Graphite negative electrode material of lithium-ion battery and preparation method of graphite negative electrode material

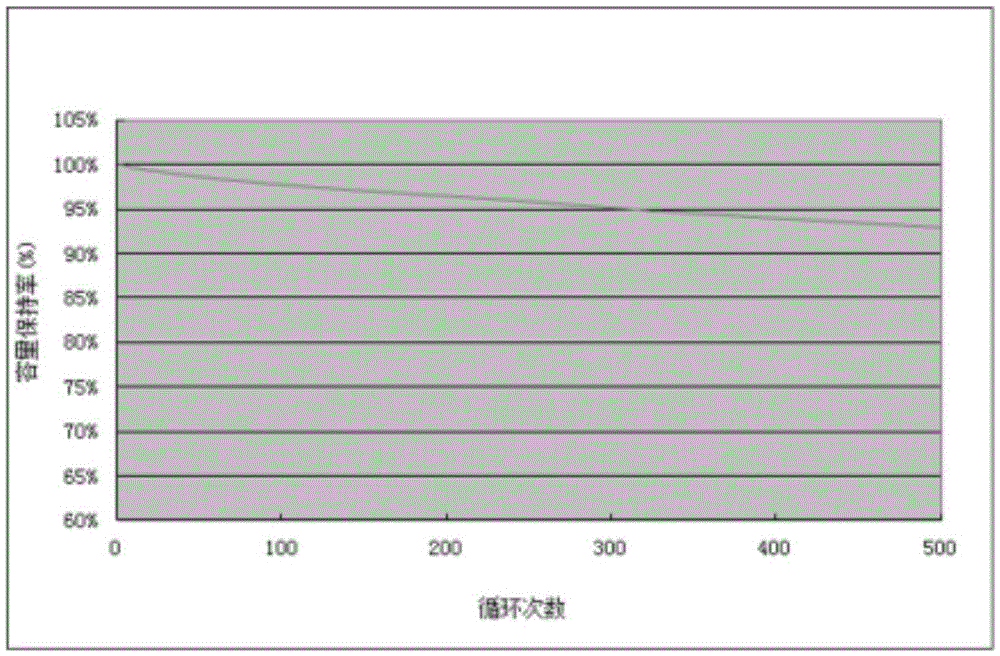

A lithium-ion battery, graphite anode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large irreversible capacity of the first charge and discharge of the battery, large specific surface area of modified materials, low first efficiency, etc., and achieve the first irreversible Effects of small capacity, high discharge capacity and first-time efficiency, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

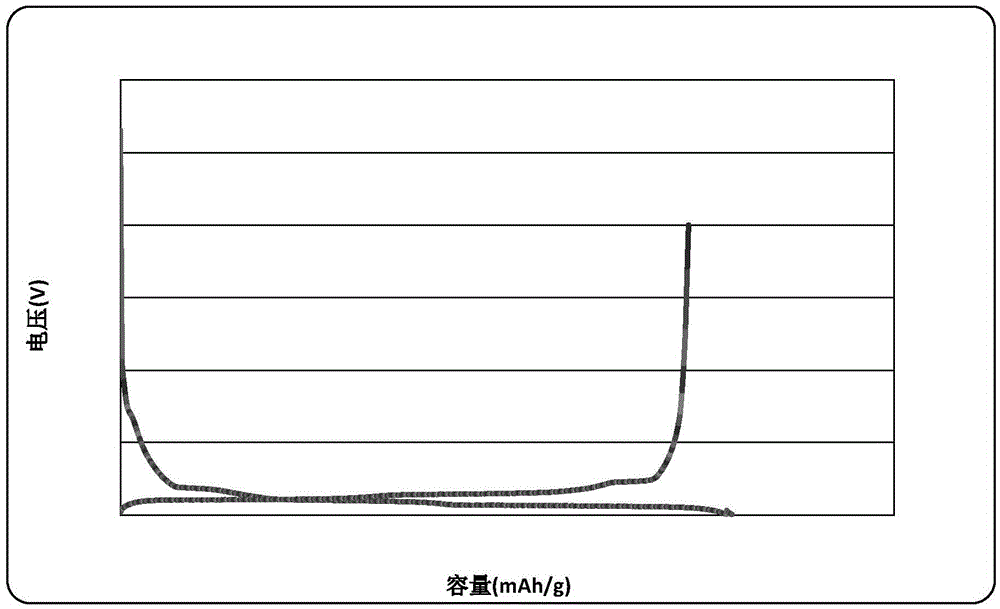

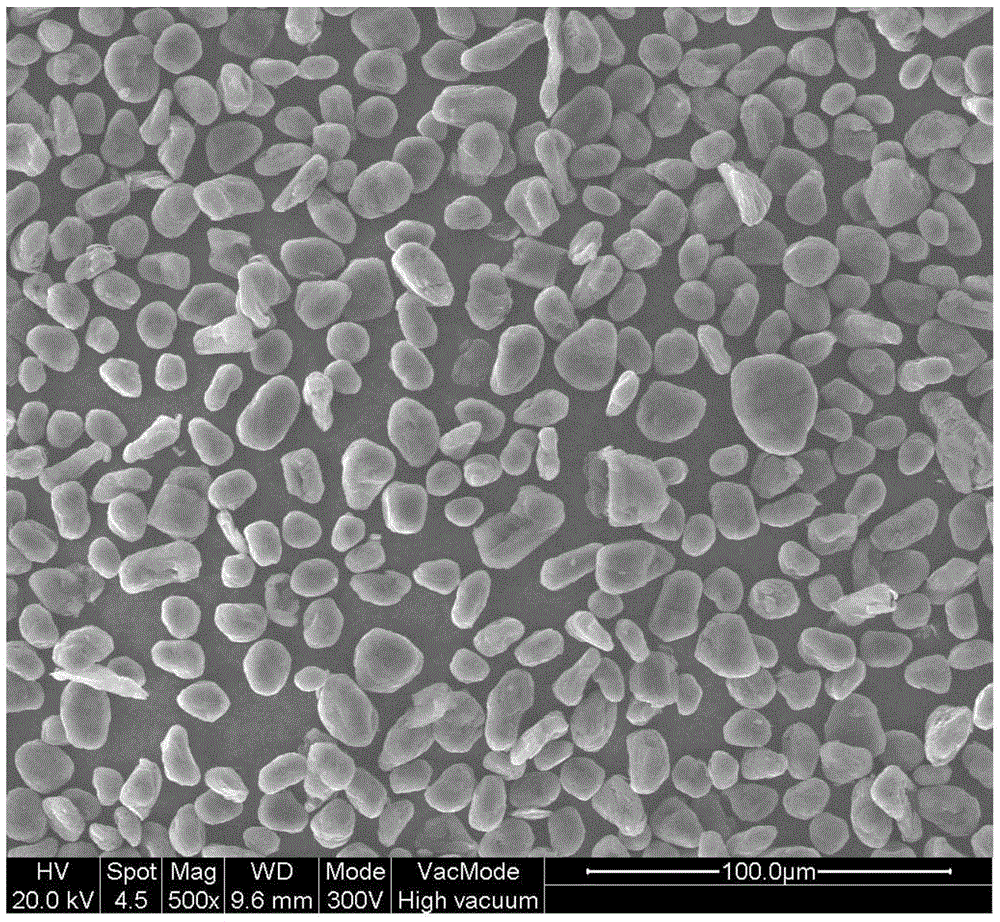

[0029] Weigh 19.2Kg of the main raw material A spherical natural graphite, the particle size D50 is 16.2μm, the carbon content is 99.98%, and the tap density is 1.04g / cm 3 , specific surface area 6.9m 2 / g; Weigh 0.8Kg of auxiliary raw material B petroleum asphalt, the particle size D50 is 5.0μm, the softening point is 252°C, and the coking value is 70.2%. After the completion, vacuum carbonization treatment is carried out, the vacuum degree is -0.09MPa, and the final temperature is 1300°C. After that, the reaction product is cooled to room temperature to obtain amorphous carbon-coated natural graphite, and then sieved through a 270-mesh vibrating sieve to obtain the undersize It is graphite anode material for lithium ion battery, its particle size D50 is 16.7 microns, and its tap density is 1.10g / cm 3 , specific surface area 3.0m 2 / g; carbon content 99.97%, half-cell capacity 366.9mAh / g, initial efficiency 93.2%.

[0030] The types and amounts of each raw material in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com