Wear-resistant organosilicone synthetic leather and manufacturing method thereof

A technology for organosilicon synthetic leather and a production method, which is applied in textiles and papermaking, etc., can solve the problems of poor abrasion resistance, short service life of organosilicon synthetic leather, and limit the application range of organosilicon synthetic leather, so as to expand the application range and extend the The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

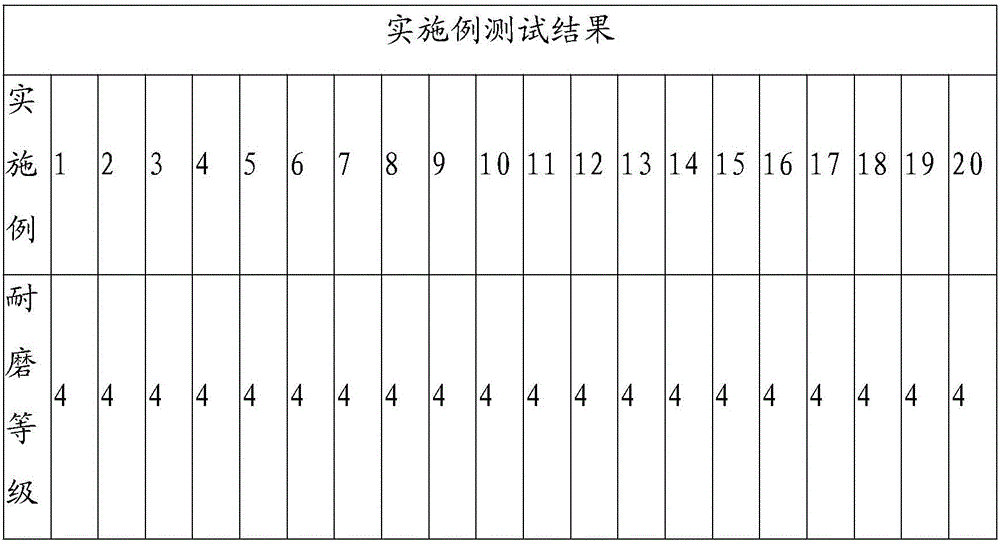

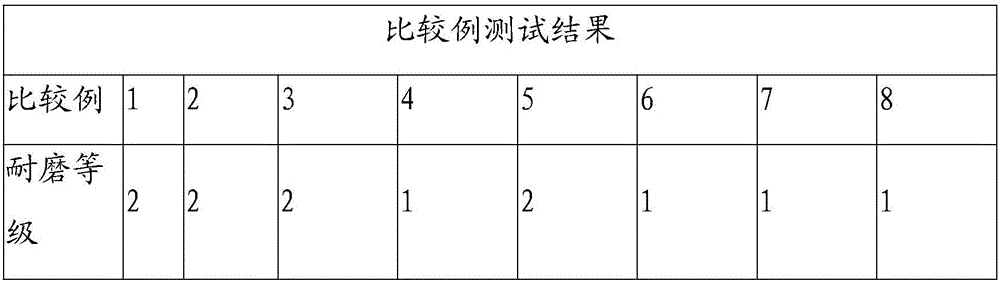

Examples

Embodiment 1

[0024] 28.9g of vinyl polydimethylsiloxane with a viscosity of 50000mpa.s, 10g of white carbon black, 5g of spherical silicone resin, 1g of a platinum catalyst with a Pt atom content of 3000ppm, 0.1g of methyl butynol, 1g of hydrogen-containing Mix 0.75% hydrogen-containing silicone oil, 50g white electric oil, and 5g white corundum with a particle size of 400 meshes. At the same time, add a silane coupling agent to promote the uniform dispersion of the white corundum, and obtain a wear-resistant rubber. Vinyl polydimethyl Silicone is a vinyl-terminated silicone oil. Coat the wear-resistant rubber on the release paper with a coating thickness of 0.05mm. After coating, bake at 80°C-150°C for 2-10 minutes, and vulcanize the wear-resistant rubber to form a wear-resistant surface rubber layer. Then apply liquid silica gel on the surface of the wear-resistant rubber layer with a coating thickness of 0.1mm. After coating, bake at 80°C-150°C for 2-10 minutes to form the first primer ...

Embodiment 2

[0026] The production method of this example is the same as that of Example 1, only the weight of vinyl polydimethylsiloxane in the wear-resistant rubber is adjusted to 27.9g, and the finished product A2 is finally obtained through the same follow-up process .

Embodiment 3

[0028] The production method of this embodiment is the same as that of Example 1, only the weight of vinyl polydimethylsiloxane in the wear-resistant rubber is adjusted to 27.9g, and the weight of white corundum is adjusted to 6g. The process, finally made the finished product A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com