Quantum dot light-doped graphene/boron nitride/gallium nitride ultraviolet detector and manufacturing method thereof

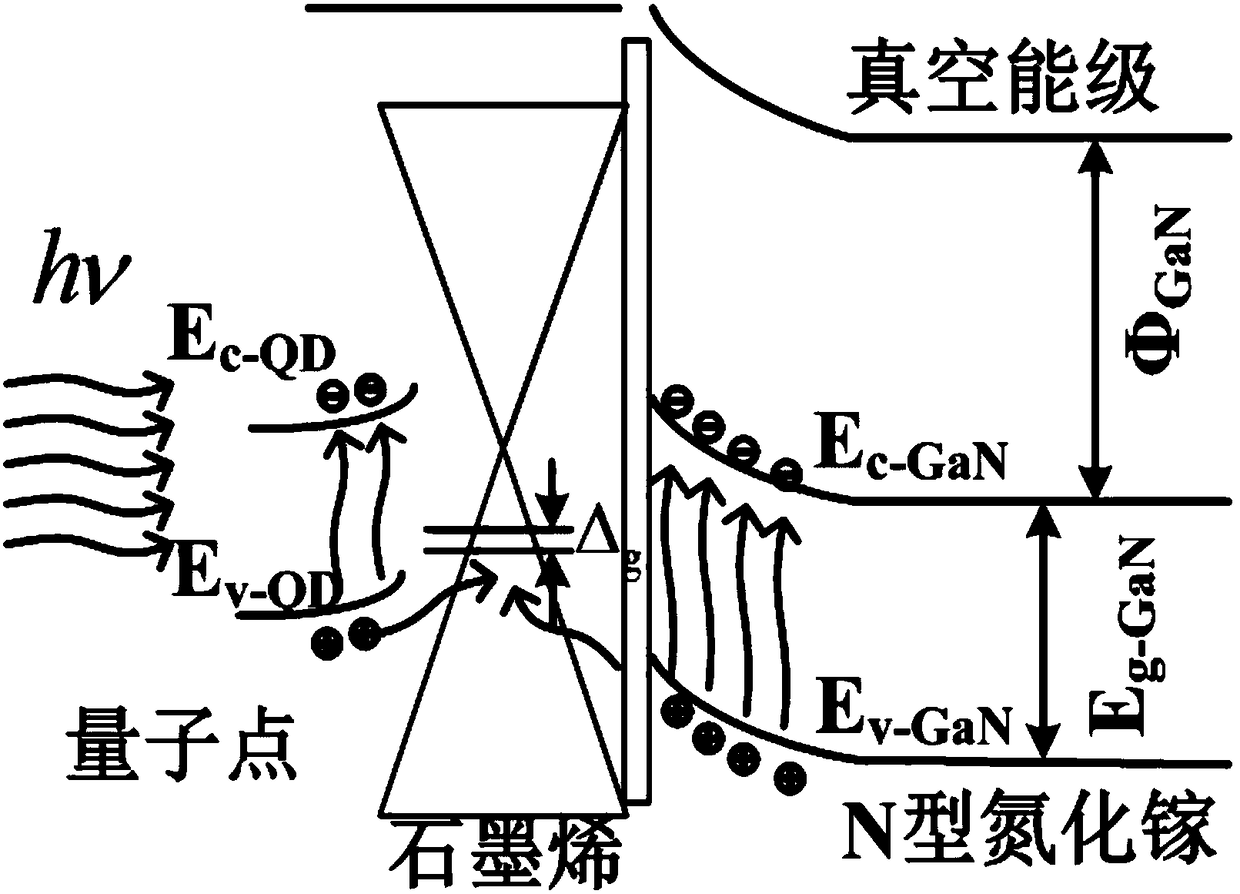

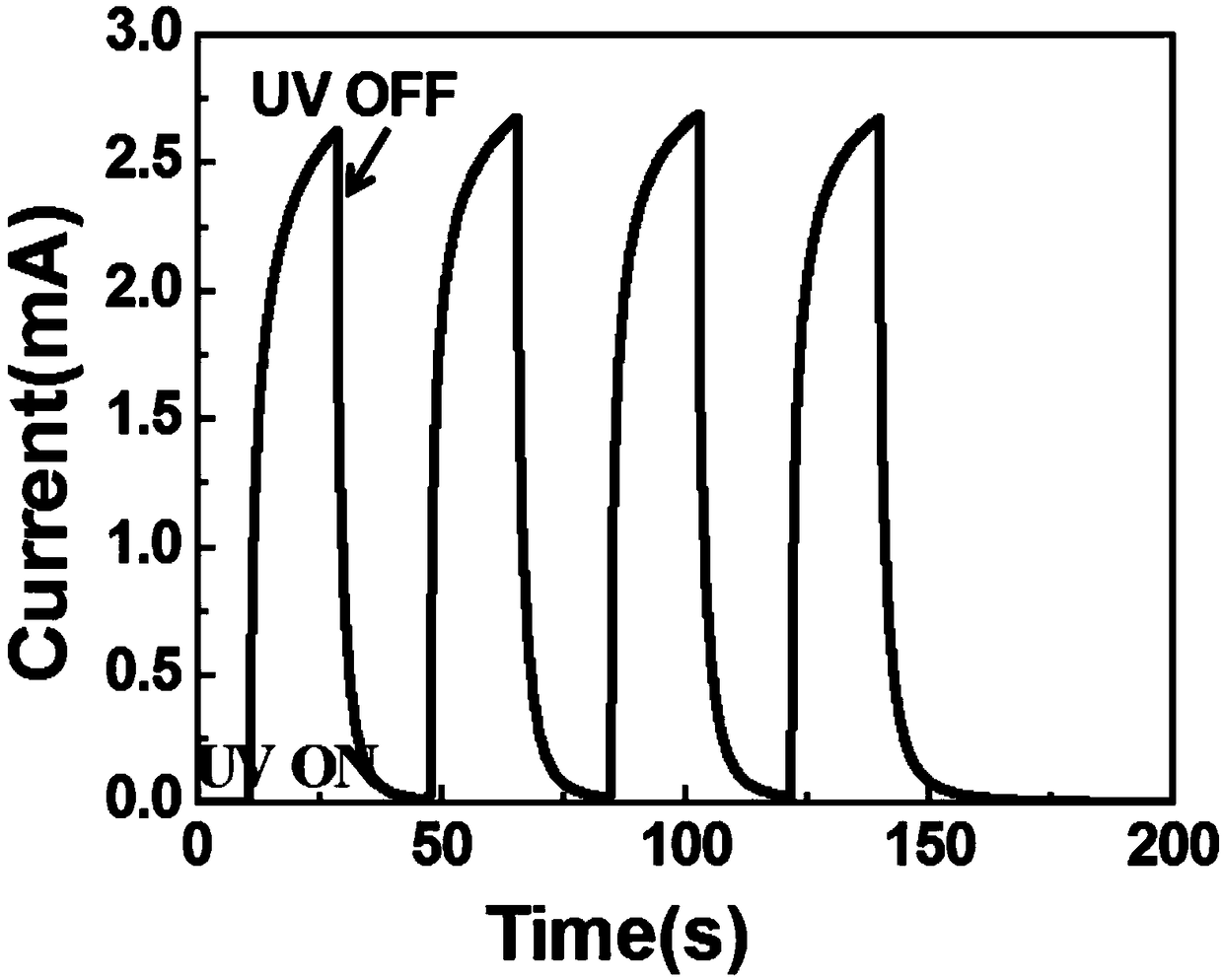

A technology of graphene and quantum dots, which is applied in quantum dot light-doped graphene/boron nitride/gallium nitride ultraviolet photodetectors and its preparation, and in the field of ultraviolet photodetectors and their preparation, which can solve the problem of affecting the detector light. Problems such as detection responsivity and detection degree, to achieve good light absorption and light detection response performance, easy to implement, and high carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

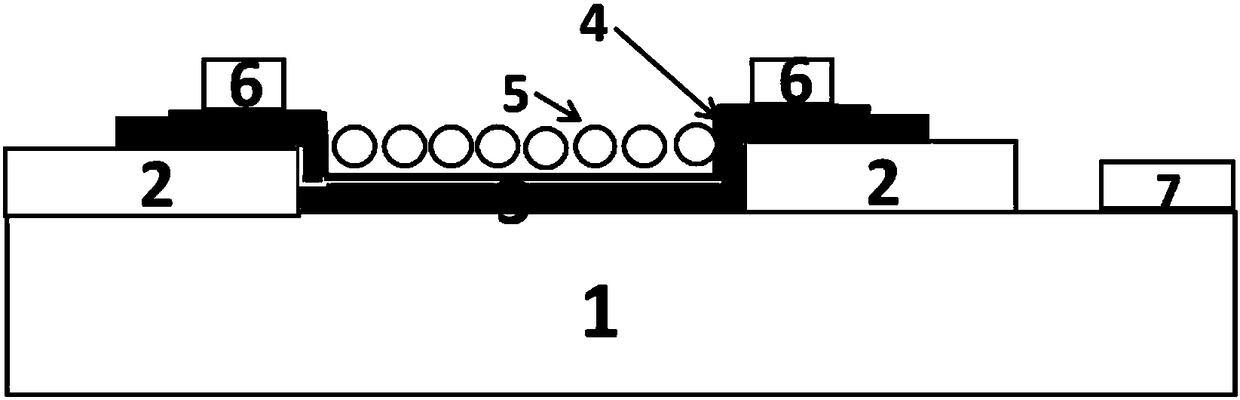

[0022] 1) On the front side of the N-type doped sapphire substrate gallium nitride wafer, make a side electrode in a certain area, the material is 100nm nickel / gold electrode, and the area accounts for about 5% of the entire front gallium nitride substrate, and then Immerse in acetone and isopropanol solutions successively for surface cleaning, wash with deionized water, take out and dry;

[0023] 2) A layer of 80nm silicon nitride (SiN x ) an insulating layer, the area of which is about 80% of the entire GaN substrate, and a certain area (2mm*2mm) is left in the middle area of the insulating layer without an insulating layer, that is, a window;

[0024] 3) transferring the single-layer graphene to boron nitride, the area of boron nitride is larger than the area of single-layer graphene and larger than the blank area in the middle of the insulating layer, and the thickness of the boron nitride is 5nm;

[0025] 4) transfer the boron nitride on which the graphene is tra...

Embodiment 2

[0029] 1) On the front side of the N-type doped sapphire substrate gallium nitride wafer, make a side electrode in a certain area, the material is 100nm chromium / gold electrode, and the area accounts for about 5% of the entire front gallium nitride substrate, and then Immerse in acetone and isopropanol solutions successively for surface cleaning, wash with deionized water, take out and dry;

[0030] 2) A layer of 80nm silicon nitride (SiN x ) an insulating layer, the area of which is about 90% of the entire gallium nitride substrate, and a certain area (1mm*1mm) is left in the middle area of the insulating layer without an insulating layer;

[0031] 3) transferring single-layer graphene to boron nitride requires that the area of boron nitride be larger than the area of single-layer graphene and larger than the blank area in the middle of the insulating layer;

[0032] 4) transfer the boron nitride on which the graphene is transferred as a whole to the above-mentioned ga...

Embodiment 3

[0035] 1) On the front side of the N-type doped sapphire substrate gallium nitride wafer, make a side electrode in a certain area, the material is 200nm chromium / gold electrode, and the area accounts for about 5% of the entire front gallium nitride substrate, and then Immerse in acetone and isopropanol solutions successively for surface cleaning, wash with deionized water, take out and dry;

[0036] 2) A layer of 80nm silicon nitride (SiN x ) an insulating layer, the area of which is about 90% of the entire gallium nitride substrate, and a certain area (1mm*1mm) is left in the middle area of the insulating layer without an insulating layer;

[0037] 3) Transferring three layers of graphene to boron nitride requires that the area of boron nitride be larger than the area of single-layer graphene and larger than the blank area in the middle of the insulating layer;

[0038] 4) transfer the boron nitride on which the graphene is transferred as a whole to the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com