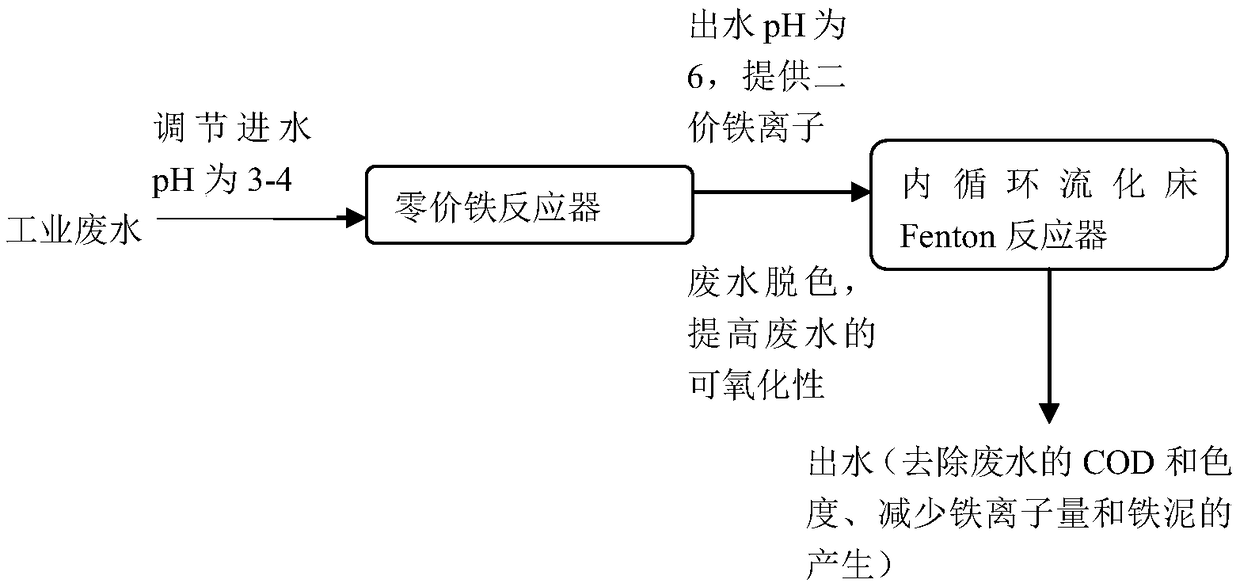

Industrial wastewater treatment process of zero-valent iron internal electrolysis coupled internal circulating fluidized bed Fenton

A technology of industrial wastewater and treatment process, applied in the direction of oxidized water/sewage treatment, special compound water treatment, water/sewage treatment, etc., can solve the problem of low COD removal of wastewater, acid-base adjustment, and regular slag discharge without maximizing the utilization rate of chemicals and other problems, to achieve the effect of eliminating the generation of iron sludge, realizing regeneration and reuse, and improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

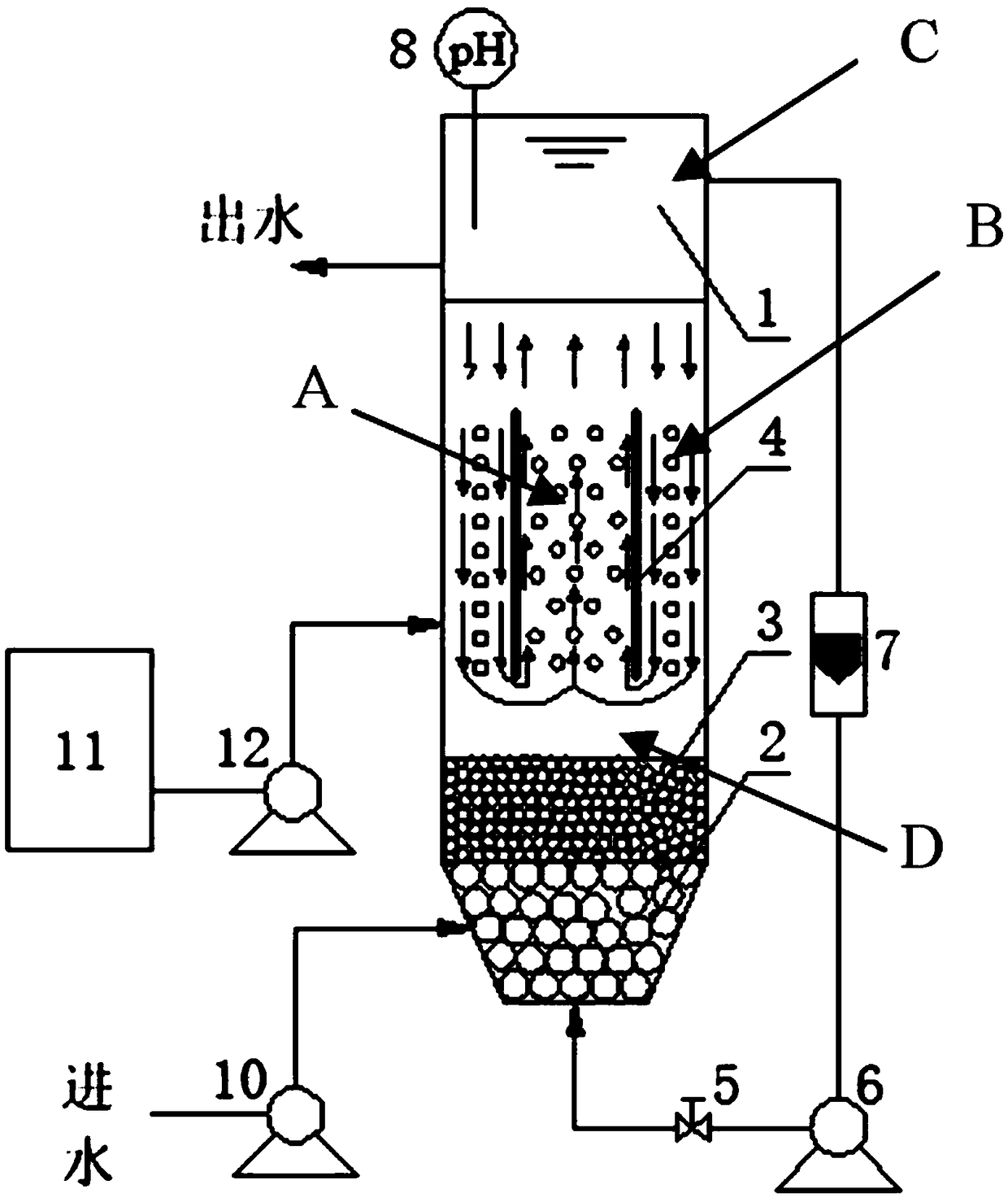

[0033] A kind of internal circulation fluidized bed Fenton reactor, structure such as figure 2As shown, the main body of the reactor is cylindrical, and the lower part is provided with a conical settling hopper. The side wall of the settling hopper is connected with the water inlet pipeline. A hydrogen peroxide pump 10 is arranged on the water inlet pipeline. The bottom of the settling hopper is connected with the return pipeline. The other end of the road is connected with the top side wall of the reactor main body 1 . A circulation pump 6 is provided on the return pipeline, a valve 5 is provided between the circulation pump 6 and the settling bucket, and a flow meter 7 is provided on the outlet pipeline of the circulation pump 6 . The device also includes a sodium hydroxide solution storage tank 11, which is connected to the fluidized bed reactor 1 through a sodium hydroxide solution pump 12. The liquid inlet of the sodium hydroxide solution is arranged in the middle part ...

Embodiment 2

[0040] In this example, the nitrobenzene production wastewater (COD 4000 mg / L-5000 mg / L, nitrobenzene concentration 200 mg / L, pH=3.5) requires the removal rate of nitrobenzene to reach 85%, and the removal rate of COD to reach 80% .

[0041] A kind of industrial wastewater treatment process of zero-valent iron internal electrolysis coupling internal circulating fluidized bed Fenton, the specific scheme and the equipment adopted are the same as embodiment 1, and the steps are as follows:

[0042] (1) For zero-valent iron, scrap iron chips (with a carbon content of 1%) are selected, the dosage is 5% of the mass ratio of wastewater, the reaction time is 2 hours, and the pH of the effluent is 6;

[0043] (2) In the reactor main body of the internal circulating fluidized bed Fenton reactor, the carrier above the glass beads is quartz sand of 80g / L, particle diameter 0.2mm;

[0044] (3) keep the residence time in the reactor main body (hereinafter referred to as fluidized bed) as 2...

Embodiment 3

[0051] In this embodiment, pharmaceutical wastewater (COD ~ 3000 mg / L, nitrobenzene concentration 150 mg / L, pH = 4.0) is used as the wastewater treatment for illustration.

[0052] A kind of industrial wastewater treatment process of zero-valent iron internal electrolysis coupling internal circulating fluidized bed Fenton, the specific scheme and the equipment adopted are the same as embodiment 1, and the steps are as follows:

[0053] (1) For zero-valent iron, scrap iron chips (with a carbon content of 1%) are selected, the dosage is 1% of the mass ratio of wastewater, the reaction time is 2 hours, and the pH of the effluent is 6.5;

[0054] (2) Add 80g / L of activated carbon in the fluidized bed, with a particle size of 0.6mm;

[0055] (3) keep the residence time in the fluidized bed as 2h;

[0056] (4) Control the ascending flow rate of the liquid in the fluidized bed to be 30m / h by returning the water outlet part from the top of the fluidized bed to the bottom, and add hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com