Polyester film, method for producing polyester film, polarizing plate, image display device, hard coat film, and touch panel

A manufacturing method, polyester film technology, applied in polarizing elements, instruments, optics, etc., can solve problems such as mechanical strength reduction, achieve less breakage, less scars, and suppress iridescent spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0346]

[0347] (raw material polyester 1)

[0348] As shown below, a direct esterification method in which terephthalic acid and ethylene glycol are directly reacted, water is distilled off, esterified, and then polycondensed under reduced pressure is used to obtain the raw material polyester using a continuous polymerization device. 1 (Sb catalyst-based PET).

[0349] (1) Esterification reaction

[0350] In the first esterification reaction tank, 4.7 tons of high-purity terephthalic acid and 1.8 tons of ethylene glycol were mixed for 90 minutes to form a slurry, which was continuously supplied to the first esterification reaction tank at a flow rate of 3800 kg / h . Furthermore, an ethylene glycol solution of antimony trioxide was continuously supplied, and the reaction was carried out at an average residence time of about 4.3 hours at a temperature of 250° C. in the reaction tank with stirring. At this time, antimony trioxide was continuously added so that the amount of ...

Embodiment 2~24、 comparative example 1~8

[0413] Except having changed the manufacturing conditions of the polyester film in Example 1 as described in following Table 1, it carried out similarly to Example 1, and manufactured the polyester films of Examples 2-24 and Comparative Examples 1-8.

[0414] In addition, various production conditions in the transverse stretching process and the shrinkage ratio of the distance between clips during heat setting were controlled by changing the setting of the tenter. In addition, in Comparative Example 5, the tenter was set so that the condition of Mathematical Expression 21 was always satisfied during stretching,

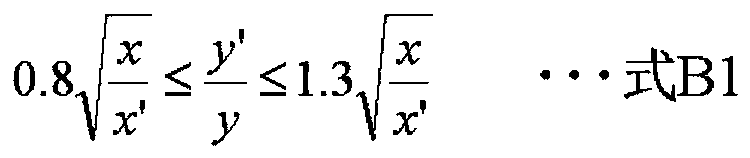

[0415] [Mathematical formula 21]

[0416]

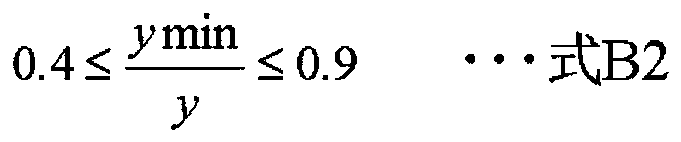

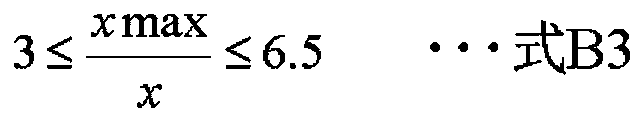

[0417] In Comparative Example 6, the tenter was set so that the condition of Mathematical Expression 22 was always satisfied during stretching.

[0418] [mathematical formula 22]

[0419]

[0420] In Examples 11, 12, 14, 16, 22, 24, and Comparative Example 8, the maximum attainable film surface temperature T2 during ...

Embodiment 25

[0423] (raw material polyester 2)

[0424] 10 parts by mass of dried ultraviolet absorber (2,2'-(1,4-phenylene)bis(4H-3,1-benzoxazin-4-one)), PET1 (IV=0.63) 90 parts by mass were mixed, and pelletized using a kneading extruder in the same manner as PET1, to obtain raw material polyester 2 (hereinafter, abbreviated as PET2) containing an ultraviolet absorber.

[0425] -Film forming process-

[0426] After drying 90 parts by mass of raw polyester 1 (PET1) and 10 parts by mass of raw polyester 2 (PET2) containing an ultraviolet absorber to a moisture content of 20 ppm or less, they are put into a single-screw kneading extruder 1 with a diameter of 50 mm. In the hopper 1 of the extruder 1, melt at 300°C. It was extruded from a die through a gear pump and a filter (pore size: 20 μm) under the following extrusion conditions.

[0427] Regarding the extrusion conditions of the molten resin, the pressure fluctuation was 1%, the temperature distribution of the molten resin was 2%, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com