Temporarily blocked high temperature kill fluid suitable for low permeability reservoir and preparation method thereof

A low-permeability, well-killing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of suspension stability of weighted materials, lack of clay-free high-temperature polymer filtrate reducers, etc. The effect of alleviating water resources dependence, low solid phase intrusion, and low cleaning requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

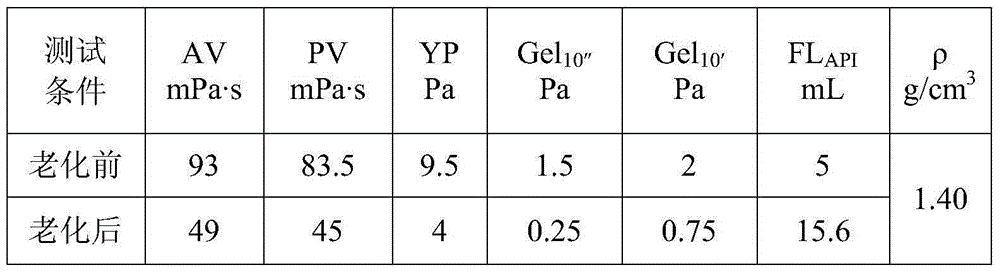

Examples

Embodiment 1

[0036] Take 300 kilograms of fresh water, add 130 kilograms of calcium chloride, fully dissolve, then add 1.6 kilograms of diammonium quaternary ammonium salt, 0.1 kilograms of alkylphenol polyoxyethylene ether OP-10, 1.1 kilograms of sodium sulfite, after being dissolved, continue to add 0.1 1 kg of modified cellulose, 2.1 kg of high temperature resistant modified starch fluid loss reducer, 1 kg of sulfonated asphalt, 1.5 kg of siloxane polyoxyethylene ether, after fully stirring, add 3 kg of graded calcium carbonate , stir well.

Embodiment 2

[0038] Take 300 kilograms of fresh water, add 252 kilograms of calcium chloride, fully dissolve, then add 1.4 kilograms of diammonium quaternary ammonium salt, 0.15 kilograms of alkylphenol polyoxyethylene ether OP-10, 0.9 kilograms of sodium sulfite, after being dissolved, continue to add 0.3 1 kg of modified cellulose, 1.9 kg of high temperature resistant modified starch fluid loss reducer, 1.5 kg of sulfonated asphalt, 1 kg of siloxane polyoxyethylene ether, after fully stirring, add 5 kg of graded calcium carbonate , stir well.

Embodiment 3

[0040] Take 300 kilograms of fresh water, add 190 kilograms of calcium chloride, fully dissolve, then add 1.5 kilograms of diammonium quaternary ammonium salt, 0.12 kilograms of alkylphenol polyoxyethylene ether OP-10, 1.0 kilograms of sodium sulfite, after dissolving, continue to add 0.2 1 kg of modified cellulose, 2.0 kg of high temperature resistant modified starch fluid loss reducer, 1.2 kg of sulfonated asphalt, 1.2 kg of siloxane polyoxyethylene ether, after fully stirring, add 4 kg of graded calcium carbonate , stir well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com