Preparation process for high-temperature-resistant high-thermal-conductivity insulating paint

A preparation process and technology of insulating coatings, applied in anti-corrosion coatings, fire-retardant coatings, organic insulators, etc., can solve the problems of low working temperature, insufficient adhesion to wear-resistant substrates, and narrow application range, and improve adhesion and bonding force. Strong, not easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

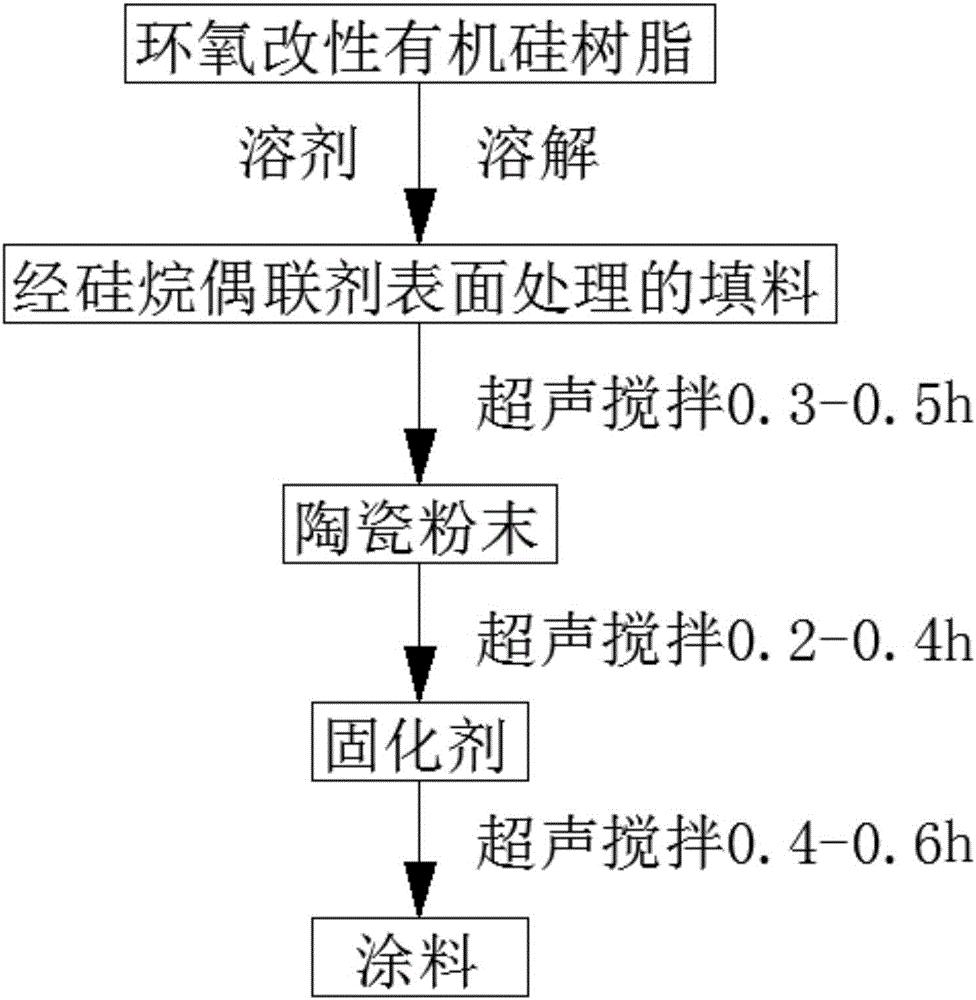

Method used

Image

Examples

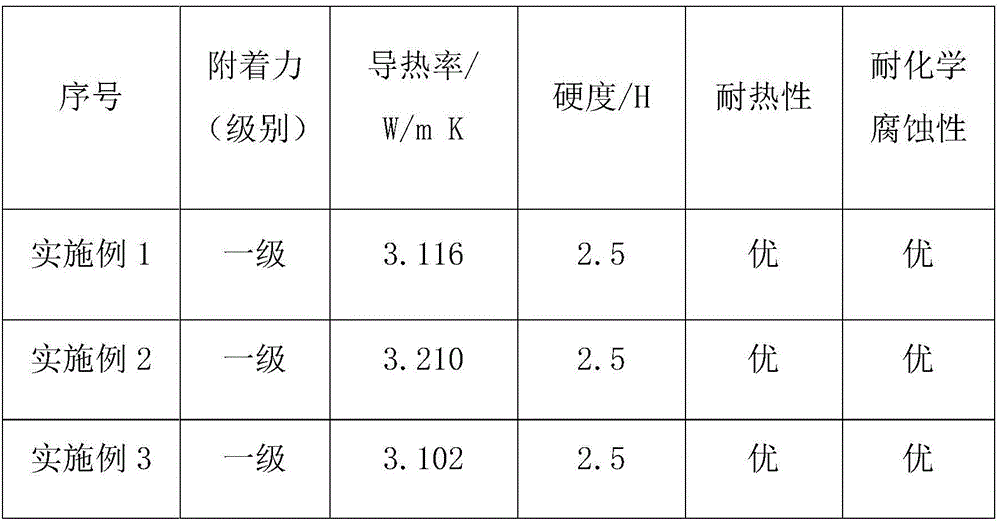

Embodiment 1

[0028] A kind of high temperature resistant high thermal conductivity insulating coating, described coating is made up of the raw material of following mass percent: epoxy modified organosilicon resin 12%, solvent 48%, silane coupling agent 0.7%, filler 39%, curing agent 0.2%, 0.06% of ceramic powder and 0.04% of nano-diamond, wherein the epoxy-modified silicone resin is specifically epoxy-modified silicone resin HG-41.

[0029] In this embodiment, the solvent includes propylene glycol methyl ether acetate, xylene and butyl acetate, and their mass ratio is 4:3:3.

[0030] In this embodiment, the filler includes silicon nitride, aluminum oxide, magnesium oxide and boron nitride, and the proportions of the above components in the filler are 70% for silicon nitride, 15% for aluminum oxide, and 10% for magnesium oxide. % and boron nitride 5%.

[0031] In this embodiment, the particle diameters of silicon nitride, aluminum oxide, magnesium oxide and boron nitride are 300-10000 nm....

Embodiment 2

[0037]A kind of high temperature resistant high thermal conductivity insulating coating, described coating is made up of the raw material of following mass percent: epoxy modified organosilicon resin 15%, solvent 45%, silane coupling agent 0.7%, filler 39%, curing agent 0.2%, 0.05% of ceramic powder and 0.05% of nano-diamond, wherein the epoxy-modified silicone resin is specifically epoxy-modified silicone resin HG-41.

[0038] In this embodiment, the solvent includes propylene glycol methyl ether acetate, xylene and butyl acetate, and their mass ratio is 4:3:3.

[0039] In this embodiment, the filler includes silicon nitride, aluminum oxide, magnesium oxide and boron nitride, and the proportions of the above components in the filler are 75% for silicon nitride, 10% for aluminum oxide, and 10% for magnesium oxide. % and boron nitride 5%.

[0040] In this embodiment, the particle diameters of silicon nitride, aluminum oxide, magnesium oxide and boron nitride are 300-10000 nm. ...

Embodiment 3

[0046] A kind of high temperature resistant high thermal conductivity insulating coating, described coating is made up of the raw material of following mass percent: epoxy modified organosilicon resin 23%, solvent 35%, silane coupling agent 0.7%, filler 41%, curing agent 0.2%, 0.06% of ceramic powder and 0.04% of nano-diamond, wherein the epoxy-modified silicone resin is specifically epoxy-modified silicone resin HG-41.

[0047] In this embodiment, the solvent includes propylene glycol methyl ether acetate, xylene and butyl acetate, and their mass ratio is 4:3:3.

[0048] In this embodiment, the filler includes silicon nitride, aluminum oxide, magnesium oxide and boron nitride, and the proportions of the above components in the filler are 80% for silicon nitride, 8% for aluminum oxide, and 8% for magnesium oxide. % and boron nitride 4%.

[0049] In this embodiment, the particle diameters of silicon nitride, aluminum oxide, magnesium oxide and boron nitride are 300-10000 nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com