Method for temperature-programmed synthesis of nanometer ZSM-5 molecular sieve used for methanol to propylene

A ZSM-5, temperature-programmed technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of prolonged synthesis time, excessively low crystallization temperature, etc. effect of chemical cycle, particle size reduction, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

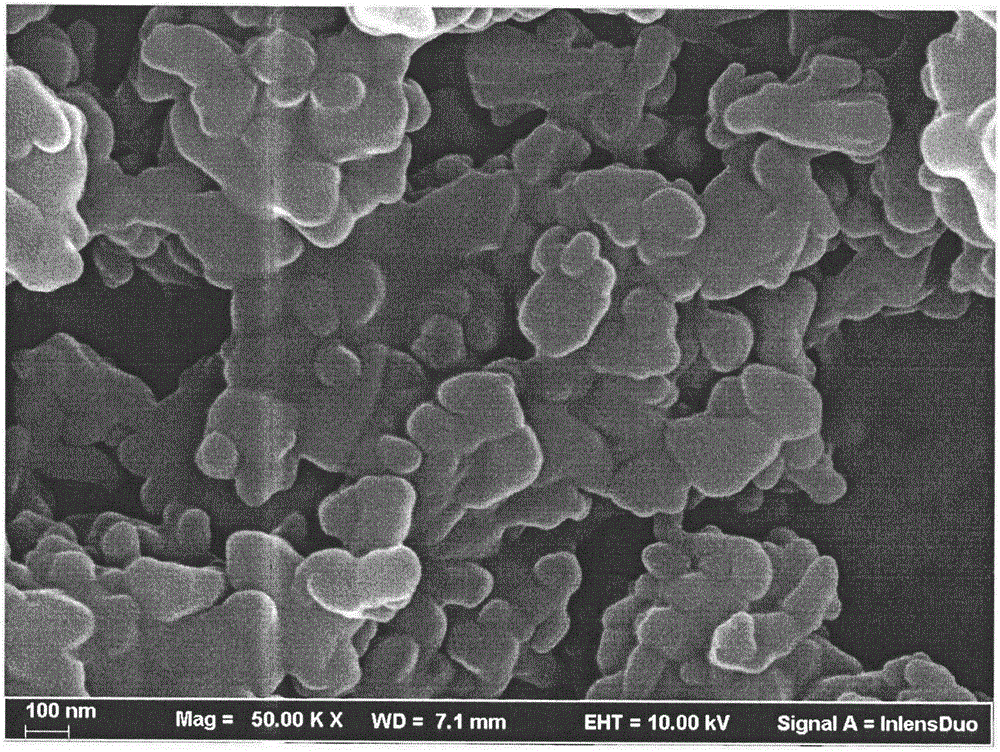

[0027] Add 7.04g of NaOH to 60.2g of distilled water, stir until a clear solution, add 1.3g of sodium metaaluminate into the above solution and stir until completely dissolved. Under magnetic stirring, slowly add 150g of silica sol dropwise to the above mixed solution to form aluminosilicate gel A; weigh a certain amount of tetrapropylammonium hydroxide, and add tetrapropylammonium hydroxide and aluminosilicate SiO2 in the salt gel The mass ratio is 0.25, the above-mentioned tetrapropyl ammonium hydroxide is added into the deionized water of 30.8g to obtain mixed solution B, under stirring condition, solution B is slowly added in A gel to make mixing, finally Transfer the mixture into a polytetrafluoroethylene-lined stainless steel crystallization kettle, raise the temperature from room temperature to 120°C at a rate of 5°C / hour, and then crystallize at 120°C for 20 hours; the product is filtered, washed, and dried at 85°C After 14 hours, calcination at 550°C for 10 hours, the...

Embodiment 2

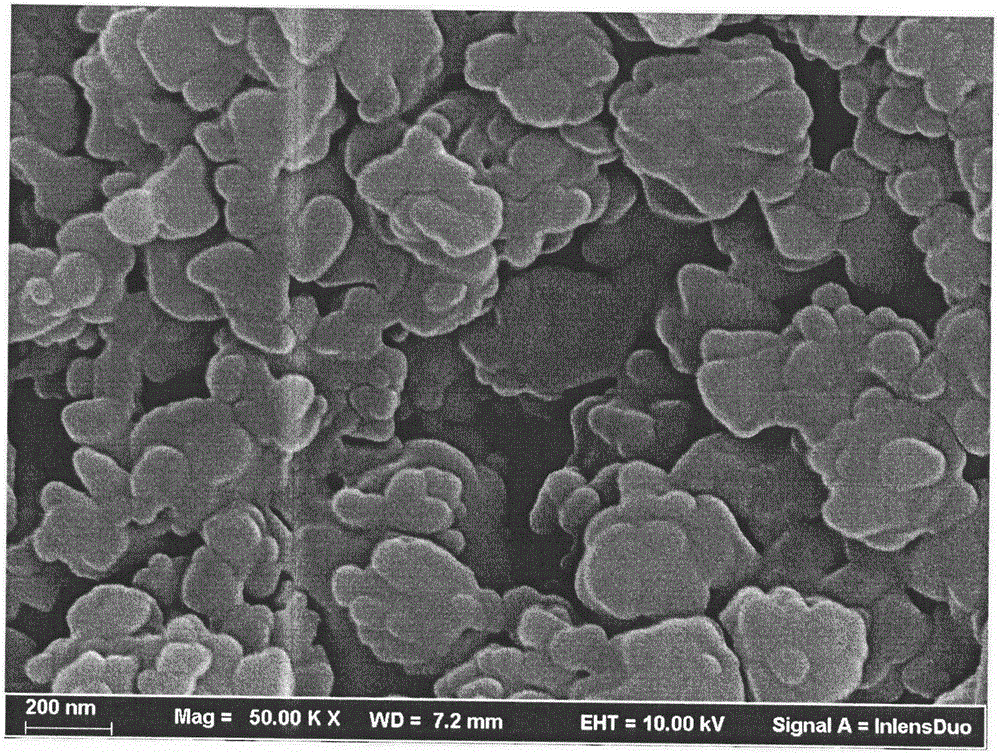

[0029] Add 7.04g of NaOH to 60.2g of distilled water, stir until a clear solution, add 1.3g of sodium metaaluminate into the above solution and stir until completely dissolved. Under magnetic stirring, slowly add 150g of silica sol dropwise to the above mixed solution to form aluminosilicate gel A; weigh a certain amount of tetrapropylammonium hydroxide, and add tetrapropylammonium hydroxide and aluminosilicate SiO2 in the salt gel The mass ratio is 0.25, the above-mentioned tetrapropyl ammonium hydroxide is added into the deionized water of 30.8g to obtain mixed solution B, under stirring condition, solution B is slowly added in A gel to make mixing, finally Transfer the mixture into a polytetrafluoroethylene-lined stainless steel crystallization kettle, raise the temperature from room temperature to 120°C at a rate of 10°C / hour, and then crystallize at 120°C for 20 hours; the product is filtered, washed, and dried at 85°C After 14 hours, calcination at 550° C. for 10 hours, ...

Embodiment 3

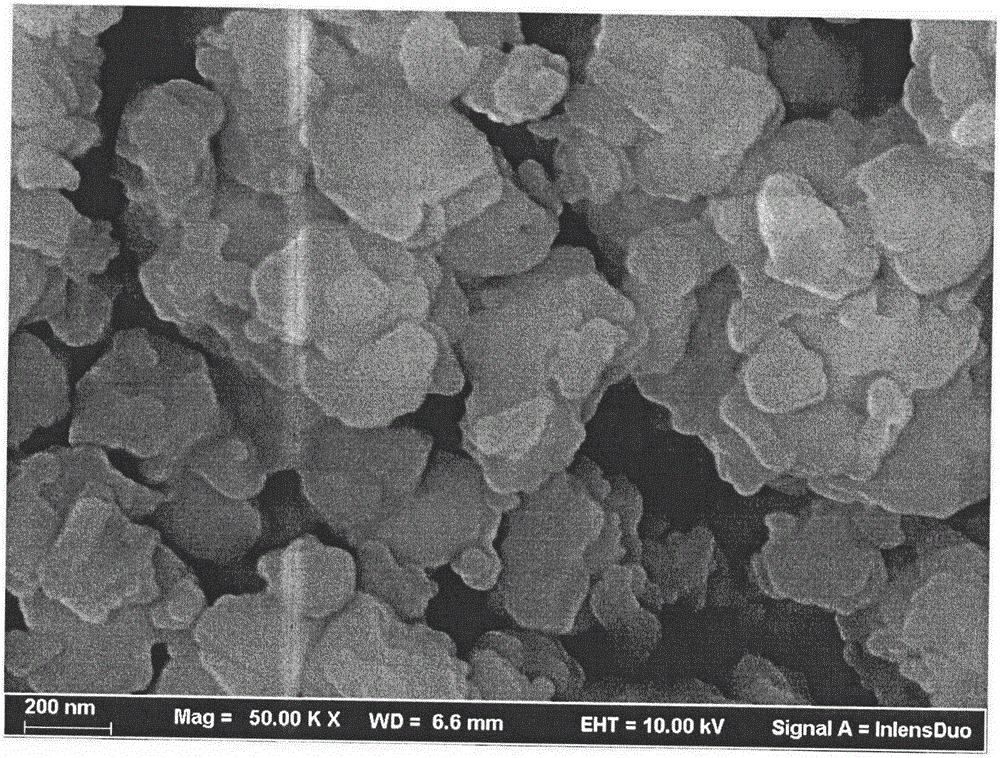

[0031] Add 7.04g of NaOH to 60.2g of distilled water, stir until a clear solution, add 1.3g of sodium metaaluminate into the above solution and stir until completely dissolved. Under magnetic stirring, slowly add 150g of silica sol dropwise to the above mixed solution to form aluminosilicate gel A; weigh a certain amount of tetrapropylammonium hydroxide, and add tetrapropylammonium hydroxide and aluminosilicate SiO2 in the salt gel The mass ratio is 0.25, the above-mentioned tetrapropyl ammonium hydroxide is added into the deionized water of 30.8g to obtain mixed solution B, under stirring condition, solution B is slowly added in A gel to make mixing, finally Transfer the mixture into a polytetrafluoroethylene-lined stainless steel crystallization kettle, raise the temperature from room temperature to 150°C at a rate of 5°C / hour, and then crystallize at 150°C for 12 hours; the product is filtered, washed, and dried at 85°C After 14 hours, calcination at 550°C for 10 hours, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com