Experimental device capable of realizing absorption and regeneration combination based on wetted wall tower, and regeneration tower

An experimental device and wet wall tower technology, applied in mixers, fluid mixers, transportation and packaging, etc., can solve the problems of reduced reaction rate, small mass transfer coefficient of absorption liquid, and no heat exchange area in bubbling reactors , to achieve the effect of guaranteed regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

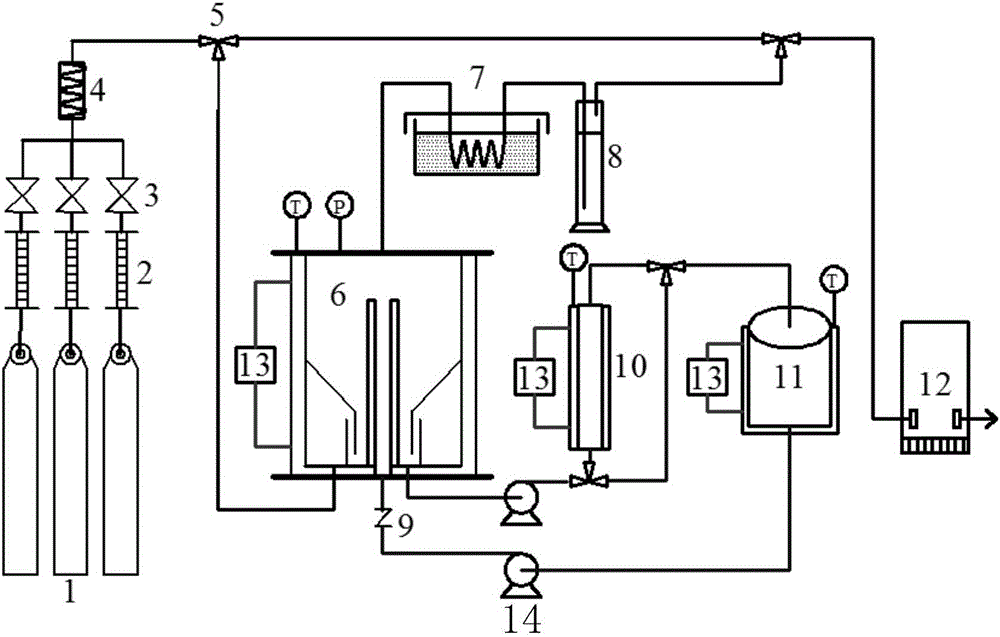

[0060]The invention provides an experimental device for realizing the combination of absorption and regeneration based on a wetted wall tower, the structure of which is as follows figure 1 shown, including:

[0061] Gas cylinder 1; mass flow meter 2; valve 3; gas mixer 4; tee 5; wetted wall tower 6; ice bath device 7; absorption bottle 8; check valve 9; regeneration tower 10; liquid storage tank 11; Gas analyzer 12; water bath device 13; peristaltic pump 14.

[0062] There are three gas cylinders 1, which are respectively filled with air, nitrogen and harmful gases (nitrogen oxides, sulfur oxides or carbon dioxide).

[0063] The inlet of the gas mixer 4 is connected to three branches, and each branch is connected to the valve 3, the mass flow meter 2, and the gas cylinder 1 in sequence from the inlet of the gas mixer 4, and the outlet of the gas mixer 4 is connected to the tee 5 ; One outlet of the tee 5 enters the wetted wall tower 6, and the other outlet directly enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com