Diesel engine particulate matter catcher regenerative burner and oil-injecting combustion-supporting compound regenerative system

A particle trap and diesel engine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of difficult control, burning loss, poor ignition reliability of the starter, etc., and achieve the effect of accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

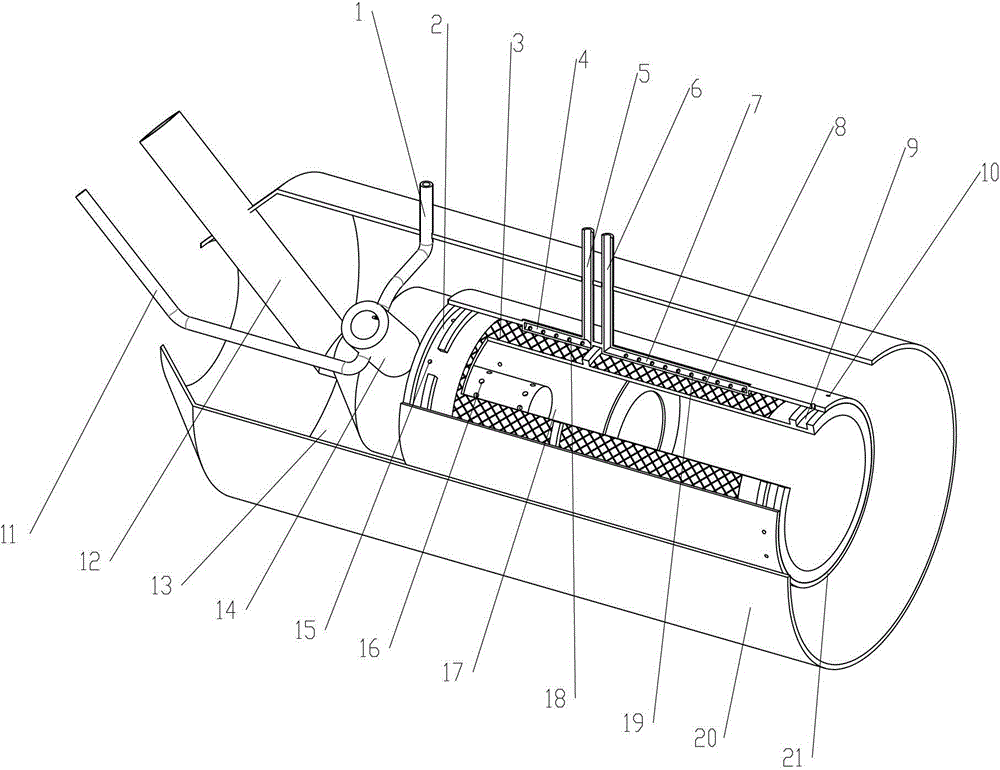

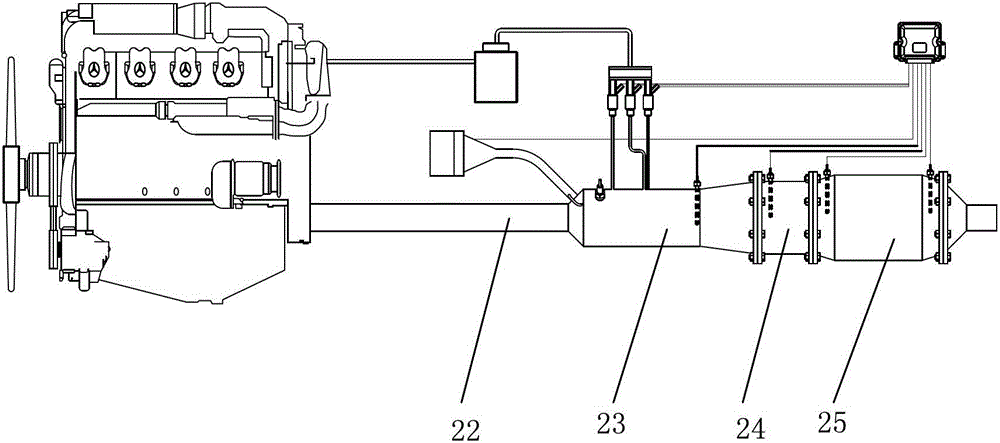

[0029] A schematic diagram of a regeneration starter of a diesel engine particulate matter trap according to the present invention is as follows figure 1As shown, it includes an inner barrel 21, an outer barrel 20, an air intake system, a glow plug seat 14, a primary oil supply system, a secondary oil supply system, and a tertiary oil supply system. The inner barrel 21 is concentrically fixed in the outer barrel 20 through supports. , the two ends of the outer barrel 20 are gas outlets respectively, one end of the inner barrel 21 is closed, the other end is open and opposite to the gas outlet of the outer barrel, the inner cavity of the inner barrel 21 is used as the combustion chamber 17, and the combustion The chamber is the chamber where the fuel burns. The space between the outer tub 20 and the inner tub 21 is used as the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com