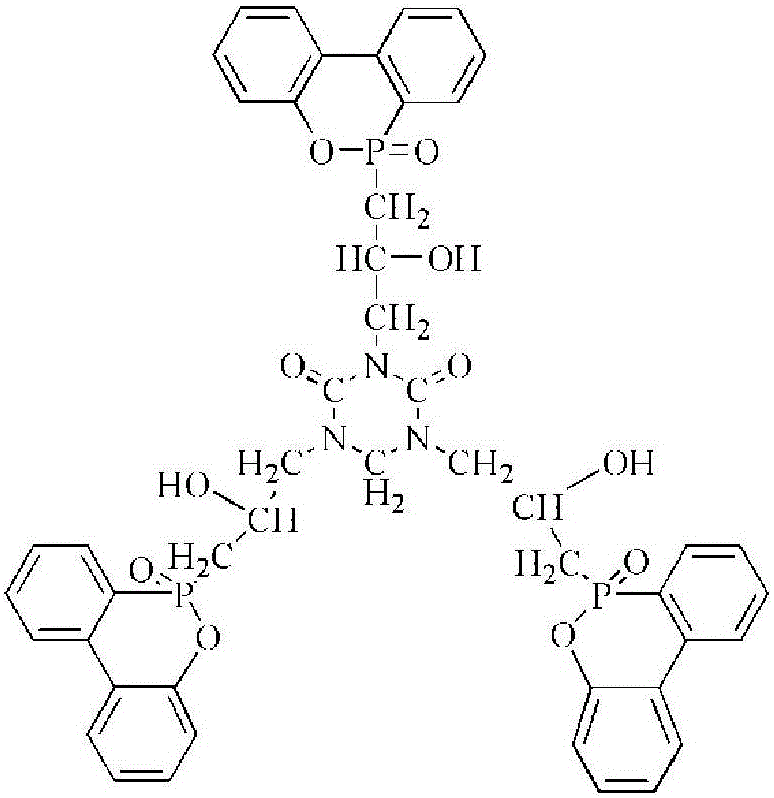

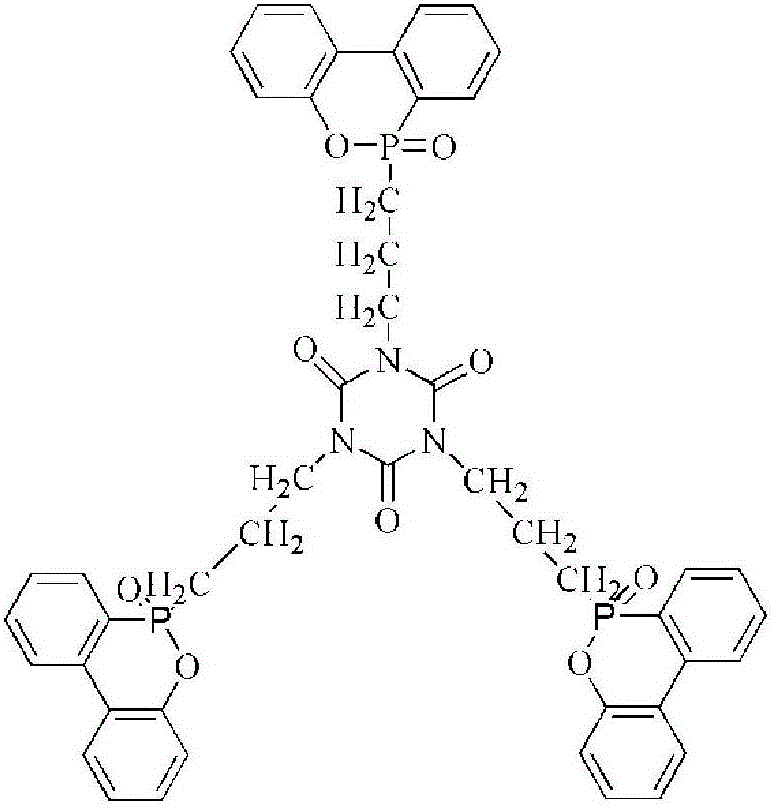

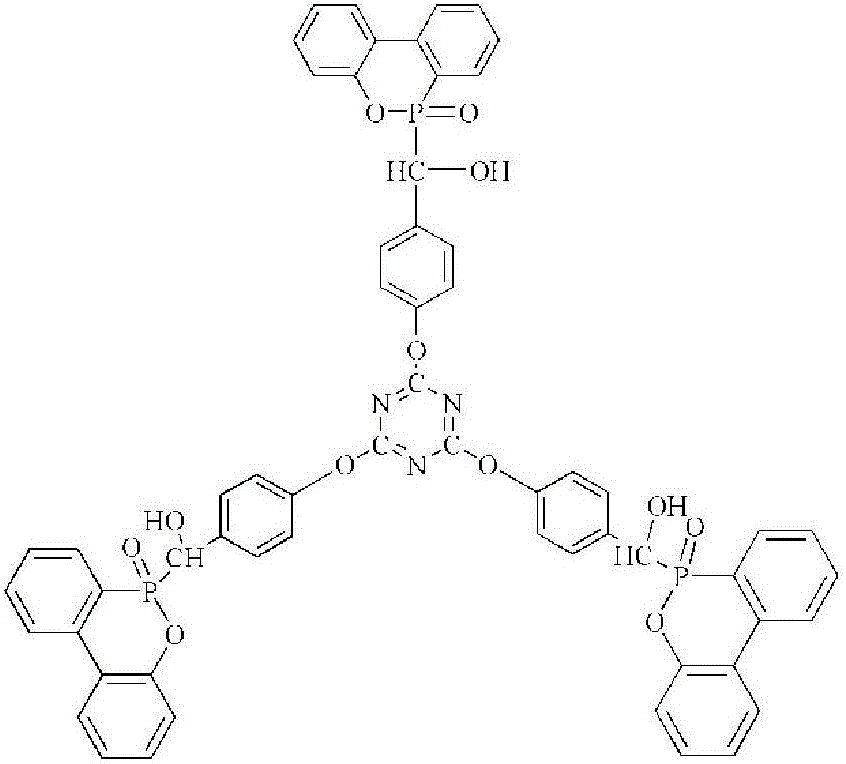

Phosphaphenanthrene triazine double-radical compound attached fire-retardant fibers and preparation method thereof

A technology of flame retardant fibers and compounds, applied in the directions of flame retardant fibers, fiber processing, textiles and papermaking, etc., can solve the problems of poor stability and compatibility, general flame retardant effect, and limited application of polyester fabrics. Excellent processing performance, low combustion toxicity, convenient for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Put 5g of TAIC-DOPO, 50g of polyurethane resin, and 10g of toluene into a stirring pot, mix and stir evenly at 25°C to form a uniform coating glue, coat the coating glue on the fiber, and dry it at 150°C for 3 minutes. The LOI of the obtained flame-retardant fiber was 23.3%, and the tensile strength was 51.7 MPa.

Embodiment 2

[0039] Put 30g of TGIC-DOPO, 80g of polyurethane resin, and 15g of xylene into a stirring pot, mix and stir at 20°C for 0.1h to form a uniform coating glue, coat the coating glue on the fiber, and dry at 170°C After 2 minutes, the LOI of the obtained flame-retardant fiber was 23.9%, and the tensile strength was 52.7 MPa.

Embodiment 3

[0041] Put 8g of TAIC-DOPO, 70g of polyurethane resin, 12g of aluminum diethylphosphinate, and 12g of xylene into a stirring pot, mix and stir at 50°C for 0.3h to form a uniform coating glue, and coat the coating glue On the polyester fabric, drying at 180°C for 10 minutes, the LOI of the obtained flame-retardant polyester fabric is 26.7%, and the tensile strength is 54.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com