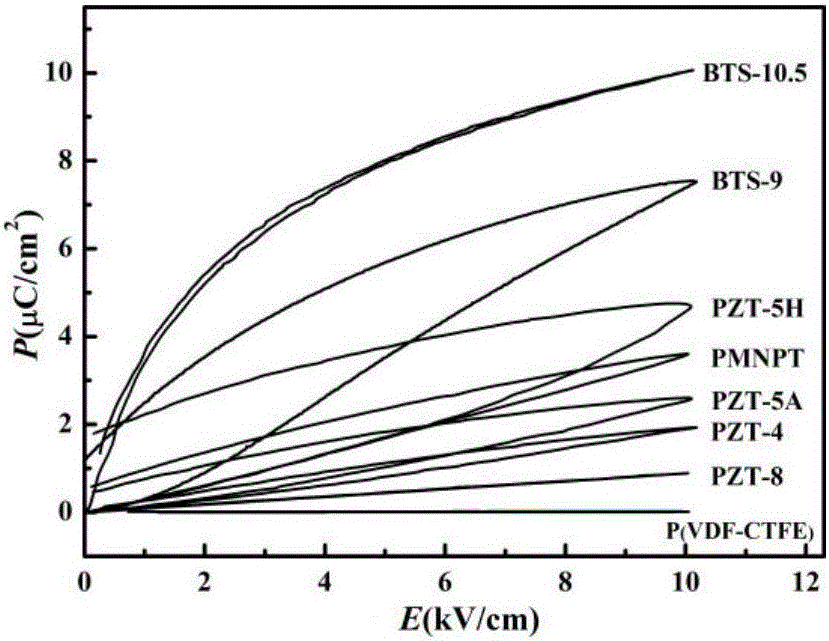

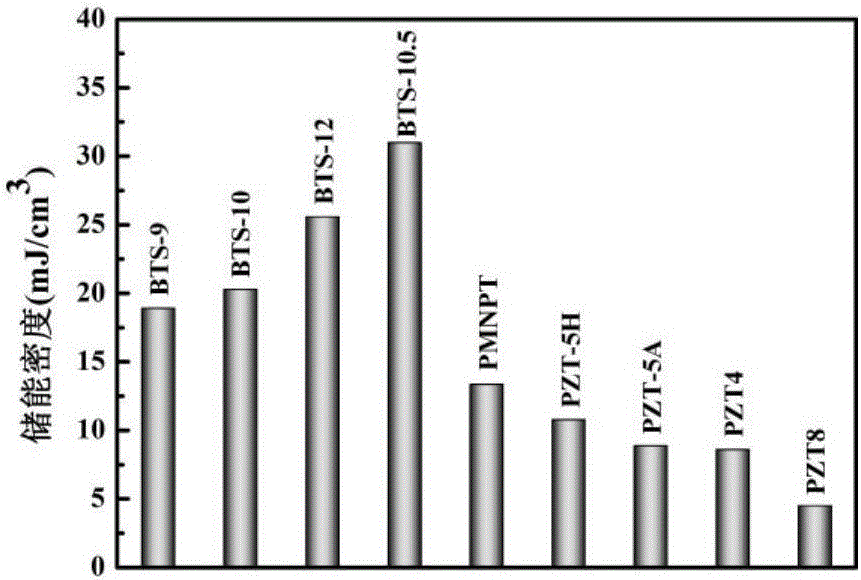

Dielectric ceramic high in energy density in low electric fields and preparing method thereof

A technology of high energy density and dielectric ceramics, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, circuits, etc., to achieve the effect of simple composition and process steps, high permittivity, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a dielectric ceramic with low electric field and high energy density, comprising the following steps:

[0030] (1) According to chemical formula (1-x) BaTiO 3 -xBaSnO 3 The proportion of each element in the weighing raw material BaCO 3 、TiO 2 and SnO 2 , where 0.03≤x≤0.15;

[0031] (2) Mix the weighed raw materials and put them into a ball mill jar, add the ball milling solvent anhydrous ethanol and agate balls, mill for 4 hours, the ball milling speed is 40-50 rpm, and then put the mixture in an oven at 80°C Dry for 3 hours, then put it into a mortar and grind, and then pass through a 60-mesh sieve to obtain powder;

[0032] (3) Put the powder obtained in step (2) into the crucible, compact it, and cover it; pre-fire it in a muffle furnace at 1350°C, keep it warm for 4 hours, cool it down to room temperature naturally, and take it out of the furnace to obtain the pre-fired powder ;

[0033] (4) Grind the calcined powder obtained in step (3...

Embodiment 1

[0043] (1) According to chemical formula (1-x) BaTiO 3-xBaSnO 3 The proportion of each element in the weighing raw material BaCO 3 、TiO 2 and SnO 2 , where x=0.03;

[0044] (2) Mix the weighed raw materials and put them into a ball mill jar, add ball milling solvent anhydrous ethanol and agate balls, mill for 4 hours, and the ball milling speed is 40 rpm, then put the mixture into an oven for drying at 80°C 3 hours, then put into a mortar and grind, then pass through a 60-mesh sieve to obtain powder;

[0045] (3) Put the powder obtained in step (2) into the crucible, compact it, and cover it; pre-fire it in a muffle furnace at 1350°C, keep it warm for 4 hours, cool it down to room temperature naturally, and take it out of the furnace to obtain the pre-fired powder ;

[0046] (4) Grind the calcined powder obtained in step (3) into a fine powder in a mortar, put it into a ball mill jar, add ball milling medium absolute ethanol, and carry out secondary ball milling at a spe...

Embodiment 2

[0053] (1) According to chemical formula (1-x) BaTiO 3 -xBaSnO 3 The proportion of each element in the weighing raw material BaCO 3 、TiO 2 and SnO 2 , where x=0.09;

[0054] (2) Mix the weighed raw materials and put them into a ball mill jar, add ball milling solvent anhydrous ethanol and agate balls, mill for 4 hours, and the ball milling speed is 45 rpm, then put the mixture into an oven for drying at 80°C 3 hours, then put into a mortar and grind, then pass through a 60-mesh sieve to obtain powder;

[0055] (3) Put the powder obtained in step (2) into the crucible, compact it, and cover it; pre-fire it in a muffle furnace at 1350°C, keep it warm for 4 hours, cool it down to room temperature naturally, and take it out of the furnace to obtain the pre-fired powder ;

[0056] (4) Grind the calcined powder obtained in step (3) into a fine powder in a mortar, put it into a ball mill jar, add ball milling medium absolute ethanol, and carry out secondary ball milling at a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com