Shale inhibitor for drilling fluid and preparation method thereof

A technology for shale inhibitor and drilling fluid, applied in the field of petroleum drilling fluid, can solve the problems of complicated steps, many raw materials and high cost, and achieves the effects of good repeatability, difficult desorption and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Add 240g (0.4mol) polyetheramine M600 (Huntsman company) and 12g (0.2mol) acetic acid in the 500mL four-neck round-bottomed flask equipped with thermal device, temperature controller, water separator and stirrer, under nitrogen protection, heat Raise the temperature to 150° C., stir and react for 2 hours at a stirring speed of 150 r / min, and obtain the shale inhibitor for drilling fluid. The water vapor generated during the reaction was carried away by nitrogen flow. The product obtained from the reaction can be directly added to the drilling fluid as an inhibitor.

[0048] The synthesis route of shale inhibitor for drilling fluid is as follows:

[0049]

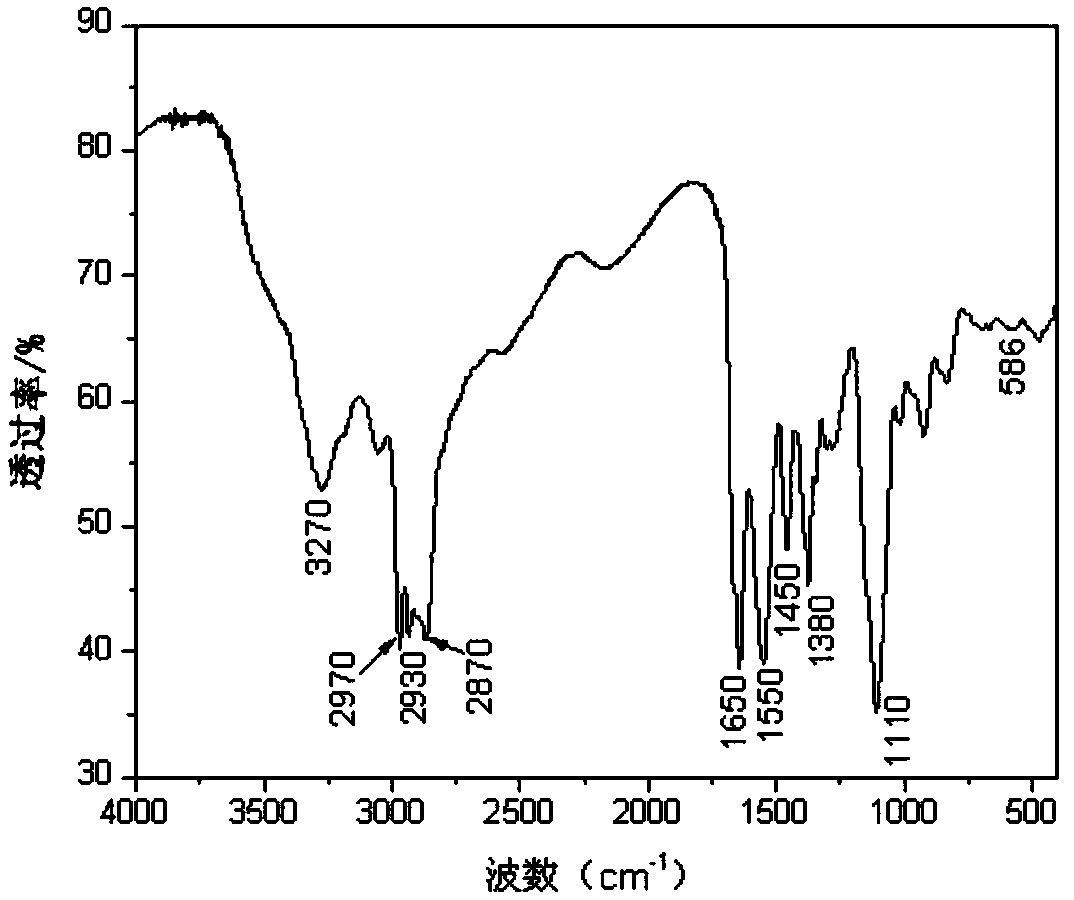

[0050] figure 1 Infrared spectrogram of the shale inhibitor for drilling fluid prepared for this example. Depend on figure 1 It can be seen that due to the formation of hydrogen bonds, there are two peaks in the N-H stretching vibration, which are 3270 cm -1 and 3050cm -1 , 2970cm -1 、2870cm -1 NH 3 The sy...

Embodiment 2

[0052] Add 176g (1mol) of polyoxyethylene diamine EDR176 (Huntsman Company) and 63g (0.5mol) of oxalic acid to a 500mL four-neck round-bottom flask equipped with a thermal device, temperature controller, water separator and stirrer, nitrogen protection , heated to 150°C, stirred and reacted for 5 hours, and the stirring rate was 150r / min, and the shale inhibitor for drilling fluid was obtained. The water vapor generated during the reaction was carried away by nitrogen flow. The product obtained from the reaction can be directly added to the drilling fluid as an inhibitor.

[0053] The synthesis route of shale inhibitor for drilling fluid is as follows:

[0054]

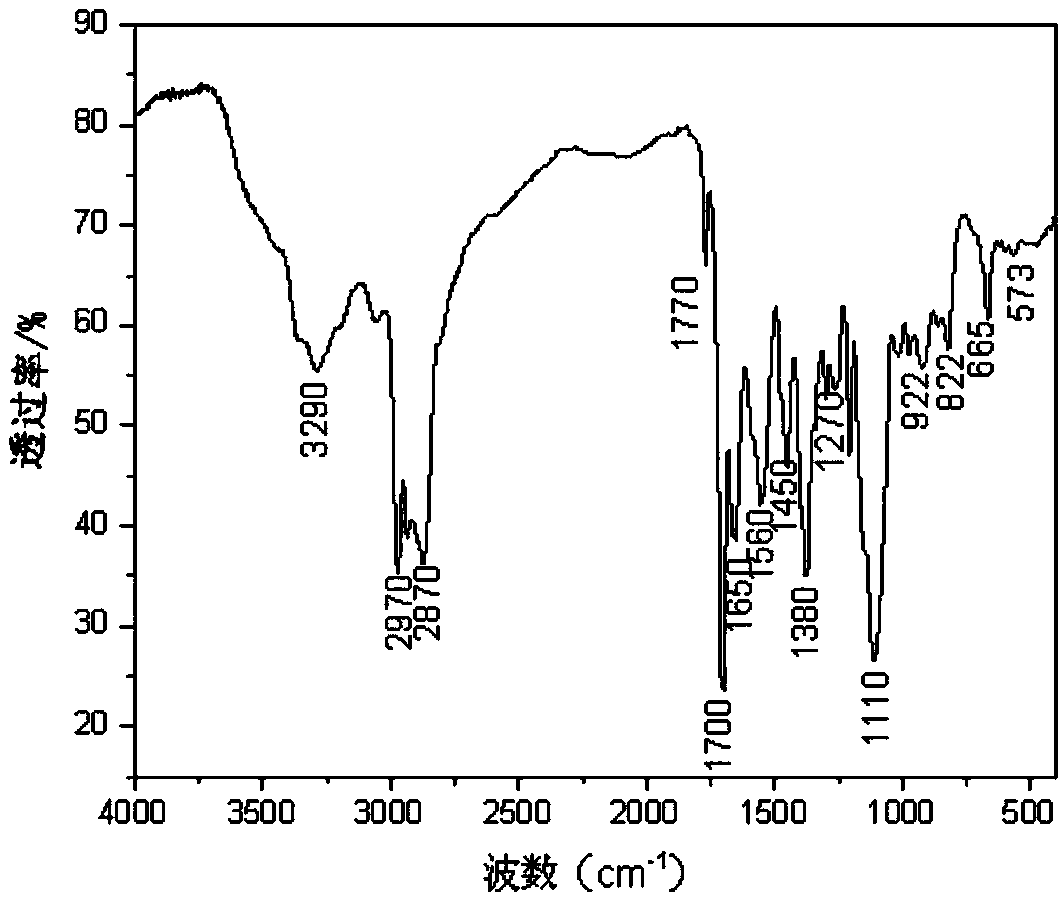

[0055] figure 2 Infrared spectrogram of the shale inhibitor for drilling fluid prepared for this example. Depend on figure 2 It can be seen that 3290cm -1 N-H stretching vibration absorption peak, 1650cm -1 It is C=O stretching vibration absorption peak (amide I peak), 1560cm -1 C-N-H bending vibration abs...

Embodiment 3

[0057] Add 215g (0.5mol) of polyoxypropylene diamine D-400 (Huntsman Company) and 29.5g (0.25mol) of butanediene into a 500mL four-necked round-bottomed flask equipped with a heating device, a temperature controller, a water separator and a stirrer. acid, under the protection of nitrogen, heated to 140°C, stirred for 8 hours, and the stirring rate was 300r / min, and the shale inhibitor for drilling fluid was obtained. The water vapor generated during the reaction was carried away by nitrogen flow. The product obtained from the reaction can be directly added to the drilling fluid as an inhibitor.

[0058] The synthesis route of shale inhibitor for drilling fluid is as follows:

[0059]

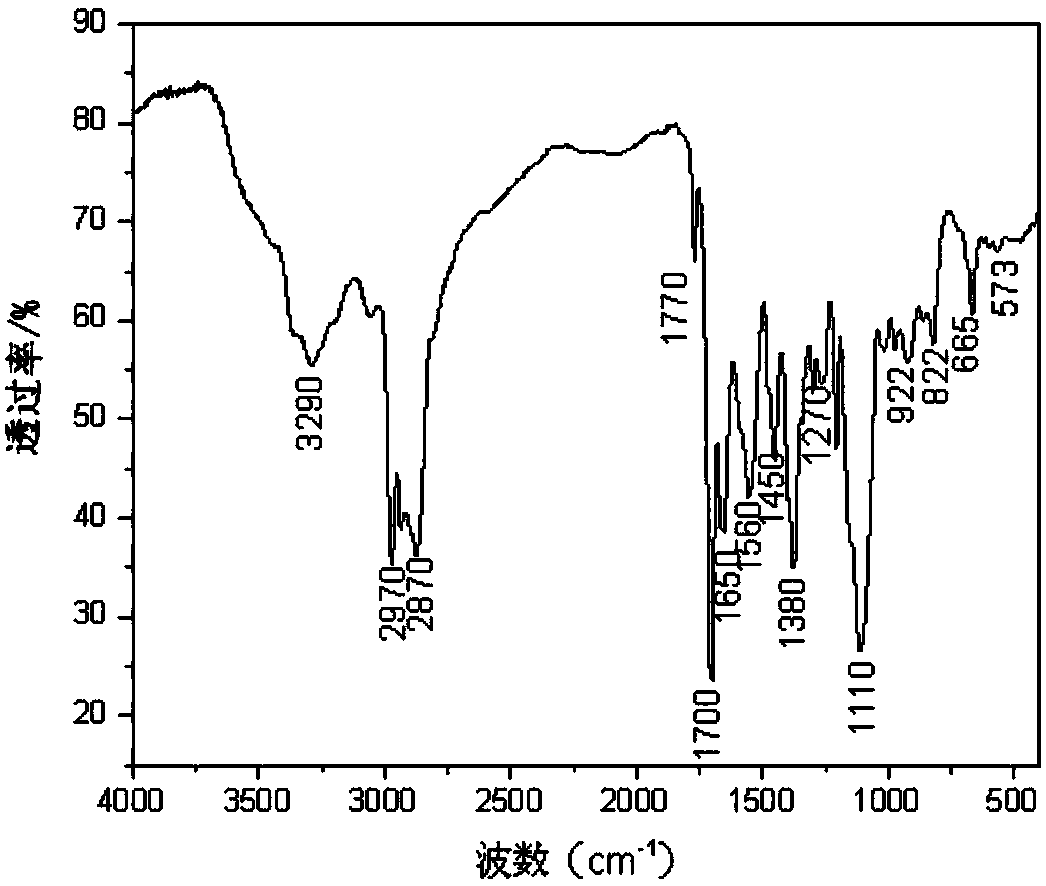

[0060] image 3 Infrared spectrogram of the shale inhibitor for drilling fluid prepared for this example. Depend on image 3 It can be seen that 3280cm -1 N-H stretching vibration absorption peak, 1700cm -1 It is C=O stretching vibration absorption peak (amide I peak), 1560cm -1 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com