Modified waterborne acrylic resin and method for preparing artificial color sand from modified waterborne acrylic resin

A water-based acrylic acid and butyl acrylate technology, applied in the field of artificial colored sand preparation, can solve the problems of poor weather resistance, insufficient color fastness and acid and alkali resistance, and achieve the effects of excellent wear resistance, bright color and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

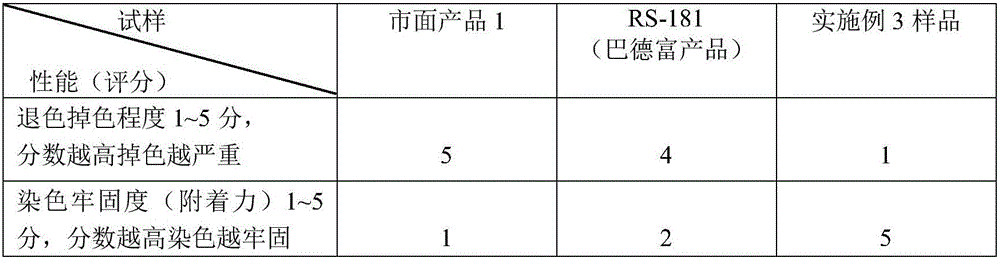

Examples

preparation example Construction

[0039] The preparation method of the modified water-based acrylic resin for preparing artificial colored sand of the present invention comprises the following process flow;

[0040] (1) Synthesis stage

[0041] a. Preparation of pre-emulsion: add 30% deionized water and 40% emulsifier in formula quantity, turn on the agitator, the rotating speed is 300Hz, drop into methyl methacrylate, butyl acrylate and hydroxyethyl acrylate in turn Esters, alkyl carboxylic acid cross-linking monomers, siloxanes, emulsifiers, persulfates and alkyl mercaptans, continue stirring for 30 minutes for later use;

[0042] b. Add the remaining deionized water and emulsifier into another reactor, stir evenly, and raise the temperature to 82°C; put in 5% pre-emulsion, and stir for 30 minutes;

[0043] c. Continuously and evenly drop the remaining pre-emulsion, keep warm at 81-83°C, add dropwise for 3 hours, and keep warm for 60 minutes after the dropwise addition;

[0044] (2) Post-processing stage ...

Embodiment 1

[0048] Embodiment 1 A kind of artificial colored sand water-based modified acrylic resin and its preparation

[0049] The present embodiment is made by following raw material proportioning, calculates by weight:

[0050] 320 parts of methyl methacrylate, 200 parts of butyl acrylate, 70 parts of hydroxyethyl acrylate, 14 parts of alkyl carboxylic acid crosslinking monomer, 3 parts of siloxane, 15 parts of emulsifier, 3.5 parts of persulfate, alkanes 3 parts of base mercaptan, 8 parts of ammonia water, 750 parts of water;

[0051] The alkyl carboxylic acid cross-linking monomer is: acrylic acid

[0052] The siloxane is: vinyltrimethoxysilane;

[0053] Described emulsifier is: sodium dodecylbenzenesulfonate;

[0054] Described persulfate is: ammonium persulfate;

[0055] Described alkyl mercaptan is: n-dodecyl mercaptan;

[0056] Its preparation method comprises the following steps:

[0057] (1) Synthesis stage

[0058] a. Preparation of pre-emulsion: add 30% deionized water...

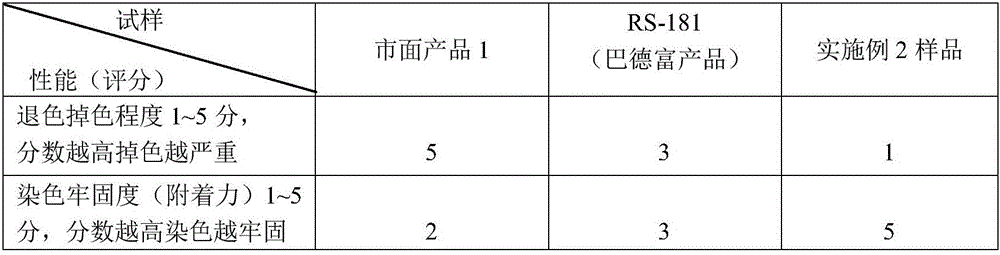

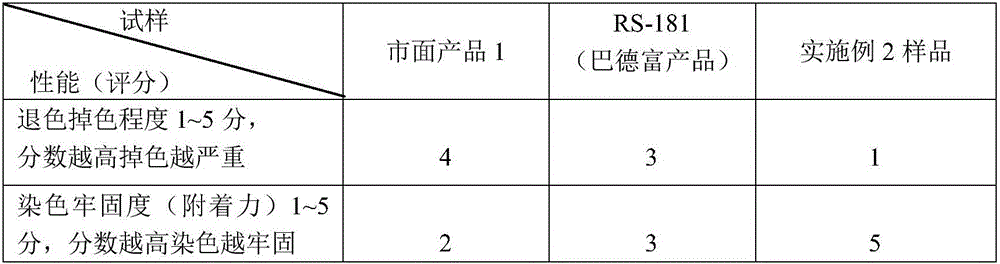

Embodiment 2

[0065] Embodiment 2 A kind of artificial colored sand water-based modified acrylic resin and its preparation

[0066] The present embodiment is made by following raw material proportioning, calculates by weight:

[0067] 340 parts of methyl methacrylate, 190 parts of butyl acrylate, 60 parts of hydroxyethyl acrylate, 12.8 parts of alkyl carboxylic acid crosslinking monomer, 4.5 parts of siloxane, 15 parts of emulsifier, 3.5 parts of persulfate, alkanes 3.5 parts of base mercaptan, 7.5 parts of ammonia water, and 780 parts of water.

[0068] The alkyl carboxylic acid cross-linking monomer is: 6 parts of acrylic acid, 6.8 parts of methacrylic acid

[0069] The siloxane is: vinyltriethoxysilane;

[0070] The emulsifier is: 10 parts of potassium dodecylbenzenesulfonate, 5 parts of sodium lauryl polyoxyethylene ether sulfate;

[0071] Described persulfate is: sodium persulfate;

[0072] Described alkyl mercaptan is: isododecyl mercaptan;

[0073] The preparation process is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel fraction | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com