A kind of LED low temperature sealing glass containing p2o5

A technology of sealing glass and P2O5, which is applied in the field of sealing glass, can solve problems such as low-temperature sealing and rapid sintering, unsolved environmental protection problems, poor thermal stability, etc., and achieve the effect of low cost, low price and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

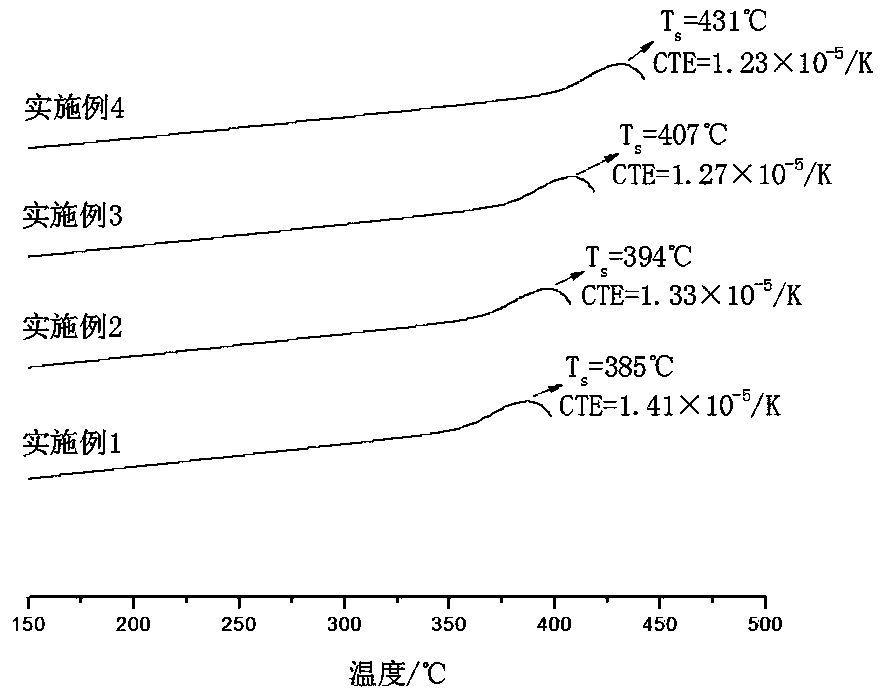

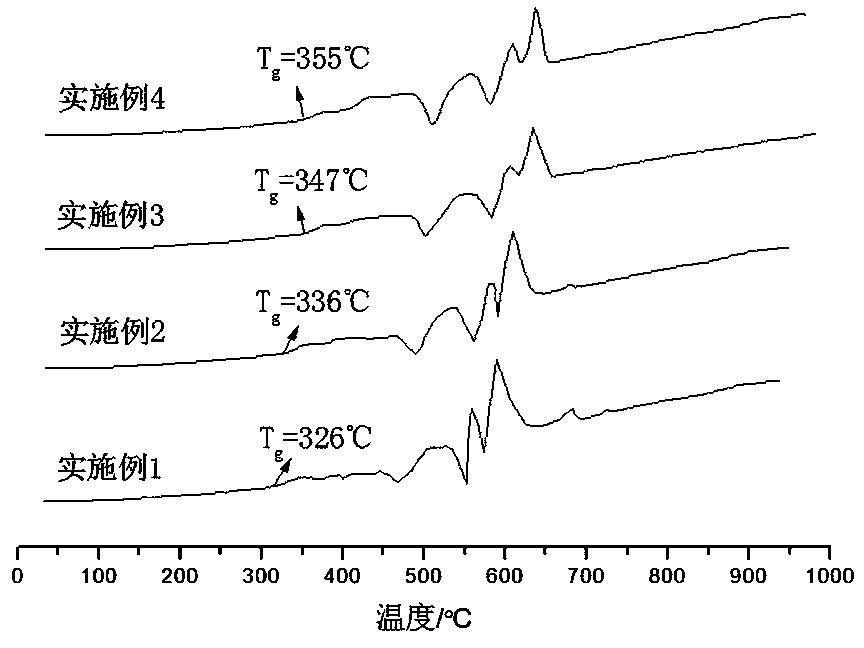

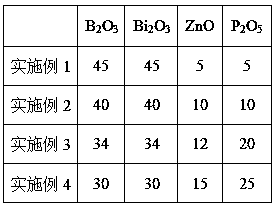

[0031] Embodiment 1: Preparation and sealing of materials

[0032] According to the proportioning of each component of embodiment 1 in table 1, take a certain amount of analytically pure raw material (B 2 o 3 、 Bi 2 o 3 , ZnO, P 2 o 5 ), use a planetary ball mill for 24 hours to mix evenly; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, heat it to 900°C at 3°C / min, and keep it warm for 1 hour; then, take out the crucible, Pour the melt into deionized water for rapid cooling, and dry to obtain fragments of glass melt; grind and pass through a 100-mesh sieve to obtain glass powder. Mix glass powder with polyvinyl alcohol, fish oil, ethanol and toluene (80%, 2%, 1%, 10%, 7% by weight) to form a slurry, and disperse evenly in a ball mill; tape casting, natural Dry, then cut into the embryo body of the desired shape; place the embryo body on the part to be sealed, heat up at a rate of 2°C / min in an electric furna...

Embodiment 2

[0033] Embodiment 2: Preparation and sealing of materials

[0034] According to the proportioning of each component of embodiment 2 in table 1, take a certain amount of analytically pure raw material (B 2 o 3 、 Bi 2 o 3 , ZnO, P 2 o 5), use a planetary ball mill for 24 hours to mix evenly; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, heat it to 900°C at 3°C / min, and keep it warm for 1 hour; then, take out the crucible, Pour the melt into deionized water for rapid cooling, and dry to obtain fragments of glass melt; grind and pass through a 100-mesh sieve to obtain glass powder. Mix glass powder with methylcellulose, polyvinyl alcohol, n-butanol and acetone (82%, 2%, 2%, 8%, 6% by weight) to form a slurry, and disperse evenly in a ball mill; Stretching, drying naturally, and then cutting the embryo body into the desired shape; placing the embryo body on the part to be sealed, raising the temperature in an el...

Embodiment 3

[0035] Embodiment 3: Preparation and sealing of materials

[0036] According to the proportioning of each component of embodiment 3 in table 1, take a certain amount of analytically pure raw material (B 2 o 3 、 Bi 2 o 3 , ZnO, P 2 o 5 ), use a planetary ball mill for 24 hours to mix evenly; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, heat it to 900°C at 3°C / min, and keep it warm for 1 hour; then, take out the crucible, Pour the melt into deionized water for rapid cooling, and dry to obtain fragments of glass melt; grind and pass through a 100-mesh sieve to obtain glass powder. Mix glass powder with epoxy resin, polyacrylamide, isopropanol and toluene (84%, 1.5%, 0.5%, 9%, 5% by weight) to form a slurry, and disperse evenly in a ball mill; casting Forming, drying naturally, and then cutting into the embryo body of the desired shape; place the embryo body on the part to be sealed, heat up at a rate of 2°C / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Glass transition point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com