Porous organic polymer framework material and preparation method and application thereof

A skeleton material and polymer technology, applied in the field of porous organic polymer materials and their preparation, can solve the problems of increasing the preparation cost of porous polymers, and achieve the effects of high atom economy, wide applicability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

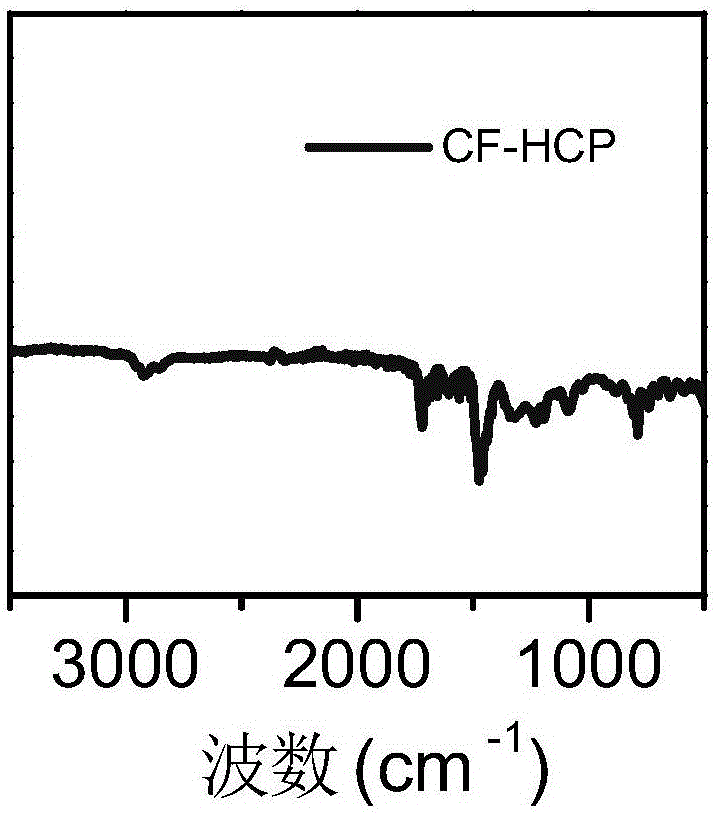

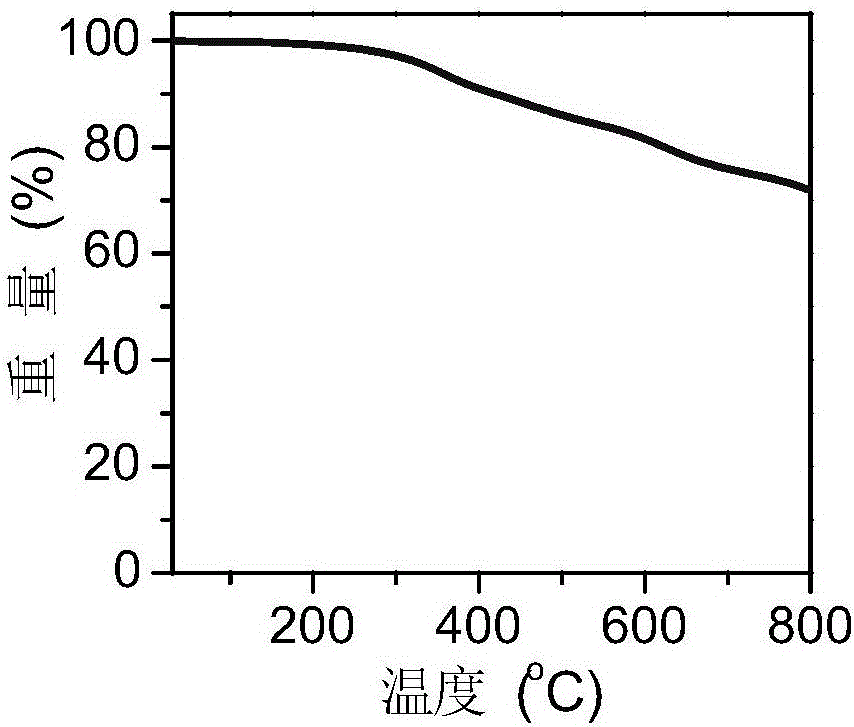

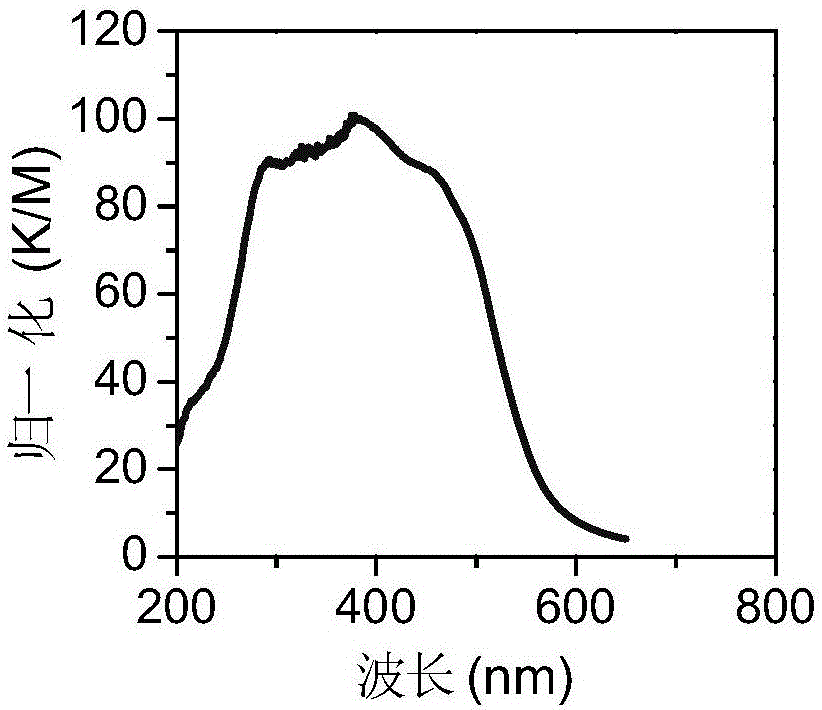

[0031] Under the protection of an inert gas, 2,7-bis-(nitrogen-carbazolyl)-9 fluorenone (108.5mg, 0.2mmol), dimethylformal (70.8μL, 0.8mmol) and FeCl 3 (0.13g, 0.8mmol) was placed in a 50mL round bottom flask, 4mL of 1,2-dichloroethane was added to it, and the mixture was stirred at 80°C for 24h. After the reaction was completed, the system was cooled to room temperature, and the solid formed by the reaction was filtered, washed with 10-30 ml of methanol, water, dichloromethane, and acetone in sequence, and Soxhlet extracted with acetone and methanol for 12 hours respectively. The solid product after Soxhlet extraction was vacuum-dried to obtain a brown porous organic polymer framework material.

[0032] Use a specific surface area and pore size analyzer (JW-BK 132F) to detect its specific surface area and pore size distribution, and the measured specific surface area is 1217m 2 g -1 . The pore volume is 0.92cm 3 g -1 . The pore size distribution is 0.6, 0.8, 1.1, 2.1 nm...

Embodiment 2

[0034] Under the protection of inert gas, 2,7-bis-(nitrogen-carbazolyl)-9 fluorenone (108.5mg, 0.2mmol), dimethylformal (35.4μL, 0.4mmol) and FeCl 3 (0.065g, 0.4mmol) was placed in a 50mL round bottom flask, 4mL of 1,2-dichloroethane was added to it, and the mixture was stirred at 80°C for 24h. After the reaction was completed, the system was cooled to room temperature, and the solid formed by the reaction was filtered, washed with 10-30 ml of methanol, water, dichloromethane, and acetone in sequence, and Soxhlet extracted with acetone and methanol for 12 hours respectively. The solid product after Soxhlet extraction was vacuum-dried to obtain a brown porous organic polymer framework material.

[0035] Use the specific surface area and pore size analyzer (JW-BK 132F) to detect the specific surface area and pore size distribution, and the measured specific surface area is 735m 2 g -1 . Pore volume is 0.50cm 3 g -1 . The pore size distribution is 0.6, 1.0, 1.2, 2.3 nm. ...

Embodiment 3

[0037] Under the protection of inert gas, 2,7-bis-(nitrogen-carbazolyl)-9 fluorenone (108.5mg, 0.2mmol), dimethylformal (106.2μL, 1.2mmol) and FeCl 3(0.195g, 1.2mmol) was placed in a 50mL round bottom flask, 4mL of 1,2-dichloroethane was added to it, and the mixture was stirred at 80°C for 24h. After the reaction was completed, the system was cooled to room temperature, and the solid formed by the reaction was filtered, washed with 10-30 ml of methanol, water, dichloromethane, and acetone in sequence, and Soxhlet extracted with acetone and methanol for 12 hours respectively. The solid product after Soxhlet extraction was vacuum-dried to obtain a brown porous organic polymer framework material.

[0038] Use a specific surface area and pore size analyzer (JW-BK 132F) to detect its specific surface area and pore size distribution, and the measured specific surface area is 654m 2 g -1 . The pore volume is 0.48cm 3 g -1 . The pore size distribution is 0.5, 0.8, 1.1, 2.3 nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com