAM (3.78g, 30mmol) and formaldehyde (1.62g, 54mmol) sequentially under stirring, then place it in a 120°C oven at constant temperature for 1h, take it out and stir to ...

Embodiment 2

[0096] A preparation of nitrogen-doped carbon nanotube / carbon composite oxygen reduction catalyst, comprising the steps of:

[0097] (1) Preparation of carbon nanotube / melamine composite (CNT-MAM): Weigh 1000mg of CNTs and 200mL of absolute ethanol in a 500mL round-bottomed flask, then ultrasonically sonicate for 30min to fully disperse the CNTs, then add 2000mg of melamine (MAM), stirring at reflux for 24h. Cool to room temperature, filter with PTFE membrane, wash the product with 80°C hot water and ethanol three times, and finally dry in a vacuum oven for 8 hours.

[0098] (2) Preparation of carbon nanotube / poly(melamine-benzaldehyde) composite: put CNT-MAM prepared in step (1) and melamine (6.3g, 50mmol), benzaldehyde (7.95g, 75mmol) in 500mL Add 200mL of anhydrous DMSO to the round bottom flask, and ultrasonically sonicate for 10min (40kHz) to fully disperse CNT-MAM in the reaction solvent. After sealing, blow argon to exhaust oxygen for 30min, and move it into a 170°C oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com