A post-weld heat treatment method for improving the corrosion resistance of aluminum-lithium alloy electron beam welded joints

An electron beam welding and post-weld heat treatment technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as corrosion of aircraft structural materials, impact on aircraft service life, aircraft crashes, etc. The effect of refining the structure and grain, and the technical level is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step is to select the Al-Cu-Li alloy plate, first use the electron beam process to butt weld it, and then carry out solid solution treatment on the aluminum-lithium alloy electron beam welding head in the air circulation furnace. The process is to weld the aluminum-lithium alloy The electron beam welding head is heated to 510°C, kept for 1h, and water-cooled and quenched;

[0031] In the second step, the welded joint after solution treatment is subjected to aging treatment at 150°C×14h in a blast drying oven;

[0032] In the third step, the welded joint after the first aging treatment is subjected to aging treatment at 160°C×12h in a blast drying oven;

[0033] In the fourth step, the welded joint after the second aging treatment is subjected to aging treatment at 130° C. for 16 hours in a blast drying oven.

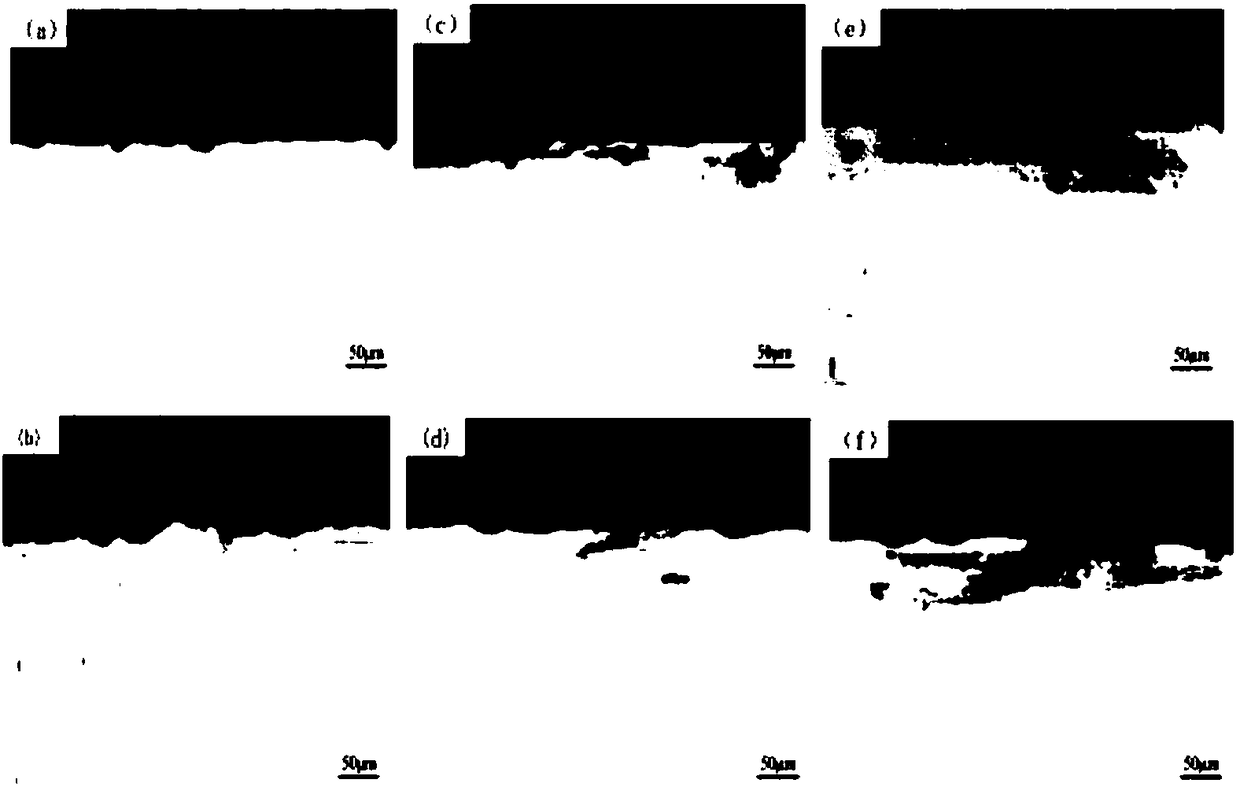

[0034] The intergranular corrosion test was carried out on the aluminum-lithium alloy electron beam welded joints after solid solution + three-stage ag...

Embodiment 2

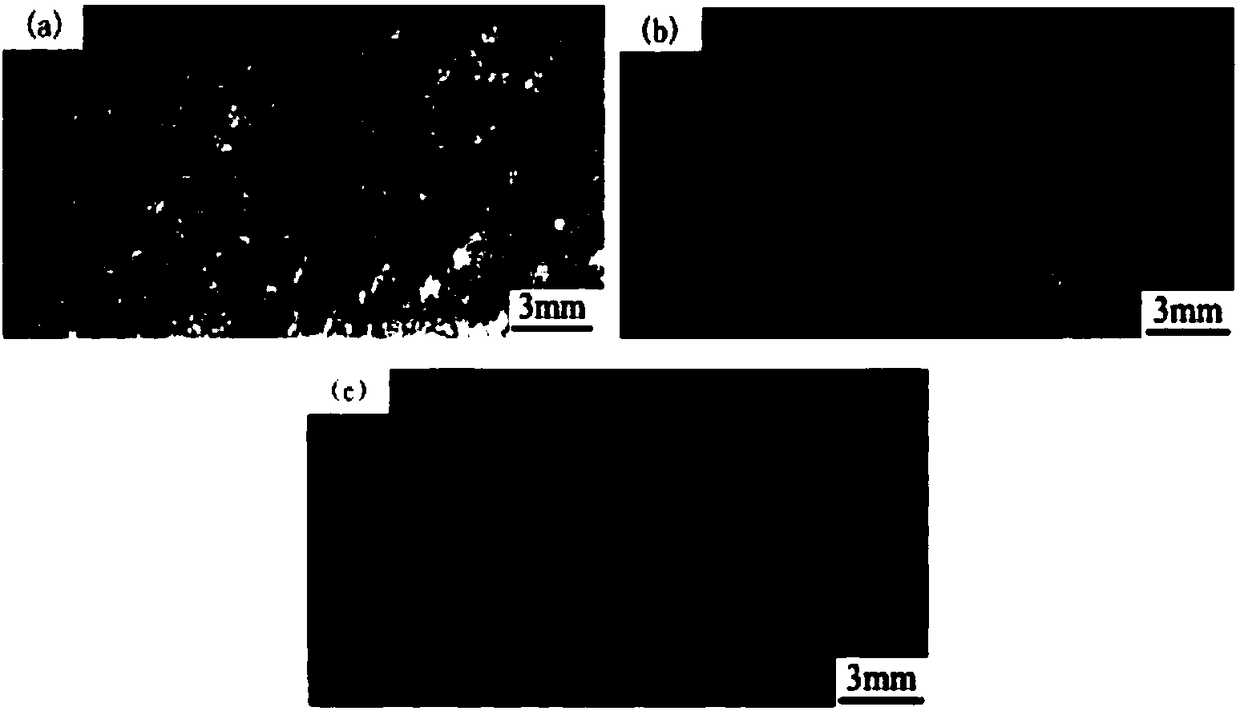

[0038] According to the method of Example 1, the aluminum-lithium alloy electron beam welded joint was subjected to post-weld heat treatment. The exfoliation corrosion (referred to as exfoliation corrosion) test was carried out on the aluminum-lithium alloy electron beam welded joints with post-weld solid solution + three-stage aging treatment to analyze and evaluate the sensitivity of post-weld solid solution + three-stage aging treatment joints to exfoliation, and compared with the welded state The sensitivity of the lower joint to denudation was compared. Exfoliation Corrosion (EXCO) was carried out according to ASTM G 34-2001 standard, and the solution system was EXCO solution (4.0mol L -1 NaCl+0.5mol L -1 KNO 3 +0.1mol·L -1 HNO 3 ), the ratio of solution volume to sample area is 20mL / cm 2 , the test temperature is (25±3)°C, observe intermittently after soaking, and take pictures of the macroscopic appearance of the sample after washing off the corrosion products; com...

Embodiment 3

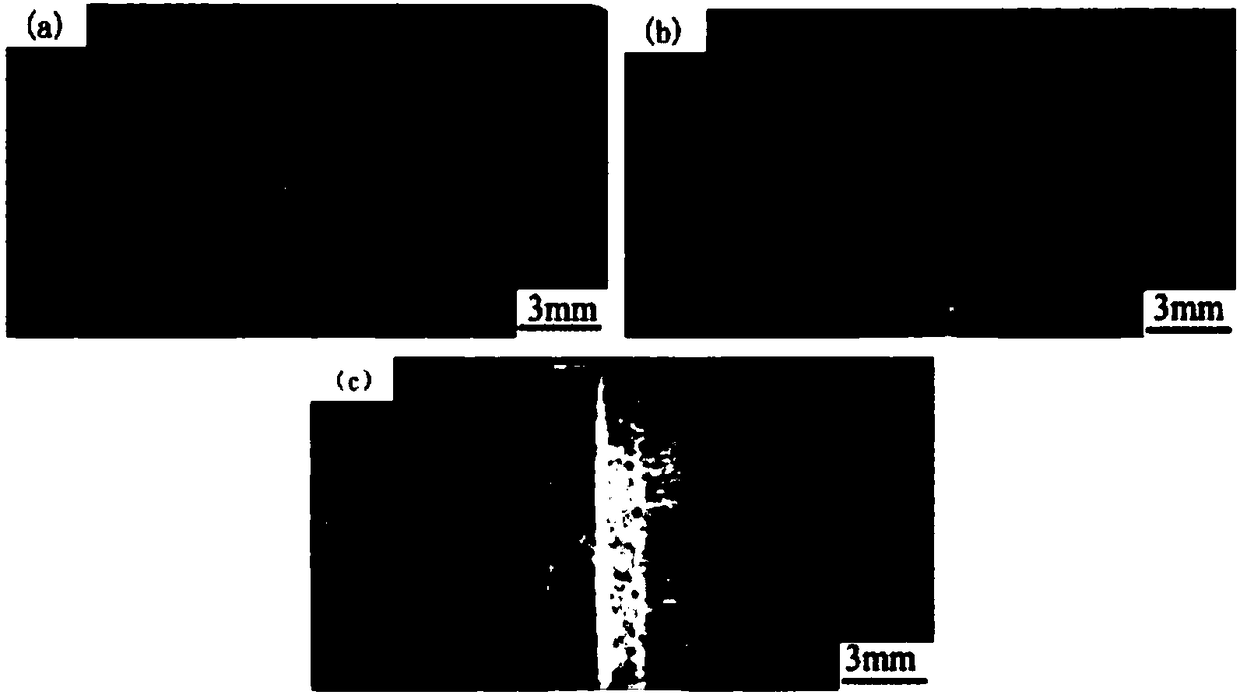

[0047] According to the method of Example 1, the aluminum-lithium alloy electron beam welded joint was subjected to post-weld heat treatment. According to the method of Example 2, the exfoliation corrosion test was carried out on the aluminum-lithium alloy electron beam welded joint. Analyze and evaluate the sensitivity of post-weld solution + three-stage aging treatment joints to exfoliation corrosion, and carry out post-weld solution + two-stage aging treatment (solution treatment: 510℃×1h, water cooling and quenching; two-stage aging: 160℃ ×16h+130℃×16h) Al-Li alloy electron beam welded joints were compared for exfoliation corrosion sensitivity.

[0048] Figure 4 It is the photo of the exfoliation corrosion morphology of the post-weld solid solution + dual-stage aging treatment joint sample. Table 3 is the rating of the erosion degree of the post-weld solid solution + dual-stage aging treatment joint samples according to the ASTM G34-2001 standard.

[0049] Table 3 Corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com