Preparation method of integrated nickel-based porous nickel phosphide hydrogen evolution electrode

A technology of nickel phosphide and porous nickel, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of less active sites for hydrogen evolution and insufficient stability, and achieve good stability, simple and easy method, catalytic The effect of high hydrogen evolution activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

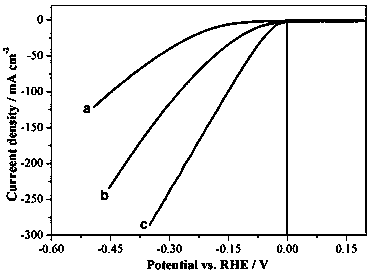

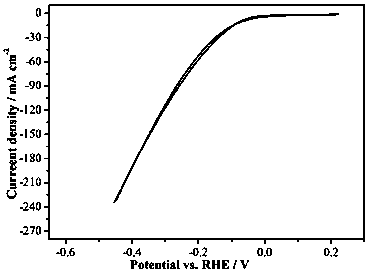

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation method of integrated nickel-based porous nickel phosphide hydrogen evolution electrode,

[0025] Step 1, put the nickel foam substrate into a 3mol / L dilute hydrochloric acid solution for 20 minutes and ultrasonically wash it with deionized water, then place it in ethanol for 30 minutes of ultrasonic treatment to obtain a clean nickel foam substrate;

[0026] Step 2, preparation molar concentration is the hydrofluoric acid aqueous solution of 0.01mol / L;

[0027] Step 3, adding the foamed nickel substrate prepared in step 1 to the hydrofluoric acid aqueous solution prepared in step 2; then etching and reacting at 100°C for 5 hours to form a nickel-based porous nickel precursor;

[0028] Step 4, taking out the nickel-based porous nickel precursor obtained after the treatment in step 3, washing with deionized water and drying;

[0029] Step 5, the nickel-based porous nickel precursor and sodium hypophosphite were heated at 400 °C in 4% H 2 -A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com