A kind of rapid separation detection method of vinyltriazole product

A vinyltriazole and detection method technology, which is applied in material separation, measuring devices, and analytical materials, etc., can solve the problems of difficult sample recovery, poor safety, and low precision of gas chromatography, and achieve reduced retention time and rapid separation and detection , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032]The preparation method of the vinyl triazole product in the embodiment 1-5 is: the vinyl triazole product obtained by the elimination reaction of triazole and vinyl acetate is obtained after vacuum distillation, extraction, distillation and concentration, specifically For: 150ml (1.62mol) of vinyl acetate, 0.2g of hydroquinone, 9.5g of mercury acetate, 9.6ml of trifluoroacetic acid, 37.0g (0.51mol) of 1,2,4-triazole Add it to a 500ml flask connected with a spherical condenser, and add a magnet to it, stir it vigorously under normal temperature for 10-20min, heat it in an oil bath, and control the reaction temperature to 70°C. The reaction was carried out under the protection of nitrogen. After reacting for 3 hours, stop heating and stirring, and let it stand for cooling. At this time, the solution was dark brown. The solution in the flask was distilled under reduced pressure, and the unreacted vinyl acetate was evaporated under reduced pressure. The remaining liquid in ...

Embodiment 1

[0035] A rapid separation and detection method of a vinyltriazole product in this embodiment comprises the following steps:

[0036] S1. Take 40 microliters of the product and mix it into 3ml of a mixture of acetonitrile and water with a volume ratio of 70:30 to obtain a sample solution to be tested;

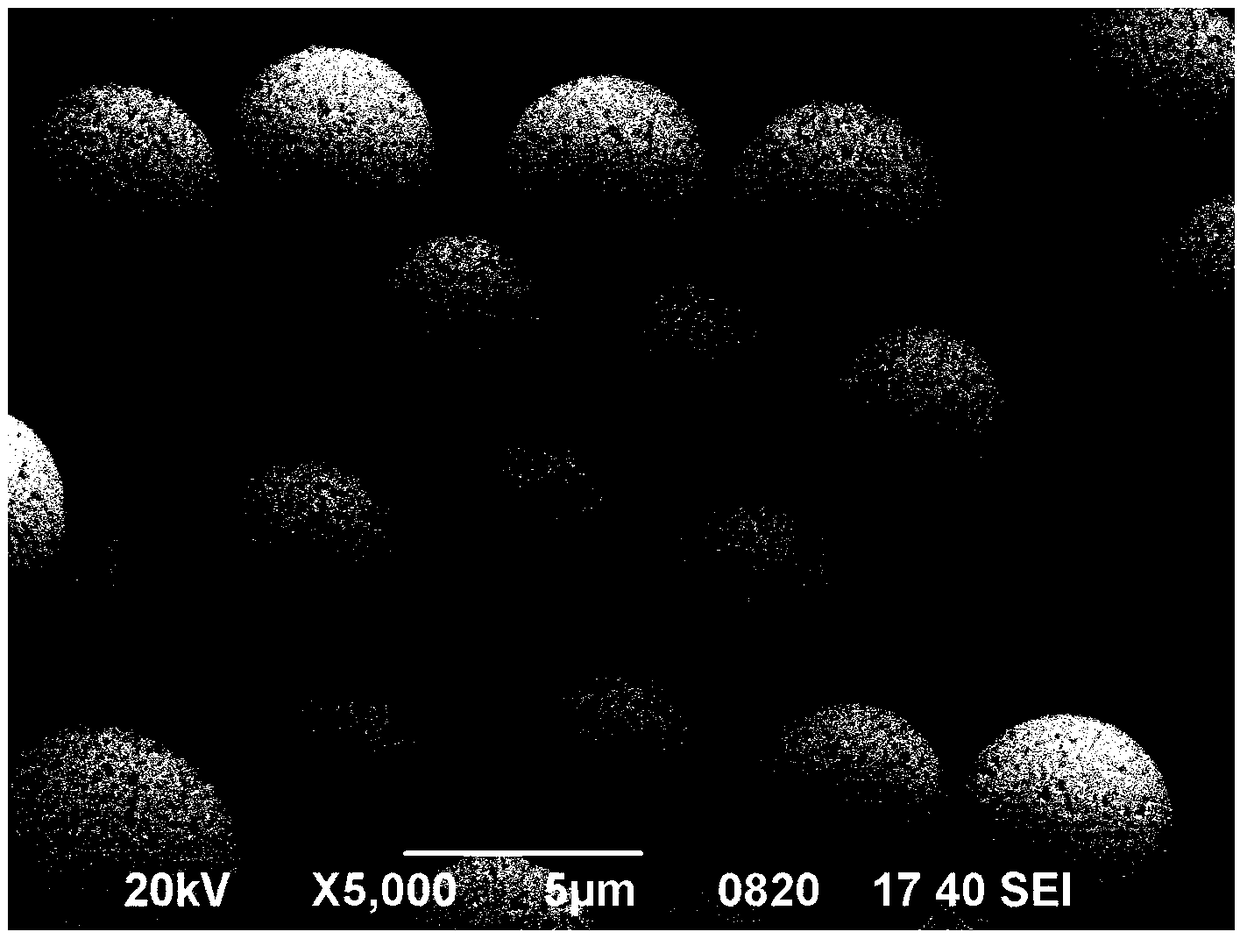

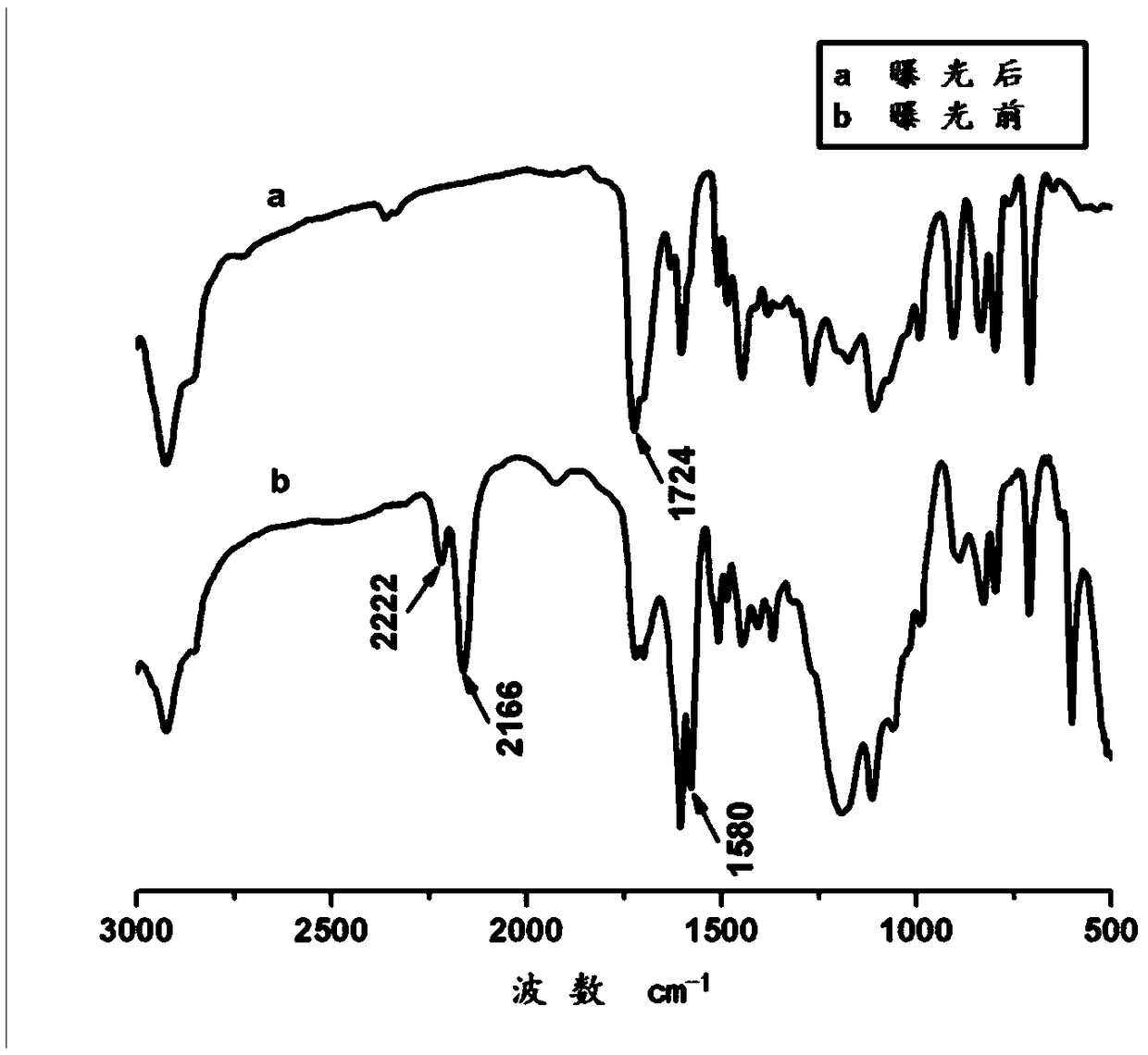

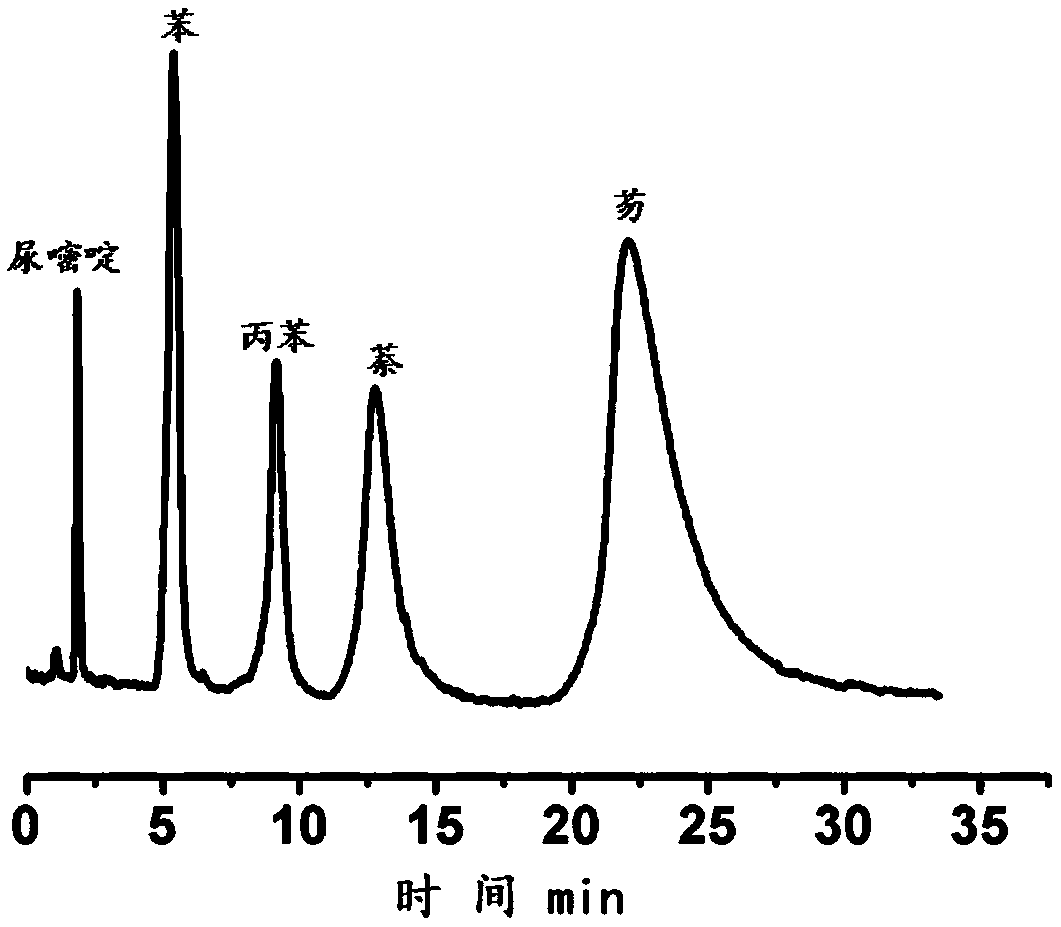

[0037] S2, HPLC separation and detection: Disperse 1.25 g of porous polyglycidyl methacrylate microspheres modified by diazo resin in 20 ml of isopropanol, and use a mixture of methanol and isopropanol with a volume of 1:1 as The pressurized liquid was packed into a stainless steel chromatographic column with a height of 75mm and a diameter of 4.6mm by a column packing machine, and the vinyltriazole product sample was separated from the liquid to be tested at a flow rate of 0.5ml / min. Such as Figure 4 As shown, the curve a is the separation effect of the porous microspheres modified by the diazo resin prepared in this example on the vinyl triazole product, and the results show...

Embodiment 2

[0047] A rapid separation and detection method of a vinyltriazole product in this embodiment comprises the following steps:

[0048] S1. Take 50 microliters of the product and mix it into 3.5ml of the mixed solution of acetonitrile and water with a volume ratio of 65:35 to obtain the sample solution to be tested;

[0049] S2. HPLC separation and detection: Disperse 1.40 g of porous polyglycidyl methacrylate microspheres modified by diazo resin in 20 ml of isopropanol, and add a mixture of methanol and isopropanol with a volume of 0.9:1.1. Pressure liquid, packed into a stainless steel chromatographic column with a height of 75 mm and a diameter of 4.6 mm by a column packing machine, with a mixture of acetonitrile and water at a volume ratio of 65:35 as the mobile phase, at a temperature of 25 ° C, the flow rate is 0.6ml / min, the vinyltriazole product sample liquid to be tested was separated by high performance liquid chromatography, showing a good separation effect.

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com