Photo-thermal dual-curing shielding glue and preparation method thereof

A dual-curing and heat-curing technology, applied in the field of chemical materials, can solve the problems of overflowing glue and incomplete curing, and achieve the effects of improving strength, drop resistance and high shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

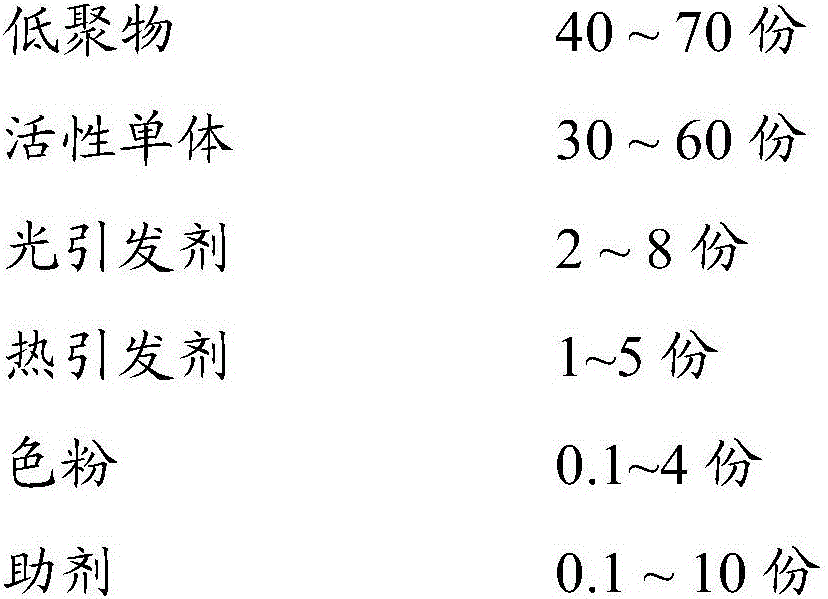

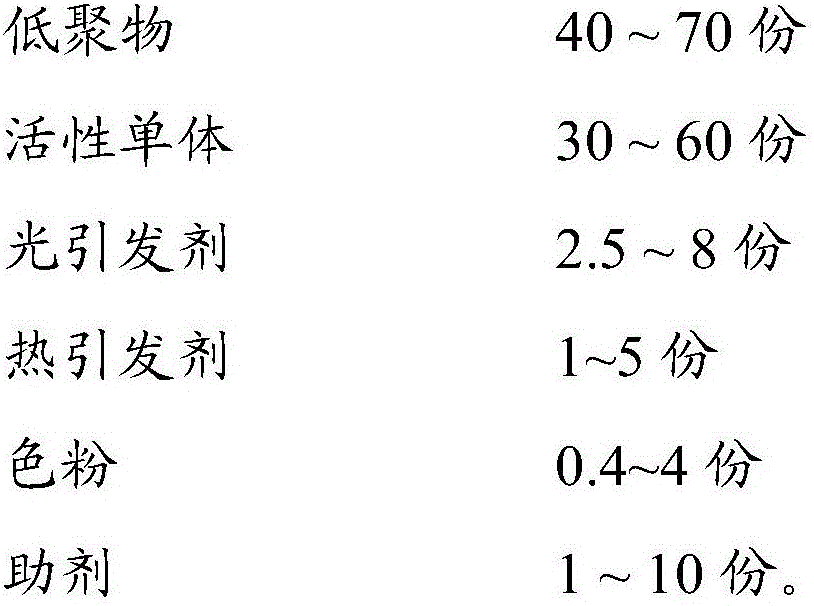

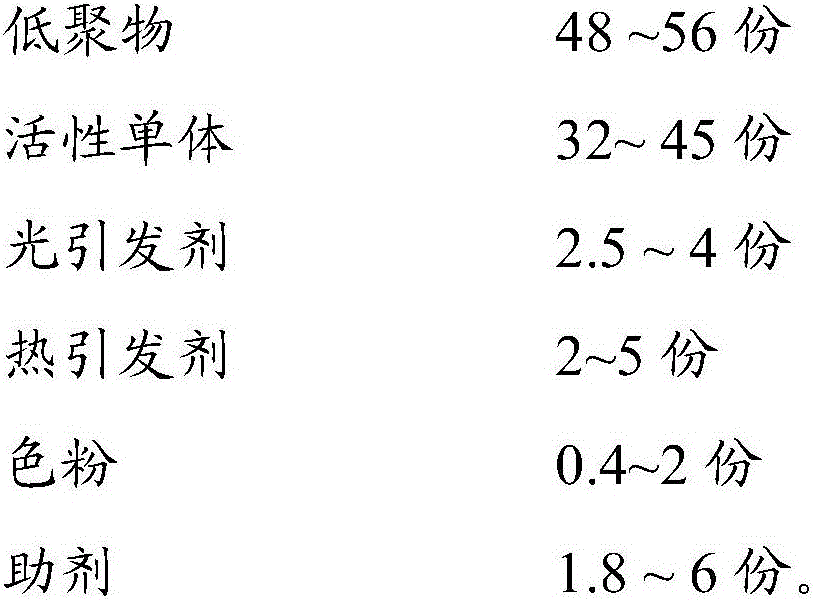

[0044] A photothermal dual curing masking glue prepared from raw materials:

[0045] Oligomers: 48.0 g in total.

[0047] Active monomer: 43.6 g in total.

[0048] The active monomer of monofunctional acrylate, isobornyl acrylate (IBOA) 24.2g,

[0049] Active monomer of polyfunctional acrylate, ditrimethylolpropane triacrylate 19.4g.

[0050] Photoinitiator: 3.9 g in total.

[0051] 3.9 g of 2-phenylbenzyl-2-dimethylamine-1-(4-morpholinebenzylphenyl)butanone.

[0052] Thermal initiator: 2.3 g in total.

[0053] 2.3 g of tert-butyl peroxy-2-ethylhexanoate.

[0054] Toner: 0.4g in total.

[0055] 0.4 g of carbon black.

[0056] Additives: 1.8g in total.

[0057] Adhesion promoter (2-hydroxyethyl methacrylate phosphate) 1.0g,

[0058] Defoamer (silicone defoamer, model BYK-066N) 0.3g,

[0059] Leveling agent (organic silicon leveling agent, the model is SIVEL 5525) 0.2g,

[0060] Dispersant (modified polydimethylsiloxane, model is BYK-160...

Embodiment 2

[0074] A photothermal dual curing masking glue prepared from raw materials:

[0075] Oligomer: 50.0 g in total.

[0076] Polyester acrylate 50.0 g.

[0077] Active monomer: a total of 41g.

[0078] The active monomer of monofunctional acrylate, isobornyl acrylate (IBOA) 18.2g,

[0079] Active monomer of difunctional acrylate, 1,6-hexanediol diacrylate 13.8g

[0080] Active monomer of multifunctional acrylate, dipentaerythritol pentaacrylate 9.0g.

[0081] Photoinitiator: 3.9 g in total.

[0082] 3.9 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide.

[0083] Thermal initiator: 2.3 g in total.

[0084] Tert-butyl peroxybenzoate 2.3g.

[0085] Toner powder: 0.5g in total.

[0086] 0.5 g of carbon black.

[0087] Additives: 2.3g in total.

[0088] Adhesion promoter (2-hydroxyethyl methacrylate phosphate) 1.0g,

[0089] Adhesion promoter (γ-methacryloxypropyltriethoxysilane) 0.5g,

[0090] Defoamer (silicone defoamer, model BYK-066N) 0.3g,

[0091] Leveling agent (o...

Embodiment 3

[0106] A photothermal dual curing masking glue prepared from raw materials:

[0107] Oligomers: 55.6 g in total.

[0108] Pure acrylate 55.6g.

[0109] Active monomer: 32.1 g in total.

[0110] The active monomer of monofunctional acrylate, isobornyl acrylate (IBOA) 8.3g,

[0111] Active monomer of difunctional acrylate, tripropylene glycol diacrylate 11.8g,

[0112] Active monomer of multifunctional acrylate, 12.0 g of dipentaerythritol pentaacrylate.

[0113] Photoinitiator: 2.5g in total.

[0114] 2.5 g of bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide.

[0115] Thermal initiator: 2.5 g in total.

[0116] Tert-butyl peroxybenzoate 2.5g.

[0117] Toner: 2g in total.

[0118] Carbon black 2g.

[0119] Additives: 5.3g in total.

[0120] Adhesion promoter (2-hydroxyethyl methacrylate phosphate) 1.6g,

[0121] Adhesion promoter (multifunctional thiol compound PE-1) 2.5g,

[0122] Defoamer (silicone defoamer, model BYK-066N) 0.4g,

[0123] Leveling agent (organic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com